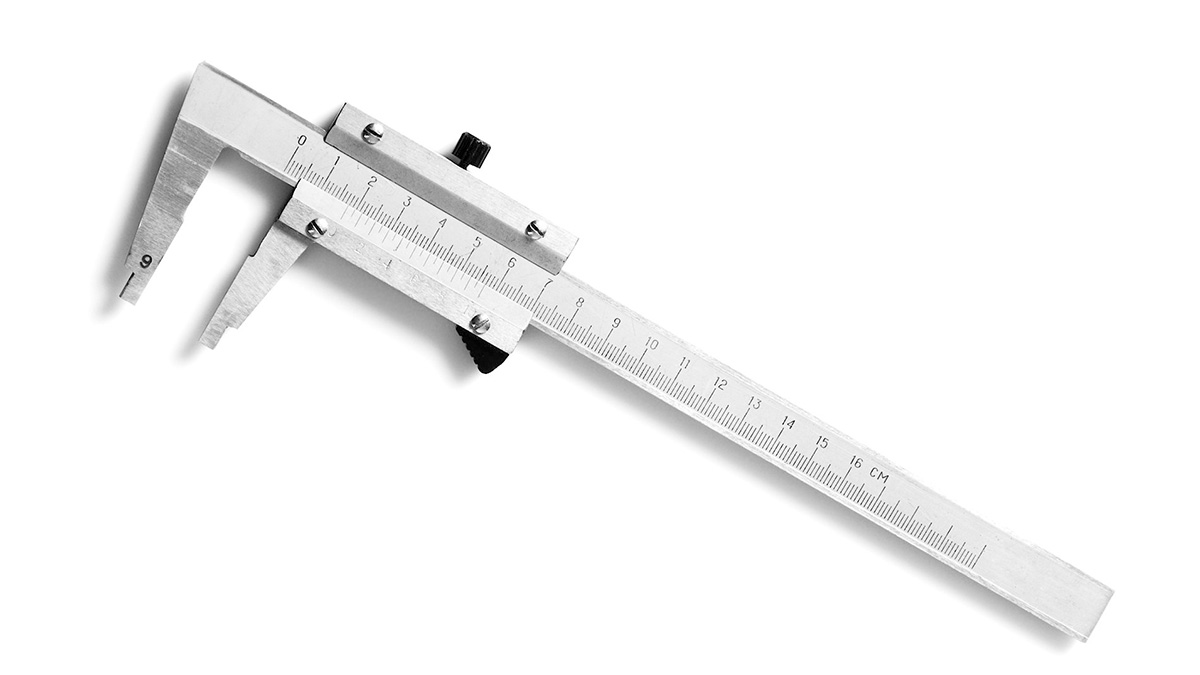

One of the tools a mechanic must use is a caliper. Although not as accurate as a micrometer, the caliper is a convenient and practical tool that can help mechanics quickly measure parts and use the measurement results to evaluate subsequent processing.

Vernier caliper is a relatively common measuring instrument for a fitter, machining, quality control, and other personnel. Vernier caliper is an indispensable tool for ironwork. The vernier caliper can measure the length, width, height, and depth of objects and the inner and outer diameter of the ring. The vernier caliper accuracy is generally 0.02mm, of course, it can also be used for woodworking, and woodworking accuracy only requires 1mm, and it does not need to be too precise.

The working principle of vernier calipers:

The measuring principle is that there is a scale on the main ruler, and there is also a scale on the vernier ruler. The scale on the main ruler is mainly used to display the integer value of the measured object, and the scale of the vernier ruler is mainly used to display the decimal part of the measured object. After adding the integer part and the decimal part, the measured value of the measured object is obtained.

The vernier caliper uses the idea of differentiation to enlarge the readings into easily identifiable scale alignment, so as to achieve high-precision measurement. Vernier calipers have become an important measurement tool in the industry due to their simple structure, convenient operation, and certain measurement accuracy. In middle school, we are required to be proficient in the use of vernier calipers. Usually, there are ten-degree vernier calipers, twenty-minute vernier calipers, and fifty centimeters. Vernier calipers can measure length, depth, and inner and outer diameters in different ways of use.

The composition of vernier calipers

The vernier caliper is mainly composed of two parts, one is the main ruler and the other is the vernier ruler that can slide back and forth along the main ruler. It can be seen from the figure that the main ruler and the vernier ruler constitute the inner and outer measuring jaws. The function of the inner measuring claw is to measure the inner diameter of the pipe mouth and the width of the notch; the function of the outer measuring claw is to measure the outer diameter of the pipe and the thickness of the processed object. At the same time, there is a tail shape on the tail of the micrometer, which is called a depth gauge. This depth gauge is mainly used to measure the depth of the groove or the depth of the pipe.

Types of calipers:

- Calipers can be divided into three main types: vernier calipers, dial calipers, and digital calipers.

- The caliper shape can be divided into M type, C (CM) type, CN type.

- The display mode of the caliper can be divided into cursor type, band meter type, and digital display type.

The function of the vernier caliper:

- Measurements of external dimensions: Measuring the thickness of the work piece and the outer width of the work piece.

- Measurements of internal dimensions: Measures the inner width of the work piece.

- Measurements of depth: Measures the depth of the work piece.

Measuring method of vernier caliper:

- Sizes of the workpiece are measured by the scale of the ruler and the sub ruler.

- When measuring, do not use excessive measuring force.

- When reading the scale, the scale should be read from the front of the scale to avoid errors.

- When measuring the outside, the workpiece shouold be close to the root of the main ruler.

- When measuring the inner side, the inner claw must be parallel and close to the inside of the workpiece in order to achieve the best measurement position.

- To measure the depth, the place the measuring rod perpendicular to the measuring surface, and the measure the depth distance.

Vernier caliper reading method:

- Step 1: Find the zero position first by putting the two outer measuring surfaces of the vernier caliper close to each other, and align the zero-scale line of the ruler with that of the vernier scale.

- Step 2: Read the scale value of the main ruler first.

- Step 3: Look at the overlapping scales of the secondary ruler and the main ruler.

- Step 4: Add the values of the main ruler and the secondary ruler to get the value of the measurement result.

Precautions for using vernier calipers:

- Before using the caliper, use a clean soft cloth to gently wipe the sliding surface and the measuring surface, to wipe off dust or dirt before use. Clean the outer measuring claw with cloth or tissue paper.

- For digital calipers, after replacing the battery, use the "ORIGIN" key to set the origin.

- Scratching the main ruler of the digital caliper, or writing on it with an electric pen, will cause interference to the electrical components and cause malfunction.

- Take care to prevent dropping or striking the calipers.

- Since the tip of the caliper is very sharp, use with care to avoid injury during operation.

- When measuring with the root or tip of the claw of a caliper, be especially careful to not apply too much force as this can cause errors in the reading.

- After use, wipe off any water or oil and apply a layer of anti-rust oil before storing. The body of the waterproof caliper may be prone to rust, so be sure to wipe it clean of water.

- Take care to avoid direct sunlight, high temperature, low temperature, and storage in a high humidity environment.

.jpg)

.png)