Quenching is a heat treatment process for metals and glass. Heating alloy products or glass to a certain temperature, then rapidly cooling in water, oil, or air containing minerals, generally used to increase the hardness and strength of the alloy.

What Is Quenching?

Hardened steel refers to the steel whose structure is martensite after being quenched and whose hardness is greater than HRC50. It occupies a considerable proportion of difficult-to-cut materials.

There are several key points in the selection of hardened steel processing tools:

First, The cutting characteristics of quench:

- High hardness, high strength, and almost no plasticity: this is the main cutting feature of quenched steel. When the hardness of the quenched steel reaches HRC50-60, its strength can reach σb=2100-2600MPa. According to the work-ability classification requirements of the processed material, the hardness and strength of the quenched steel are 9a, which is the most difficult to cut material.

- High cutting force and high cutting temperature: cutting chips from high hardness and high strength work pieces, the unit cutting force can reach 4500MPa. To improve the cutting conditions and increase the heat dissipation area, the cutter chooses smaller primary and secondary declination angles. At this time, it will cause vibration, which requires good rigidity of the processing system.

- It is not easy to produce a built-up edge: the hardened steel has high hardness and high brittleness. It is not easy to generate a built-up edge during cutting, and the processed surface can obtain lower surface roughness.

- The cutting edge is easy to break and wear: due to the high brittleness of the quenched steel, the cutting chips and the cutting edge are in short contact during cutting, and the cutting force and cutting heat are concentrated near the cutting edge of the cutting tool, which is easy to break and wear the cutting edge.

- Low thermal conductivity: The thermal conductivity of general quenched steel is 7.12W/(m•K), which is about 1/7 of No. 45 steel. The mach-inability grade of the material is grade 9a, which is difficult to cut. Due to the low thermal conductivity of hardened steel, it is difficult to remove the cutting head through the chips, the cutting temperature is very high, and the tool wear is accelerated.

Second, Material selection of quench processing tools

Reasonable selection of tool materials is an important condition for cutting hardened steel. According to the cutting characteristics of hardened steel, the tool material must not only have high hardness, wear-resistance, and heat resistance but also have a certain strength and thermal conductivity. The tool materials for processing hardened steel are:

- Cemented carbide: When choosing cemented carbide, the material of cemented carbide with an appropriate number of ultrafine particles of TaC or NbC should be selected first. Because after adding TaC to WC-Co cemented carbide, its original high-temperature strength at 800℃ can be increased by 150~300MPa, and the hardness at normal temperature can be increased by HV40~100. The cemented carbide grades commonly used for cutting hardened steel are YM051, YM052, YN05, YN10, 600, 610, 726, 758, 767, 813, etc.

- Hot-pressed composite ceramics and hot-pressed silicon nitride ceramics: adding metal elements such as TiC to Al2O3 and using a hot-pressing process improves the compactness of ceramics, improves the performance of alumina-based ceramics, and increases its hardness By HRA95.5, the flexural strength can reach 800~1200MPa, and the heat resistance can reach 1200℃~1300℃, which can reduce bonding and diffusion wear during use.

- Cubic boron nitride composite sheet (PCBN) tool: its hardness is HV8000~9000, composite bending strength is 900~1300MPa, thermal conductivity is relatively high, heat resistance is 1400℃~1500℃, which is the highest among tool materials It is very suitable for the finishing of hardened steel. The integrated CBN insert BN-S20, which was developed later, increased the application field of the CBN insert, and can be widely used in rough machining and intermittent machining.

Third, Hardness selection of experience points for selection of quenched steel processing tools

If it is an occasional production of a single piece, it can be processed with ordinary carbide tools of the appropriate brand. If the hardened steel is processed in batches, it can be selected from three kinds of tool materials: coated carbide, ceramic tools, and CBN tools according to the hardness and machining allowance of the workpiece.

- The quenched and tempered parts with Rockwell hardness below 45 HRC are suitable for the selection of coated carbide tools, which require relatively low-speed turning.

- For the machining of workpieces with a hardness of HRC40-55 degrees after quenching, ceramic blades are suitable, but intermittent turning should be avoided as much as possible. If the machining allowance is large or there is intermittent machining, the cubic boron nitride tool can be used.

- For workpieces with hardness above HRC55 after quenching, it is recommended to choose CBN cubic boron nitride cutters. The machining allowance is small. If the margin on one side is less than 30 wires, welding composite cubic boron nitride cutters can be selected. Generally, the depth of the knife is better than 0.3mm.

If the machining allowance is large, and the margin is more than 1mm on a single side, it is recommended to choose the integral CBN tool BN-S20, which can process hardened steel with a large number of cutters, reduce the number of passes, and improve the machining efficiency.

Fourth, The cutting methods of quench processing tools selection experience points

Carbide cutting tools and ceramic inserts are generally heat-resistant and require wet cutting when machining hardened steel. The thermal conductivity and heat resistance of the cubic boron nitride blade is very good. It can perform dry cutting under high-speed cutting without adding cutting fluid, which is green and environmentally friendly.

Note: If the cutting conditions of small holes or cutting fluid must be increased, you need to communicate with the tool engineer in advance to choose the wet-cut cubic boron nitride grade.

Fifth, Cutting parameters for the selection of experience points of quenched steel processing tools

The cutting parameters of cutting hardened steel are mainly selected according to the physical and mechanical properties of the tool material and workpiece material, the shape of the work piece, the rigidity of the processing system and the machining allowance. When selecting the three elements of cutting amount, first consider choosing a reasonable cutting speed, followed by the cutting depth, and then the feed amount.

When cutting materials with a hardness of HRC55-65, the cutting speed of the CBN tool should be 50-120m/min. Vc during milling=100~160m/min, feed per minute Vf=70~160mm/min; Vc=60~130m/min during reaming, ap=0.1~0.2mm, f=0.07~0.2mm/r . It should be noted that the use of cubic boron nitride tools for fine turning hardened steel, the workpiece hardness is higher than 45HRC, the best effect, the higher the hardness of the work piece, the lower the cutting speed, such as the work piece hardness of 70HRC, the cutting speed should be 60-80m/min is selected; when the cutting depth of the precision turning is 0.1~0.3mm, the feed amount is 0.05~0.025mm/r, the surface roughness of the work piece after finishing is Ra0.3~0.6μm, and the dimensional accuracy can reach 0.013mm. If it can be processed by a standard CNC lathe with good rigidity, the rigidity of the tool is good and the cutting edge is sharp, the surface roughness of the work piece after finishing turning can reach Ra0.3μm, and the dimensional accuracy can reach 0.01mm, which can reach the level of processing with a CNC grinder.

Sixth, The experience points of the selection of quenching steel processing tools, the use of turning instead of grinding tools

Feasibility of replacing grinding when hard turning steel with cubic boron nitride (CBN) tool

- Cutting complex surfaces and several complex surfaces on CNC machine tools can replace the grinding process, can reduce the labor of 1/3 to 2/3, and can ensure high position accuracy.

- Inner holes or small holes with complicated shapes. If grinding is used, the shape of the grinding wheel is required to be correspondingly complicated, and sometimes it cannot be ground. At this time, turning is the most advantageous.

- Several surfaces of a part (outer circle, inner hole, end face, stage, groove) need to be ground, and then turning is used, which can be completed in one process, and the tooling used for grinding can be subtracted.

- After quenching, the parts are easy to deform and the remaining margin is small, which is easy to cause waste products. At this time, the remaining margin can be larger. After quenching, the CBN tool is used to cut off the excess margin, and then grind to reduce the occurrence of large deformation Scrap.

- The surface high-frequency parts used under difficult conditions with large fluctuations in processing load are processed with CBN tools. The surface structure and physical and mechanical properties of the work piece are better than those of grinding, which can extend the service life of the parts.

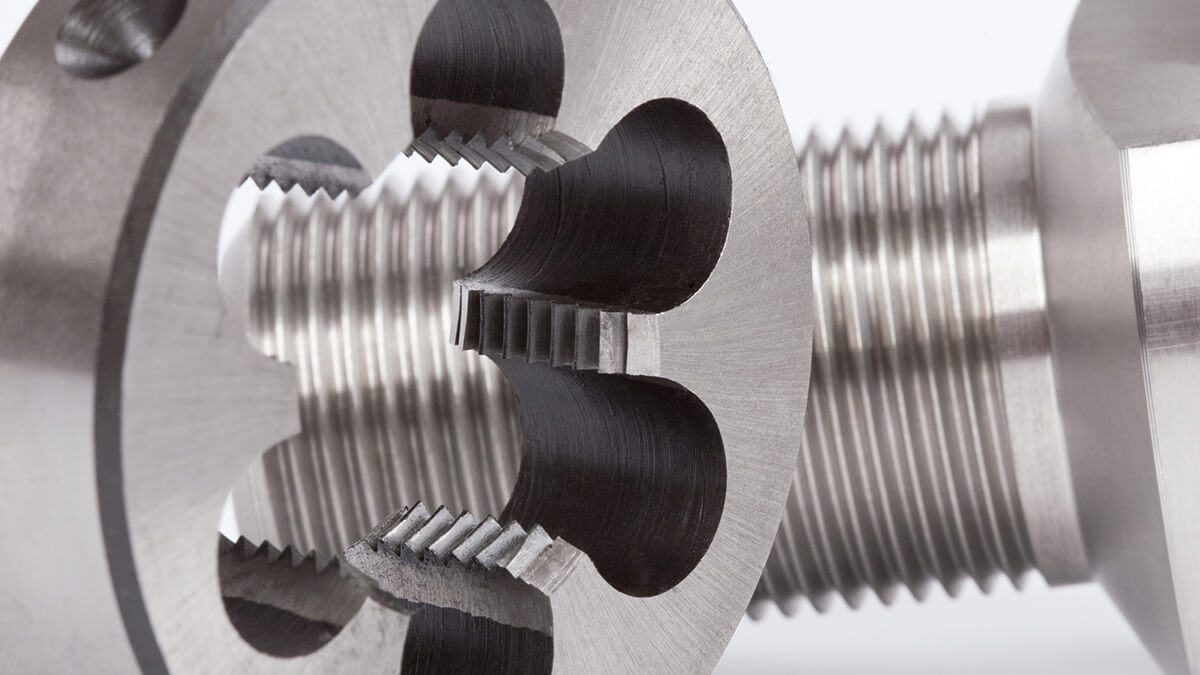

Seventh, Thread processing for the selection of experience points for quenching steel processing tools

After quenching, the thread of the thread rolling wheel is generally ground by a thread grinder. But to improve the processing efficiency and solve the difficulty without thread grinding, it can also be processed by turning.

- Technical requirements for thread rolling wheel: the material of the blank is Cr12MoV alloy tool steel, the hardness is HRC59 after quenching, the pitch is 1.5mm, the number of thread heads is 10, the half-angle α/2=30º±25′, the tooth depth It is 0.922mm, the tooth tip height h1 = (0.435±0.042) mm, and the tooth root height h2 = (0.487(+0.010/-0.029)mm.

- Machine tool and cutter: The machine tool is a type 8955 290mm shovel tooth lathe produced by Dalian, and the attachment of the machine tool is an index plate. The tools are divided into rough turning tools and fine turning tools. The tool geometry parameter is: γ. = -3º, α. =5º, α'=0º~2º, εr=60º20', λs=-5º, the front blade is inclined by 3º facing the spiral direction. After grinding the tools at all angles, grind them with diamond whetstones, and produce negative chamfers at the main and auxiliary blades and the tip of the blade.

- Cutting amount: cutting speed 26.2m/min, rough turning thread aP=0.1~0.15mm, finishing turning aP=0.05~0.08mm. In turn, each time the tool is moved, the head is divided once to ensure that each tooth is evenly removed.

- Precautions: To prevent the tip of the knife from collapsing when cutting in and out, the ends of the thread are inverted by 30º angle. To accurately control the depth of each time the knife is eaten, place a 100-meter dial in the horizontal direction.

Compared with grinding, turning grinding technology has higher processing efficiency than grinding. In hard turning, Valin BN-S20 can use large cutting depth intermittent cutting, coupled with high work piece speed, the metal removal rate is usually 3 to 4 times that of grinding processing, power consumption, and labor, but the material consumables are only 1/5 of grinding.

Risk factors: The clearance and rigidity of the machine tool used for hard turning determine the probability of the occurrence of vibration knife and tool letting problems, and will also affect the dimensional accuracy and surface roughness of the processed work piece, so the user needs to consult and select according to his work piece requirements.

.jpg)

.png)