Electric discharge machining is a kind of special machining technology, which is widely used in mold manufacturing and machining industries. Electrical discharge machining can be used to machine superhard materials and workpieces with complex shapes that are difficult to machine with traditional cutting methods. It is usually used to machine materials that conduct electricity. It can machine complex materials such as titanium alloys, tool steels, carbon steels, and hard alloys. cavities or contours.

Technical Principle

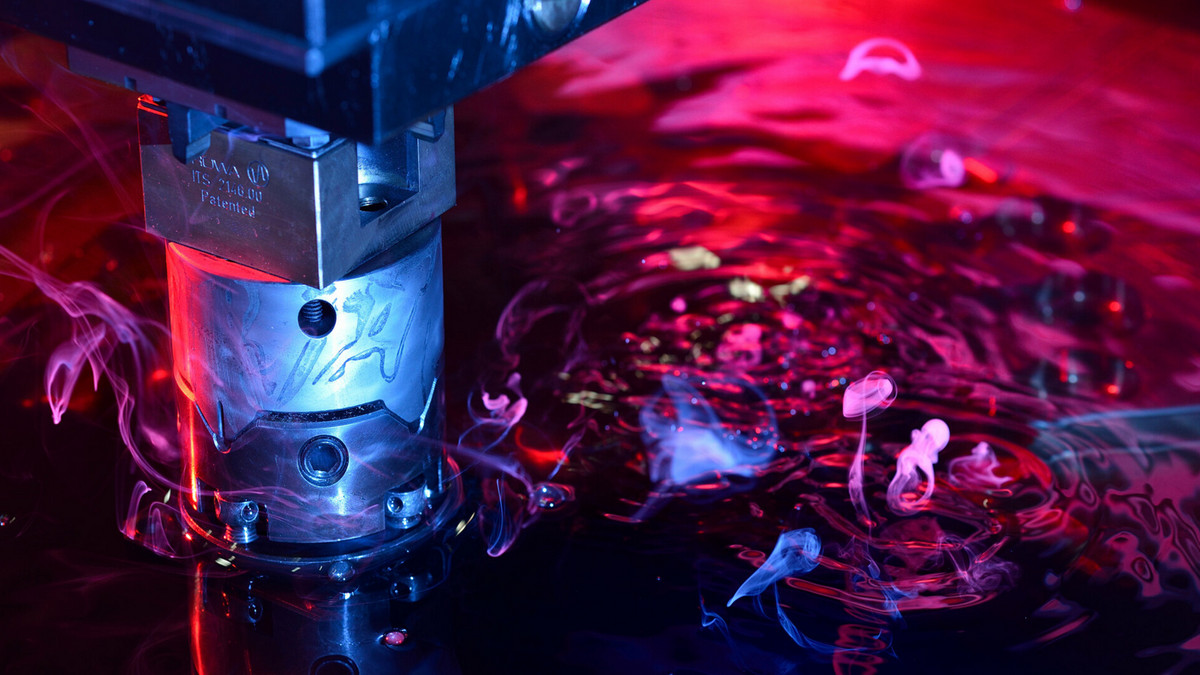

A special processing method for removing conductive materials by using the electro-erosion effect generated by the pulse discharge between the two poles immersed in the working fluid. We all have such life experience. After a period of use of electrical switches, the surface of the contact part is often eroded by electric sparks, which is rough and uneven. This is the phenomenon of electric spark erosion. EDM is to use this principle, in a certain medium, through the electrical erosion of the pulse discharge between the tool electrode and the workpiece electrode, the method of processing the workpiece. The basic way to achieve this processing is as follows: The tool electrode and the workpiece are all immersed in the working medium (electrolyte), multiple spark discharges are generated between the two electrodes, and the amount of workpiece erosion is consciously controlled. The workpiece meets certain size and roughness requirements.

The principle of electric spark erosion for metal processing must also meet the following conditions: the spark discharge energy must be large to ensure local melting and gasification of the metal in an instant; the discharge form should be a very short pulse discharge, so that the spark heat is too fast to transfer to the non-processing area to prevent the phenomenon of "burning"; after each pulse discharge, the metal particles and ionized substances generated between the electrode gaps must be discharged from the gap in time to ensure the continuous processing.

Physical Process

The physical process of electrode corrosion by electric spark is very complex, and it is a process of combined action of electromagnetism, thermodynamics and fluid mechanics, and people have not yet had a comprehensive understanding of it. It is generally considered that it can be divided into three stages: the first stage forms the discharge channel, in which the electrolyte is ionized, broken down, and forms a discharge channel; the second stage forms an energy conversion on the surface of the workpiece, that is, spark discharge, generates thermal expansion, and makes the tool electrode and workpiece are etched away; the ablation from stage 3 is thrown out of the discharge gap in preparation for the next discharge.

Processing Features

- It can process any hard, brittle, tough, soft, high-melting conductive materials, and under certain conditions, it can also process semiconductor materials and non-conductive materials.

- "No cutting force" during processing, which is beneficial to the processing of small holes, thin walls, narrow grooves, and various complex shapes of holes, spiral holes, cavities and other workpieces, and is also suitable for precision and micro machining.

- When the pulse width is small, the whole workpiece is hardly affected by heat, so the heat-affected layer can be reduced, the surface quality after processing can be improved, and it is also suitable for processing heat-sensitive materials.

- The pulse parameters can be adjusted arbitrarily, and roughing, semi-finishing and finishing can be continuously performed on one machine tool. The precision of finishing is 0.01mm, the surface roughness Rα value is 0.8μm; the precision of fine machining can reach 0.002~0.004mm, and the surface roughness Rα value is 0.1~0.05μm.

- Direct use of electrical energy processing, easy to achieve automation.

Actual Application

Due to the high discharge energy during electric discharge machining, it can process materials that cannot be machined by ordinary cutting methods, such as hardened steel, heat-resistant alloys, and cemented carbides. At the same time, it has been widely used in the field of processing various complex cavities, dies and holes. Since there is no direct contact between the tool electrode and the workpiece during the EDM process, the cutting force is very small, which is very effective for machining those easily deformed workpieces and small and precise holes and narrow slits. Now the EDM process has been widely applied in various sectors of the industry, and it is a very promising processing method.

In the current machining field, especially in precision machining, electrical discharge machining has been widely applied. The range of electrical discharge machining is as follows:

- All conductive materials can be processed by electrical discharge machining.

- The highest precision of electric discharge machining can reach +/- 0.005mm, and the surface roughness can reach the highest mirror surface.

- Stations that cannot be processed by traditional machining can generally be completed by electrical discharge machining.

- The discharge station can be the cavity of various large-scale plastic molds, or it can be a small hole with a width of 0.1MM, a small groove, etc.

Advantages and Disadvantages

Advantages of EDM:

- It can manufacture odd-shaped surfaces that cannot be produced by traditional cutting machines.

- Machining hard materials can also have good tolerance accuracy.

- The cutting force of traditional machining machines may damage small workpieces, but EDM does not.

Disadvantages of EDM:

- Non-conductors cannot be processed (technologies already exist to process ceramic materials).

- The processing speed is slow.

- The processing cost is high.

.png)