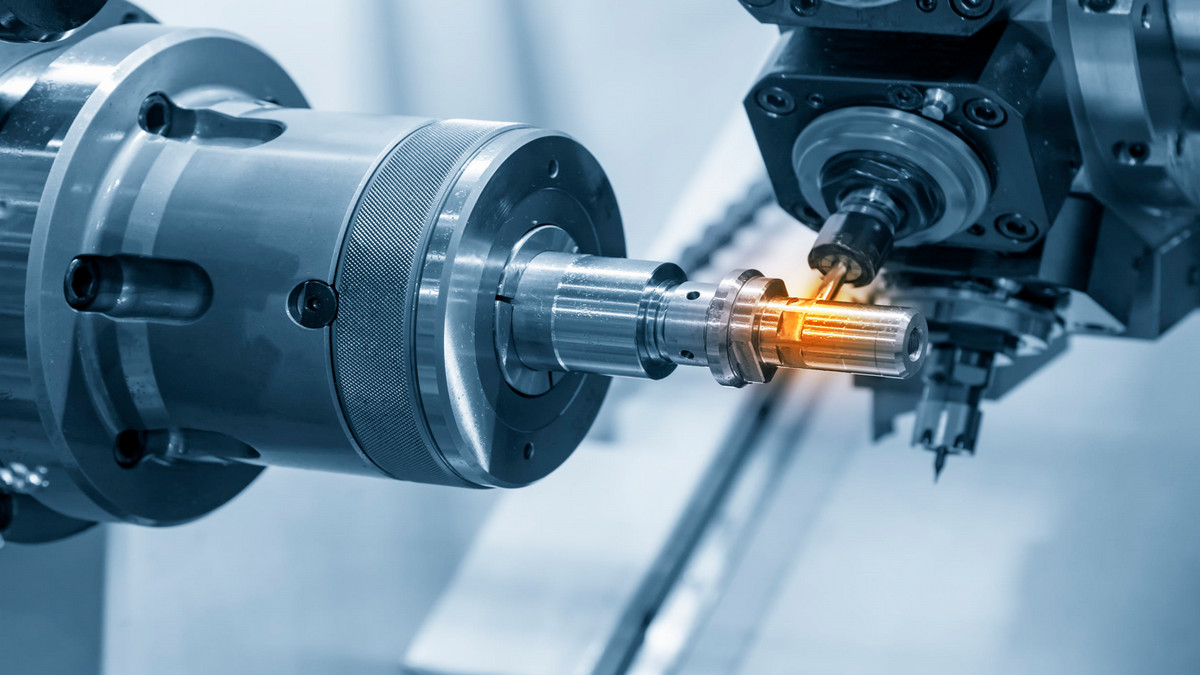

The thread is usually the last feature added to the part. There are other challenges besides the exact parameters required and standard threading issues.

Introduction to Deep Hole Threading

The thread is usually the last feature added to the part. Therefore, the part usually takes a lot of manufacturing time, and if there is a problem, the cost of scrapping or rework is very high. It is important to understand the exact parameters required to generate the required threads. Applications that require deep-hole threads face other challenges besides standard threading issues.

But what is considered a deep hole thread? Experts agree that any thread depth that exceeds the normal standard is considered a deep hole for threading and is often greater than 3xD. Most manufacturers make standard tools with 1x, 2x, and 3xD resolutions, while deeper applications require custom tools.

Threading method and hole type

For deep hole threads, through holes or blind holes present different challenges, especially depending on the type of threading method used, whether it is tapping, thread milling, or thread forming. The choice between these methods is highly dependent on various factors. In most cases, thread milling is preferred in deep hole threading, especially in hard materials.

How to Perform Deep Hole Threading?

First, we need to define what a deep hole is and why it needs special consideration. In drilling, those holes with a depth greater than 3 times the hole diameter are called deep holes. Deep hole tapping means that the tapping depth is more than 1.5 times the diameter of the tap. For example, when a tap with a diameter of 1/4" is used to machine a thread with a depth of 3/8", this situation is usually called deep hole tapping.

Machining a deep hole thread means that it takes a long time to contact the tool and the workpiece. At the same time, more cutting heat and greater cutting force will be generated during the machining process. Therefore, tapping in small deep holes of special materials (such as titanium parts) is prone to tool breakage and thread inconsistency.

To solve this problem, two solutions can be adopted: (1) Increase the diameter of the hole before tapping; (2) Use a tap designed for deep hole tapping.

-

Increase the diameter of the hole before tapping

A suitable threaded bottom hole is very important for thread processing. A slightly larger threaded bottom hole can effectively reduce the cutting heat and cutting force generated during the tapping process. But it will also reduce the contact rate of the thread.

The National Standards and Technical Committee stipulates that in deep holes, only 50% of the full height of the thread is allowed to be tapped on the hole wall. This is especially important when tapping small holes in special materials and difficult-to-process materials. Because although the thread contact rate decreases due to the decrease of the thread height on the hole wall, the thread length increases, so the reliable connection of the thread can still be maintained.

The diameter increment of the threaded bottom hole mainly depends on the required thread contact rate and the number of thread heads per inch. Based on the above two values, the correct threaded bottom hole diameter can be calculated using empirical formulas.

-

Cutting parameters

As titanium parts are difficult to machine, it is necessary to fully consider the cutting parameters and tool geometry.

- Cutting speed: Due to the large elasticity and deformation rate of titanium alloy, a relatively small cutting speed is required. When machining small holes in titanium alloy parts, the recommended circumferential cutting speed is 10-14 inches/min. We do not recommend using a lower speed, because that will lead to work hardening of the workpiece. Also, pay attention to cutting heat caused by tool breakage.

- Chip pockets: When deep hole tapping, it is necessary to reduce the number of tap flutes to increase the chip space of each flute. In this way, when the tap is retracted, more iron filings can be taken away, reducing the chance of tool damage due to the blockage of iron filings. But on the other hand, the enlargement of the chip flute of the tap reduces the core diameter, so the strength of the tap is affected. So, this will also affect the cutting speed. Besides, spiral flute taps are easier to remove chips than straight flute taps.

- Rake angle and relief angle: A small rake angle can increase the strength of the cutting edge, thereby increasing tool life; while a large rake angle is conducive to cutting metal with long chips. Therefore, when processing titanium alloys, these two factors must be considered comprehensively, and a suitable rake angle should be selected.

The large clearance angle can reduce the friction between the tool and the chips. Therefore, sometimes the tapping angle is required to be 40°. When processing titanium metal, a large clearance angle is ground on the tap, which is conducive to chip removal. Also, the fully ground taps and the back-ground taps are conducive to tapping.

- Coolant: When processing special materials, you must ensure that the cutting fluid reaches the cutting edge. To improve the flow of coolant, it is recommended to open a cooling groove on the back of the tap. If the diameter is large enough, an internal cooling tap can be considered.

.png)