Under the influence of the China-US trade war and COVID-19, the border management of various countries is still very strict, and global economic and trade activities have not been thawed, which has caused the price of some raw materials to rise. Therefore, if machine tools can be designed with a lightweight structure, it will reduce manufacturing costs and increase profits. Lightweight moving castings can also improve the dynamic characteristics, which will be of considerable help to high-speed or high-precision machine control.

What Is Topology Optimization?

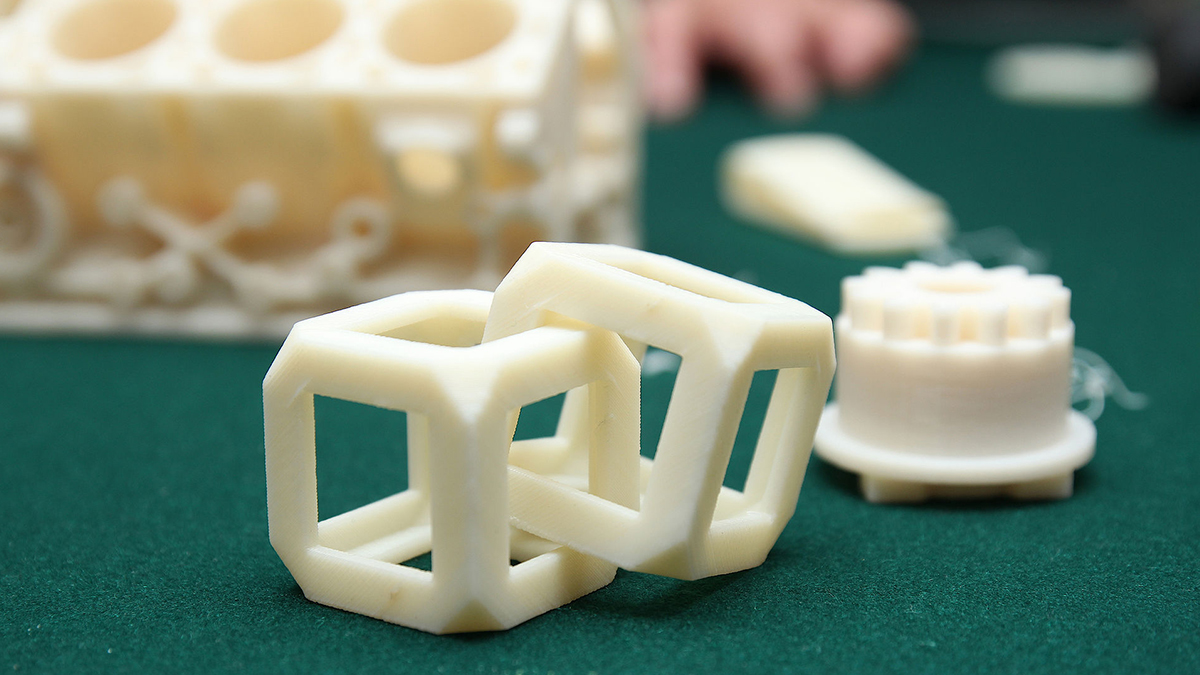

Topology optimization is a mathematical method that can optimize the material layout in each design space for a set of given loads, boundary conditions, and constraints, and let the design meet the given conditions (loads, boundary conditions, constraints) for the optimized performances. The difference between topology optimization and shape optimization or size optimization is that the design can obtain any shape in the design space. Usually, topological optimization will use the finite element method to evaluate the design performance.

Machine tool terminal applications can be roughly divided into rough machining processes with high removal volume and finishing processes requiring precision and surface finishing. The essence of the machine is an electro-mechanical, integrated system, including machine structure and servo drive control modules. Therefore, to simulate the dynamic characteristics of the machine by CAE analysis technology, it is necessary to integrate the machine structure and the servo drive control module, to construct a complete electro-mechanical, integrated multi-body dynamic, digital model. The correctness of each subsystem model is guaranteed. It will affect the results of the dynamic simulation analysis of the whole machine.

In recent years, although the machine tool industry has gradually introduced CAE computer simulation analysis technology for machine development, most of these technologies are still based on static rigidity analysis and modal analysis. The analysis results are not yet sufficient to directly match the cutting efficiency and cutting accuracy that machining users want. The cutting accuracy or machine development processing efficiency often does not meet the customer's expectations, or the mold surface processing lines are abnormal. At the initial stage of development, the machine and equipment will have application conditions linked to the design process. The clearer the requirements and more precise the design, the quicker topology optimization technology can be integrated to modify the structure.

Topology optimization design technology of electro-mechanical integrated structure

With structural topology optimization technology, combined with electro-mechanical integration technology, if the rigidity of the casting is defined as the topological optimization target, and the dynamic error demand is used to reverse the moving casting weight as the topological optimization constraint, the tool that best meets the design target requirements can be automatically solved. The machine structure design can not only meet the light weight requirements, but also eliminate the need for multiple modifications in the casting design. Final precision cutting requirements can be met and high-efficiency structural optimization can be achieved, effectively reducing the influence of human subjective factors, and greatly improving the design development efficiency.

At present, most structural topology optimization technologies are aimed at static rigidity or modal frequency. More advanced methods can also be used to optimize the structure of the frequency response function FRF amplitude, but this optimization result is only required for a high cutting removal rate. The terminal application can predict the cutting depth under the processing requirements. There is no clear index for the finishing surface texture requirements. This often results in abnormalities in the mold surface processing lines after the machine development is completed. The dynamic error performance of the machine is comparable to the precision of the machine, which will be reflected in the quality of the processed surface texture. The integration of structural topology optimization technology with electro-mechanical simulation technology enables the construction of electro-mechanical, structure topology optimization. The user defines the dynamic error required under empty running machine acceleration. The mathematical relationship between the weight of the moving casting and the dynamic error can be deduced as the topology optimization. The optimization of this structure is directly related to the end cutting accuracy, which can greatly improve the development efficiency.

The machine tool can be set to different configurations to meet different industrial application scenarios. The frequency response function FRF is a very important quantitative indicator of the machine. For the rough machining process, processing efficiency is the main consideration. The frequency response function FRF can be integrated into the calculation model of the cutting chatter steady-state graph to evaluate the cutting efficiency. For the finishing process, the machining accuracy is the main consideration, and the dynamic error performance of the machine is related to the quality of the finishing surface texture. If the dynamic error of the empty running track of the machine structure can be effectively reduced in the design, the machining accuracy will be better in the real machine fine cutting.

Mechanical and electrical integration analysis technology can effectively predict the dynamic error of the machine, and the dynamic error performance of the machine is related to the inertia (mass) of the moving casting of each axis. The user defines the dynamic error of machine acceleration during empty running, and the weight of the moving casting can be determined. The dynamic error is used as the limiting condition of topology optimization, and the optimization result of this structure is directly related to the final cutting accuracy.

Topology optimization design technology SOP and benefits of electro-mechanical integrated structure

The standard operating process of the mechanical and electrical integration structure topology optimization design technology: The user defines the dynamic error of the required machine under empty running acceleration. The special module of the mechanical and electrical integration of the machine tool and can reverse the mathematical relationship between the dynamic error of the moving casting and the weight curve. Using the aforementioned relational expression as the limiting condition of topology optimization, the optimization result of this structure can directly meet the designer's dynamic error requirements. Compared with traditional topology optimization technology, it is not necessary to integrate the mechanical and electrical integration technology to determine the dynamic error performance at the initial design stage. By modifying the casting design at the development end, you can confirm whether the path error generated after the machine and the servo control match the customer's accuracy requirements. The electronically controlled machine processes are also in the development stage. With the integration of different servo control parameters and structures, you can quickly integrate mechanisms, electric controls, and processes into the initial stage of machine development to improve machine tools development efficiency. The overall change of design technology will lead to a qualitatively changed, high-quality machine tool design process.

.png)