Before getting to know EDM machine, start with understanding the type of EDM machine, including wire EDM, sinker EDM, and hole drilling EDM, and perform metal cutting through electrical discharge machining.

EDM can be divided into three common types: wire EDM, sinker EDM, and hole drilling EDM.

Wire Cutting Electrical Discharge Machining:

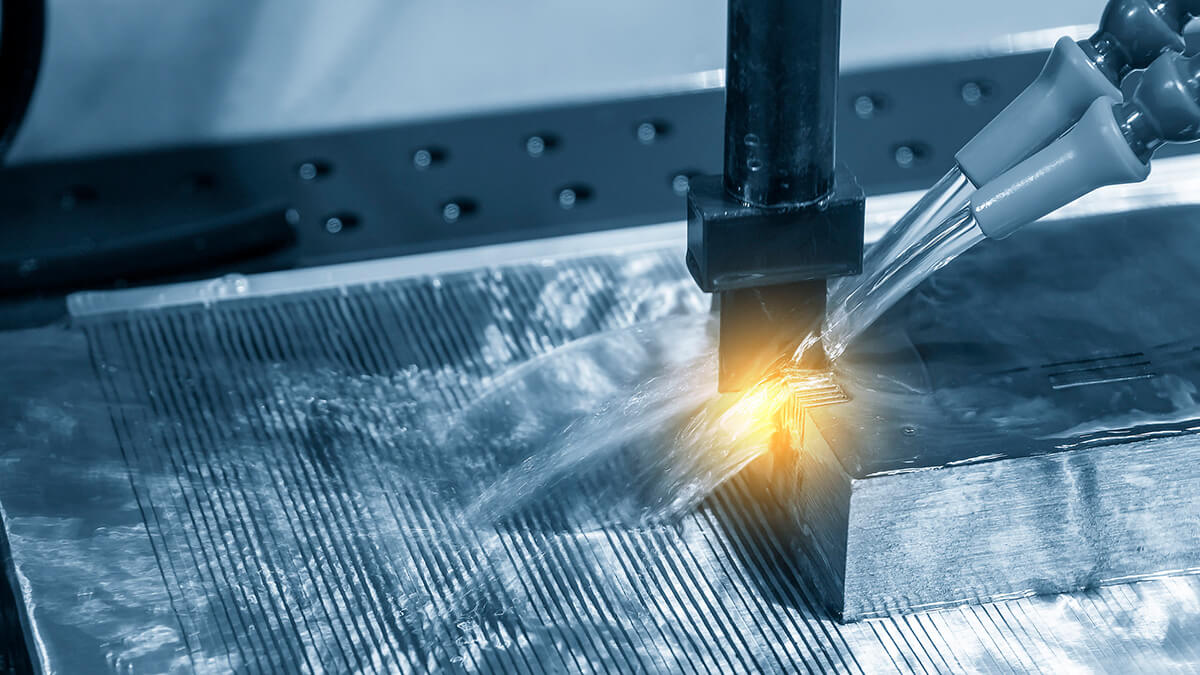

The use of thin wires to cut objects can also be referred to as wire erosion, wire burning EDM. In this type, the wire is used as an electrode, and the wire is continuously fed from the automatic feed with the spool during processing. If you need to carry out the cutting process in the middle of the object, you can use the small hole to drill the EDM to punch the object, then pass the wire through the hole, further electric discharge machining, the wire can be fixed by the diamond guide, the liquid is used Ionized water, while wires are usually made of brass or copper.

Sinker Discharge Machining:

The sinker EDM, also known as a die, traditional EDM or Ram EDM. The use of die EDM allows the user to produce complex shapes. This method requires the electrode (usually made of graphite or copper) to be pre-machined into the desired shape and then the electrode is sunk into the article to form a negative of its original shape.

Hole Drilling Electric Discharge Machining:

Drilling EDM, this process is used for drilling, and the EDM is capable of machining very small deep holes compared to conventional drilling methods. Besides, EDM drilling does not require any debarring. During this process, the electrodes are tubular and the dielectric fluid is fed through the electrodes themselves.

Usually, each conductive material can be processed by electrical discharge machining. Common materials include metals or metal alloys such as hardened steel, titanium, and composites. Typically, the electrodes for the electrospray EDM are made of copper or graphite. The main factors affecting the determination of the electrode material are the conductivity of the electrode and its corrosion resistance. The advantage of graphite is that it is easier to process than copper. However, copper has high electrical conductivity and strength. Brass is a copper and zinc alloy commonly used for wire EDM or small tubular electrodes. In contrast to the electrodes used for sinking, the wires used for EDM do not have to have good electrical resistance properties because new wires are continuously fed during the cutting process.

.jpg)

.png)