Cutting technology has many different processing techniques, and laser cutting can perform more complex and precise cutting requirements, which is also a common processing technique in industrial manufacturing.

You have heard of the laser engraving machine, so do you know what the laser engraving machine is used for? Laser engraving is to eliminate a part of the material during the operation of the equipment, causing the surface of the material to show the image, so that the material is left on the material. It becomes an engraved mark. The laser light acts like a chisel and blows away selected areas of the material, the depth of the engraving varies according to the set parameters. Different laser engraving machine equipment has relatively suitable materials. Next, let this article take you to understand the application methods and uses of laser engraving in different industries, so that you can better understand the laser engraving machine.

Application of Laser Engraving in Different Industries

Laser Cutting Machine- Textile and leather industry: For thick textile and leather fabrics, such as denim, can be laser engraved with patterns or logos.

- Printing industry: It is often used for engraving and embossing of special paper materials. Even complex graphics can be mass-produced quickly.

- Watches and Jewelry Industry: Laser beams can be controlled very precisely and can be used for marking and processing of clocks, watches, and jewelry.

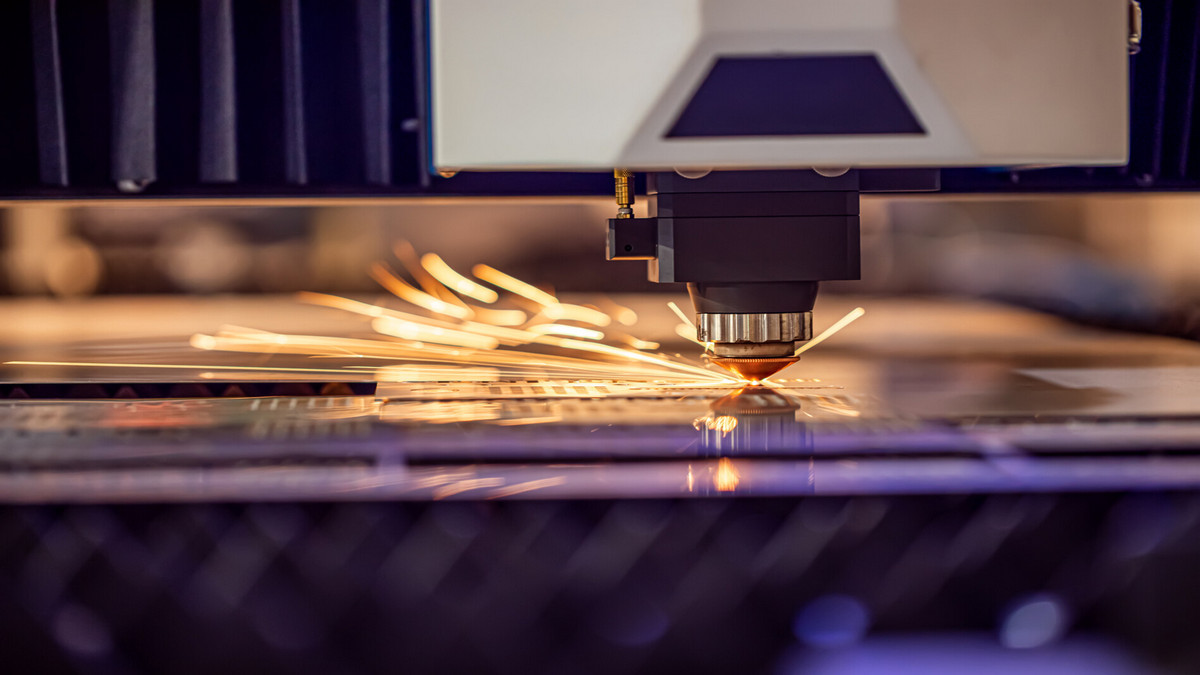

- Sheet metal industry: Metal materials such as iron, copper, stainless steel, and aluminum can be cut with a high-power optical fiber system.

- Advertising and art industry: All kinds of surrounding life signs, gifts, handicrafts, advertising signs and gifts industry, and even the lighting industry are quite dependent on laser engraving processing technology.

Laser Marking Machine- Hardware and electronics industry: Precision marking in the hardware and electronics industry, including kitchen utensils, electrical appliances, hardware, plastics, molds, etc. metal laser marking machine can be used.

- Metal sheet industry: Metal materials such as iron, copper, stainless steel, aluminum and other metal materials can be engraved with metal marking machines. The high-energy laser is focused on the surface of metal products to instantly vaporize the surface material, leaving permanent traces.

- Advertising and art industry: All kinds of surrounding life signs, gifts, handicrafts are widely used, which is more convenient and environmentally friendly than traditional screen printing.

What are the 12 Main Uses of Laser Engraving Machine Across Industries?

The laser beam generates high heat during the engraving process, evaporating the material, and if a deeper image mark is required, it can be repeated several times to make the depth more pronounced. The use of laser engraving machines is beyond your imagination. In fact, you can see laser engraving applications everywhere in your life. The following are 12 common laser engraving uses for you to easily understand.

- Advertising sign industry: Make various badges, signs, various house numbers, signs, etc.

- Model making industry: Making architectural models, house models, etc.

- Footwear industry: Identify leather trademarks, logos, etc.

- Jewelry industry: Finely carved jewelry, carved ornaments.

- Wood industry: Used for the design and production of carved patterns.

- Advertising and gifts industry: Used to engrave all kinds of two-color plate signs, plexiglass, Vatican stone houses, three-dimensional signs, decorative gifts, light box two-color statues, various medals and trophies, and organic plate embossed three-dimensional patterns.

- Automobile industry: Tire mold lamp mold and decorative mold processing.

- Tobacco industry: Used for anti-counterfeiting signs of cigarette packs, template making and cigarette manufacturing.

- Mold industry: Engraving button embossing mold, injection mold, blow mold, stamping mold, glasses mold, etc.

- Optical industry: Camera aperture zoom components and scale processing.

- Packaging industry: Carton, packaging plastic, mold making.

- Printing industry: Used for embossing, embossing and carving.

.png)