- Showing results for

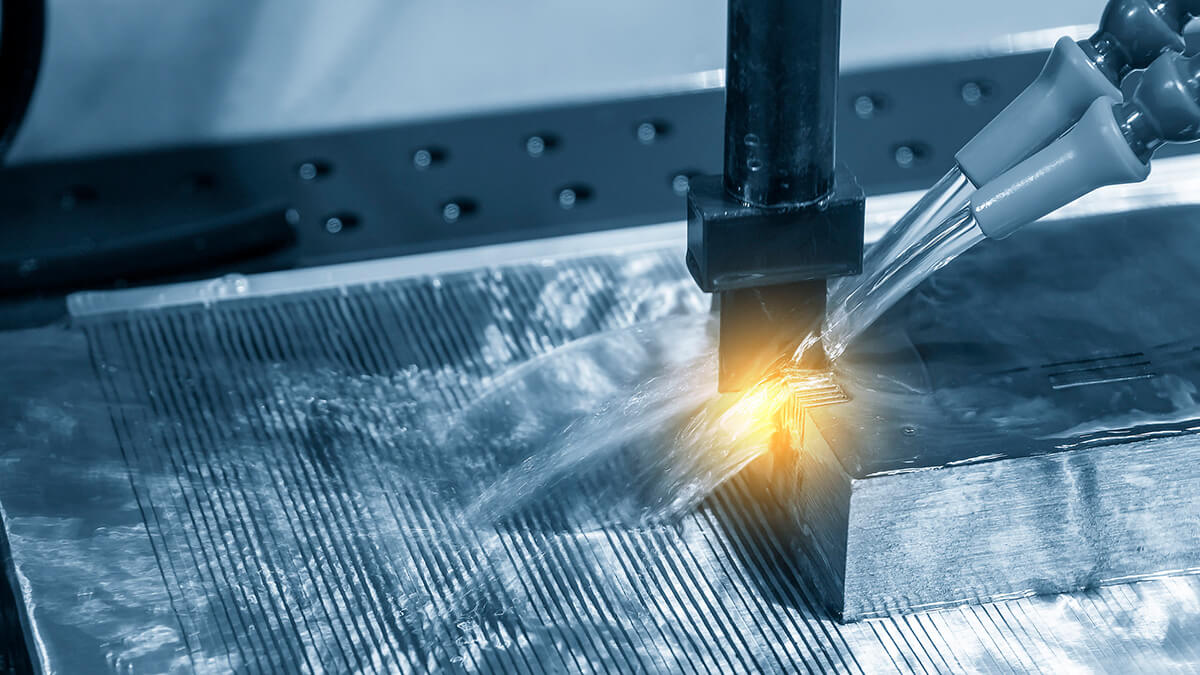

- Wire Cutting EDM

There are some differences between the general EDM machine and wire-cut electrical discharge machining. Different processing technologies are applied to different industrial manufacturing needs.

2020-03-23 10:40:02

Before getting to know EDM machine, start with understanding the type of EDM machine, including wire EDM, sinker EDM, and hole drilling EDM, and perform metal cutting through electrical discharge machining.

2020-03-23 13:17:24

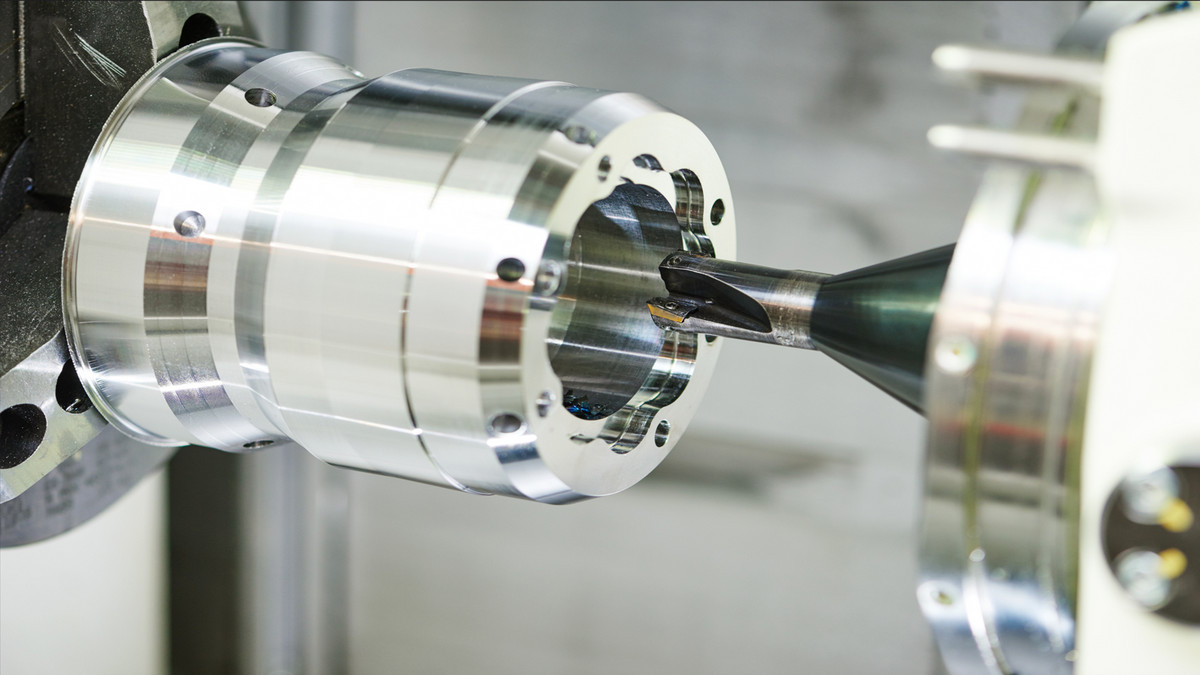

When selecting a milling cutter suitable for the machining task, various issues such as the geometry, size, and work piece material of the parts to be processed must be considered.

2020-06-29 13:23:59

There are some differences between the general EDM machine and wire-cut electrical discharge machining. Different processing technologies are applied to different industrial manufacturing needs.

2023-05-04 13:26:24

Industrial manufacturing requires machining tolerances. EDM machine can cut metal through electric current.

2023-07-28 11:20:03

Agree