Nowadays, products have many functions and high complexity, so the requirements for the quality and precision of molds are becoming more and more stringent. Only through a complete evaluation and testing in the early mold development process can we produce mold products that customers are satisfied with.

In the process of mold making, the focus is accurate to size and punctual mold trial. If the premise is not carefully evaluated and tested, subsequent mold production will be doomed to fail. At present, there are more and more requirements for mold making, because the function of the product has increased and the complexity has also increased, making it more and more difficult to make relative molds. But on the contrary, the time required for mold making is shortened, which is also a challenge faced by the mold industry.

Mold-making itself is a technology-intensive and high-level industry. It cannot be fully automated and produced according to the production line, and there is a lack of a perfect mold production management model. If the industry needs to be upgraded, the most effective way is to divide the labor and cooperate with each department to specialize, and have an overall process planning. In-mold manufacturing, the best management is the smoothness of the mold processing process. The processing process is very flexible. There is no fixed rule, and there is no constant rule. We can only make full use of the existing equipment, manpower, and resources of the factory. Get maximum profit with minimum cost.

How do Arrange the Mold-making Process?

A good production unit with an independent division of labor and cooperation among various departments must have a complete and smooth production management process to coordinate the contact of various departments and allocate processing time for each department to complete the complete production of a pair of molds. How to arrange a good mold-making process, and how to control the entire project progress according to the processing schedule.

How to arrange a good schedule, the preparatory work before mold making is extremely important. Before arranging the schedule, communicate with the customer and understand the customer's requirements to make the mold that meets the customer's requirements. The communication between the two parties must be fully communicated. Work, especially the key points specified by the customer, such as biting, sandblasting, replacing the sub-type, heat treatment or not, the requirements of the appearance and polishing level, as well as the limitation of important dimensional tolerances, the reservation of the matching parts, etc., each small details are greatly related to the schedule, so we cannot neglect or ignore any small details. A little negligence or neglect will affect the delivery time and affect the quality of the mold. Therefore, communication and coordination with the customer's technology is the first step to making a good mold. step. The next step is to have a complete mold design. Design is the soul of modern mold-making. The design must be matched with on-site processing to meet customer requirements. It goes well, so the production schedule is arranged, in addition to the on-site department supervisors and mold makers, it must be jointly arranged with the design department, and the processing sequence is correctly arranged from the design drawing within the predetermined production time, and the processing progress is listed one by one in added to the schedule.

What is the Mold Development Technologies?

- Mold design: Establish mold design specifications to achieve high quality, low cost, and short-term production and development goals.

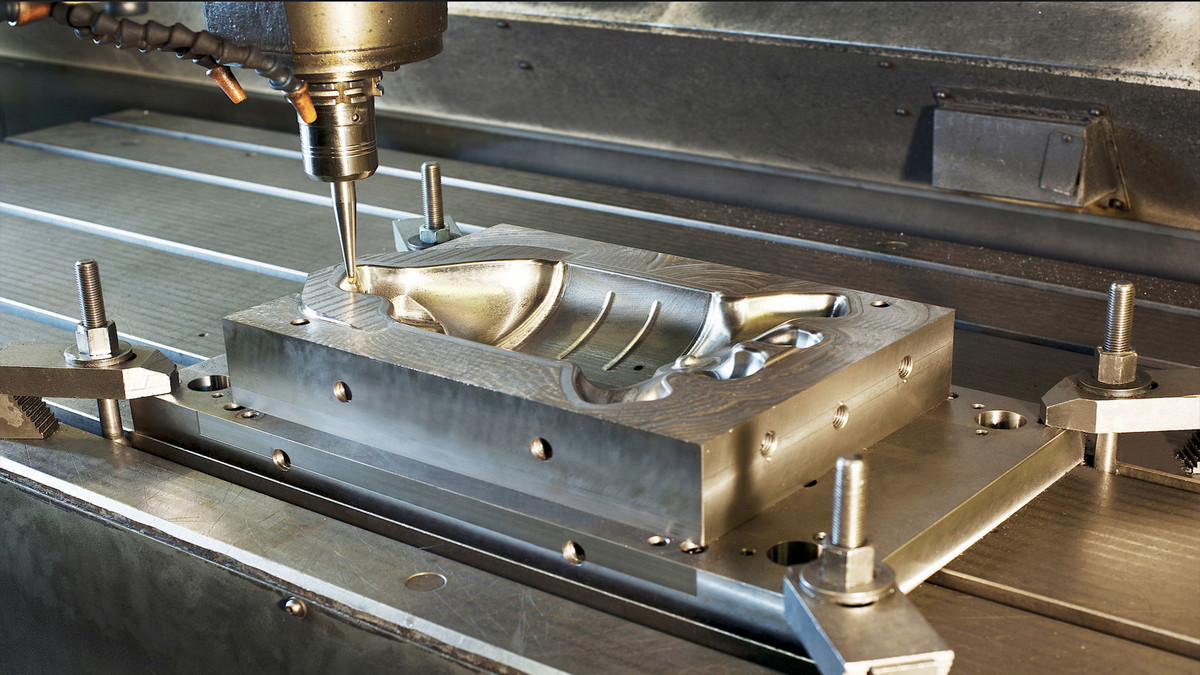

- Mold processing: Have a variety of precision mold processing equipment and strong support from excellent manufacturers to establish a complete mold manufacturing process.

- Mold measurement: To ensure the accuracy of the mold, use measuring instruments such as height gauges, measuring instruments, vernier calipers, plungers, etc.

- Mold assembly: The mold assembly standard is established by the senior mold engineer, and the method standard is consistent.

What is the Mold Development Process?

- Appraisal: Provide relevant requirements such as samples/ real products or design drawings (2D 3D drawings), and give appropriate quotations and estimates.

- Meeting: Discuss the related requirements of production molds and solve related problems.

- Quantity of product demand and frequency of production.

- Scope of application.

- Product appearance requirements.

- Inspection dimensional standards.

- Functionality.

- Mold material requirements.

- Product material requirements.

- Design: Establish mold design specifications to achieve high quality, low cost, and short-term production and development goals.

- Analysis of product feasibility.

- Arrange the process of the product, determine the content of the process, and implement it using the design software.

- Prepare materials according to the product unfolding drawing and confirm its relevant dimensions.

- Mold map drawing.

- Proofreading.

- Plan: Make a production plan, prepare, allocate, and use the raw materials, personnel, and equipment exactly. By the ISO9001 process management procedure, the standardization of the manufacturing process is established, the stable process is established, and the on-site management is improved to ensure the timeliness of product delivery and the stability of quality, and effectively manufacture products that meet customer requirements.

- Preparation/ Drawing completed: The mold material preparation and mold design drawing are completed.

Design the 3D image into a plastic mold surface, and conduct a preliminary mold flow analysis.

- With or without barbs: The barbs affect the quality of the finished product in the mass production stage. If the design evaluation is wrong in the modeling stage, it may lead to the failure of demolding. In the worst case, the entire set of molds will be scrapped and cannot be used.

- Whether the demolding angle is sufficient: Pay attention to whether the de-molding angle is sufficient, because friction will generate resistance during demolding, and the angle may be insufficient, the mold may not be able to fall off, or there may be a large amount of mold difference when falling off, causing side scratches on the part. If the small details are not accurately grasped, the serious situation will even slow down the production cycle of the entire product.

- In-point selection: In-point selection will affect the surface of the product, bond lines, and smoothness of final product production.

- Selection of cold and hot runners: Cold runners will produce runners, and the longer the runners, the greater the sheer heat. Reducing the filling effect of the finished product will also extend the required shear channel, but the cost is relatively low. After the hot runner is injected, the plastic in the runner does not solidify, and it is not necessary to remove the waste in the runner when the plastic product is demolded, but the hot runner system is relatively expensive.

- Mold material: It is determined according to the product plastic and product quantity. The mold material affects the life of the mold. The better the material, the longer the life of the mold.

The 3D mold is then converted into a 2D machining drawing. Arrange related procedures and schedules for the split machining drawings.

- Graphical requirements: Must be drawn to scale, allowing for enlargement or reduction. The view selection is reasonable, the projection is correct, and the layout is appropriate. To make the processing patent number easy to understand and easy to assemble, the graphics should be as consistent as possible with the general assembly drawing, and the graphics should be clear.

- The dimensioning requirements are unified, centralized, orderly, and complete. The order of dimensions is as follows: Firstly, mark the size of the main parts and the draft slope, then mark the matching size, and then mark all the dimensions. On the non-main parts drawing, first, mark the mating dimensions, and then mark all the dimensions.

- Surface roughness: Mark the most widely used roughness on the drawing, and mark the roughness symbol on each surface of the part.

- Other contents: Such as part name, mold drawing number, material grade, heat treatment, hardness requirements, surface treatment, graphic scale, the machining accuracy of free size, technical description, etc. must be filled in correctly.

- Machining/ Matched molds: Process and manufacture according to the production plan, including mold base machining, CNC machining, electrical discharge machining/electrode machining, wire cutting, fitter, grinding/drilling, and the mold assembly. Use a variety of processing machines for die base machining and die core parts manufacturing.

After completing the development of the mold base and mold core, assemble the male and female molds, and reconfirm whether there are tolerances that need to be corrected.

- Try shoot/ Mold changes:

- Preparation before mold trial: Preparation of related accessories, vernier calipers, and dimension drawings.

- Attention during mold test: Problems related to finished products such as top white, top convex, shrinkage, lack of material, etc. Shrinkage test, according to material test. Mold switch mold smoothness test.

- Inspection of injection problems: Establish problem improvement policies and conduct assembly tests.

- Check: Check the size, color, and related conditions of plastic injection products to ensure product quality. Discuss the test results of the finished product with the customer, and carry out processing options such as mold polishing, biting, and heat treatment according to the customer's requirements.

- Complete: Confirm the weight of the mold and formulate the mold history for inquiry. Production according to customer demand, usually in small batches for the first production.

- Produce/ Delivery: To produce after the mold is completed: mass production according to the injection molding process. For delivery, make sure that there is no damage to the appearance of the mold before packaging, the mold will be stacked on the pallet by the warehouse staff, and wait for delivery after completion.

How to move from tradition to modernization, from technology-intensive to technical unit specialization and production, and from the overall mold making, division of labor to various machining departments, specializing in parts processing, and then combining various departments to form a whole set of molds, this is a transformation in the form of mold processing, an improvement in the technical level, and an upgrade in the automation of the mold industry.

.jpg)

.png)