Permanent Magnetic Chuck: The Core Component and Precision Control in High-Speed Machining

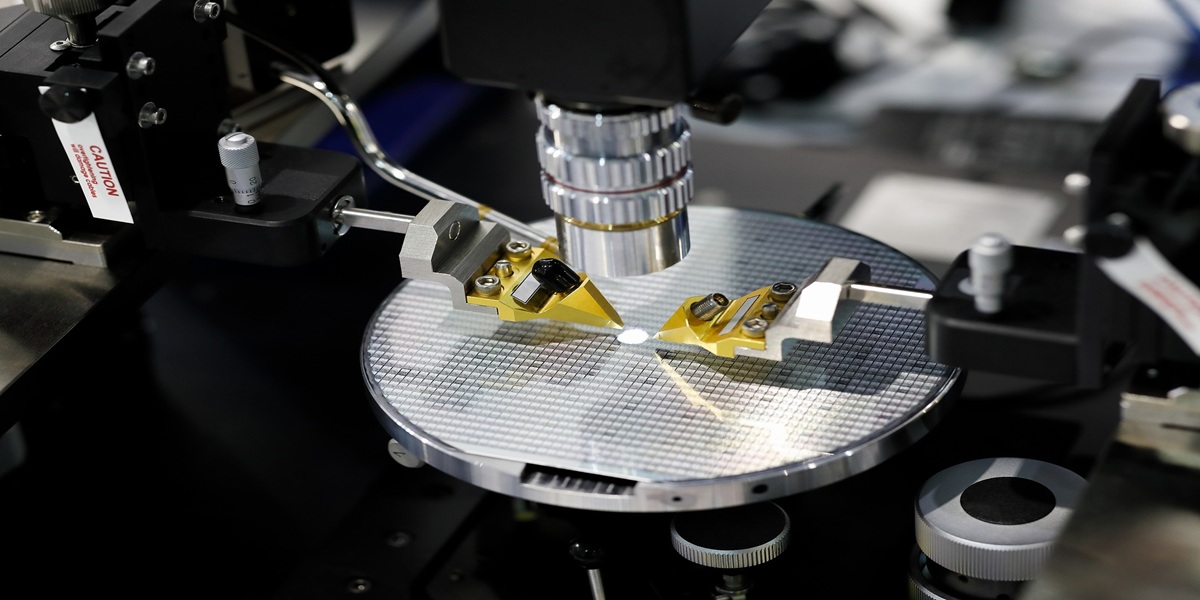

The Role of Permanent Magnetic Chuck in High-Speed Machining

Permanent Magnetic Chucks play a pivotal role as core components in these systems. They provide stable magnetic support in drive systems, effectively reducing the impact of vibrations and thermal expansion on precision during high-speed operations.

Challenges and Demands in High-Speed Machining

With the increasing demand for high-speed machining, CNC systems must operate under higher speeds and load conditions, putting stress on both machine components and overall system stability. The quality of Permanent Magnetic Chucks directly impacts machining precision, especially in high-precision industries like aerospace and automotive manufacturing.

Advantages of Permanent Magnetic Chucks

- High Stability and Precision:

- No External Power Supply:

- Reduced Thermal Displacement and Enhanced Durability:

- Improved Machining Efficiency:

- Fault Tolerance and Adaptability: These chucks maintain their function even under extreme conditions, ensuring reliability in critical industries.

- Eco-Friendly and Energy-Efficient: They are more environmentally friendly compared to electromagnetic devices, reducing both energy consumption and environmental impact.

Permanent Magnetic Chucks maintain constant magnetic force even under high loads, reducing vibrations and ensuring precision in every operation.

Unlike electromagnetic systems, Permanent Magnetic Chucks rely on built-in magnets, eliminating the need for external power supply and reducing energy consumption.

Their design and materials ensure stable magnetic force in high-temperature environments, increasing durability and reducing maintenance costs.

Stable performance enables higher speeds and reduces processing time, which is crucial for high-volume or precision manufacturing.

Earth-Chain’s Permanent Magnetic Chuck Solutions

Earth-Chain specializes in providing high-precision, high-performance Permanent Magnetic Chucks for industries like aerospace, automotive manufacturing, and precision machining. Their solutions help businesses improve machining precision, reduce errors, and extend equipment lifespan.

Technological Innovation and Quality Assurance

Earth-Chain’s Permanent Magnetic Chucks adhere to strict quality control standards and continuous innovation to ensure superior durability and precision. These chucks are engineered to meet the rigorous demands of high-speed machining environments.

Enhancing High Precision and Accuracy

As machining technology evolves, the importance of Permanent Magnetic Chucks becomes ever more critical. Earth-Chain's high-performance chucks are designed to help companies improve machining precision and tackle the challenges of modern manufacturing.