Knowledge

A tape measure is a common measuring tool designed for measuring great lengths, yet compact enough to be easily carried in a pocket or toolkit. The typical tape measure consists of a long strip of metal, fiberglass, or cloth encased in a durable plastic or metal housing. The tape is marked with measurements, usually in both inches and feet, as well as centimeters and meters, allowing for measurements in both the imperial and metric systems. Most feature a locking mechanism to ensure the tape stays extended while measuring. With a simple press of a button, a spring mechanism inside the housing smoothly retracts the tape for storage after use.

2024-12-24 10:13:32

Wrenches, commonly referred to as such in North America, or spanners, the standard term in the UK, Australia, or New Zealand, are tools used to apply torque for turning objects like nuts and bolts, pipe fittings, and other fasteners or components. They serve a wide range of applications, from everyday tasks like household repairs to industrial manufacturing, where they form the backbone of assembly lines, ensuring the precise fitting of components. Auto repair professionals rely on wrenches for tasks ranging from routine maintenance to complex engine overhauls. The early predecessors of the wrench were simple hand-forged devices. However, as the need for precision and efficiency grew, wrenches evolved into the sophisticated tools we know today. It was during the Industrial Revolution that wrenches took on new forms, with the advent of adjustable wrenches and the proliferation of standardized nuts and bolts.

2024-12-24 10:08:58

Weather for household repairs, such as fixing a leaky faucet, tightening loose screws, or bending wires, or in industrial manufacturing, assembly lines, or construction fabrication processes, the design and precision of a good pair of pliers makes them ideal for gripping, bending, and cutting materials with precise control. Specially designed pliers, such as needle-nose and locking pliers, allow electricians or auto repair professionals to access confined spaces and exert precise force when needed.

2024-12-24 10:02:56

A hammer is one of the most commonly used hand tools. Around the home, if something isn’t working, just give it a few whacks with a hammer and that will take care of it! Kidding aside, the hammer is the most often used hand tool, as it can be used to do multiple jobs around the house like assembling and repairing furniture, driving nails to hang pictures and artwork, or in the garden for securing stakes plants or assembling small structures, etc. Professionals such as carpenters and construction workers depend on hammers to do various tasks like framing, nailing, and assembling wooden structures, roofing, and general building. Blacksmiths use hammers to shape and forge hot metal into desired forms. Masons use hammers for tasks like chiseling, breaking stones, and setting bricks or blocks in place. Auto mechanic and metalworker use hammers for tasks like shaping metal, removing dents, or disassembling parts. And the list goes on.

2024-12-24 09:58:35

Whether you're assembling a self-assembly bookshelf or working on an assembly line, the screwdriver is the go-to tool. Its simple yet effective design, consisting of a handle and a tough steel shaft, makes it indispensable for a myriad of tasks.

2024-12-24 09:52:43

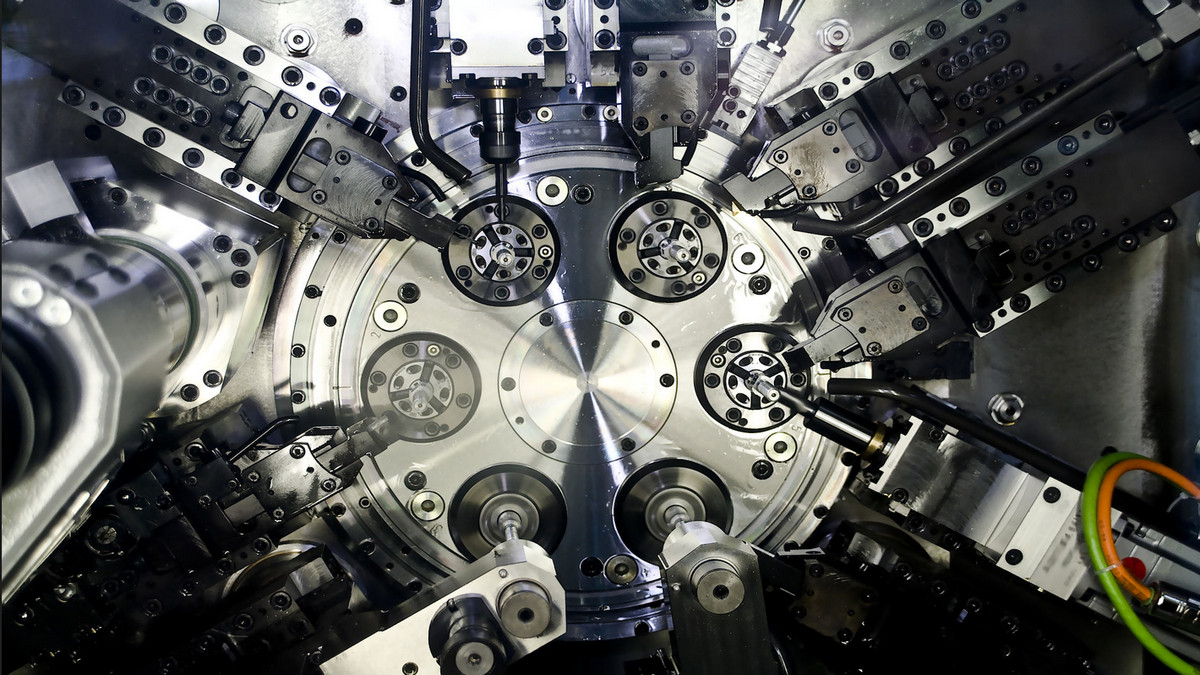

Rotary Indexing Plates are precision components of milling machines that facilitate the precise angular positioning of workpieces and cutting tools. They are used in both metal machining and woodworking, and while they share a fundamental purpose, there are notable differences in their design, capabilities, and applications due to the distinct characteristics of the materials and processes involved.

2024-11-18 15:19:30

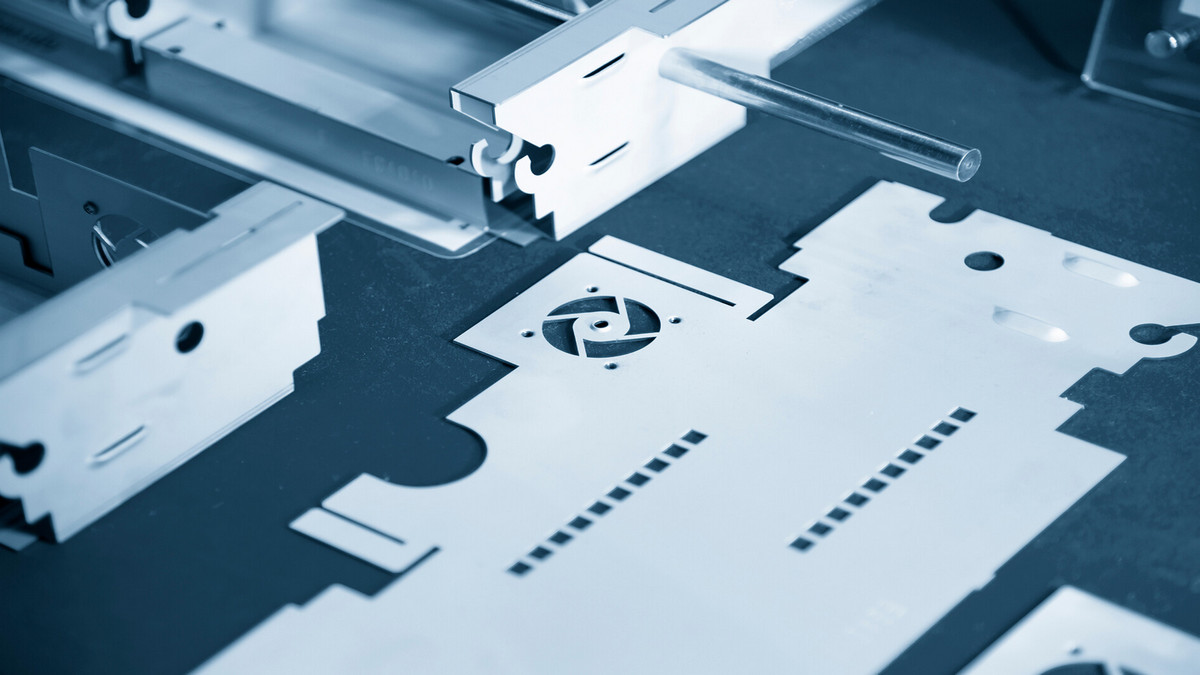

Sheet metal machines are widely used in various manufacturing industries for shaping, cutting, and forming sheet metal into different components. Some of the industries that extensively utilize sheet metal machines include light industries such as electrical and medical equipment, all the way up to heavy industries such as automotive, rail, oil and gas, as well as wind power generation.

2024-11-18 15:00:35

Metal and wood planing machines are essential tools in the machining industry. Wood planers use a rotating cutterhead equipped with sharp blades to smooth and size workpieces, ensuring uniformity in woodworking projects. Metal planers use a cutting tool mounted on a reciprocating tool head to remove excess material from metal surfaces, achieving precise dimensions in components. Both types of planning machines enhance efficiency, precision, and the overall quality of finished products. Understanding the key features of the various types of planing machines will help you choose the right machine best suited for your machining needs.

2024-11-18 14:45:43

Nestled in the heart of East Asia, Taiwan has emerged as a powerhouse in the global stamp press industry, with a robust manufacturing ecosystem, and cutting-edge technology. With a rich manufacturing tradition and a focus on precision engineering, Taiwanese companies meet the demands of diverse sectors, ranging from electronics and automotive to medical devices and aerospace, supplying high-quality stamp press solutions to a diverse range of markets worldwide.

2024-11-18 14:14:16

Stamp press technology, also known as stamping or pressing, is a manufacturing process that utilizes a press to shape or cut materials into desired forms. This process involves the use of a die and a punch to form or cut the material, creating intricate shapes with high precision. Widely employed for mass production due to its speed, accuracy, and repeatability, this process is a crucial part of modern manufacturing.

2024-11-18 12:07:43

Hot Topic

Agree