In recent years, due to the high demand for customized orders and small and diverse production, the production line must frequently replace molds and adjust lines. Mold replacements often take 2 to 3 hours, and production line adjustments may even stop production for a few days, resulting in production delays and making production capacity impossible. How can we effectively replace molds, adjust production lines, reduce downtime, and quickly respond to customer needs?

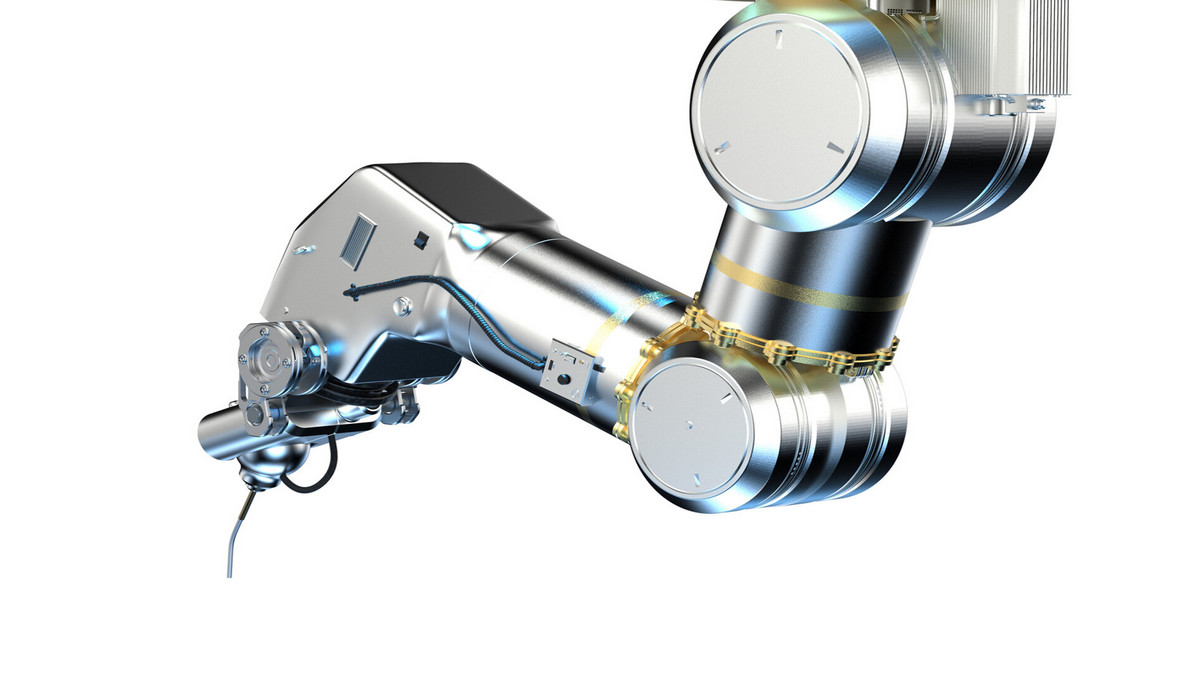

The robot arm is an automatic control device that imitates the function of the human arm and can complete various tasks. This robot system is multi-jointed and joints allow movement in a plane or three-dimensional space or use linear displacement. Structurally, it is composed of a mechanical body, a controller, a servo mechanism and a sensor, and a certain specified action is set by a program according to the operation requirements.

Using the robot arm for quick mold change to shorten the downtime of mold replacement, the production line can increase the flexibility of production. Faced with a small number of diverse customer needs, it can easily respond to urgent orders and insertion orders, complete orders on time, and receive payment on time, increasing corporate competition.

Several seniors for improvements with robot arm for quick mold change:

Improvement 1: The mold is replaced by the experienced master

In the manufacturing industry, whether it is an injection molding production line, or a metal stamping and cutting industry, usually changing molds/lines is the most time-consuming and laborious work. A lot of valuable production time was wasted during downtime and waiting.

In the past, when changing molds, it was necessary to rely on the experience of master craftsmen to set up molds and adjust molds, but now it is becoming more and more difficult to hire master craftsmen, and the cost is getting higher and higher. Many young people are unwilling to engage in related work, which stems from the fact that they are not familiar with factory operations. My impression is still of a man in dirty, oil-soaked overalls standing knee-deep in metal shavings.

In order to solve the problem of difficulty in hiring master craftsmen and high cost, it is the best way to introduce a "robot arm quick mold change system". The rapid mold change work is listed as a standard operating process management, which allows ordinary workers to go through simple training. Get started with the mold replacement operation. Due to the high precision of the mold change, there is no need to calibrate after the replacement, which greatly reduces the technical threshold for mold replacement.

Improvement 2: It takes 2 hours to half a day to replace the mold, which is time-consuming and labor-intensive!

In recent years, the production demand for small quantity and variety and customized orders has increased, which has led to the frequent replacement of molds and line adjustments on the production line. The replacement of molds takes two hours to half a day, and the adjustment of production lines may even stop production for a few days, resulting in production delays and making production capacity impossible.

For a quick mold change, it can automatically correct the loss of mold fixtures due to frequent use, and the repeat positioning is accurate. Achieve fast clamping and precise positioning, no need to correct after replacement, can quickly exchange processing molds and workpieces, while maintaining machining accuracy, can shorten the mold replacement time from two hours to half a day in the past to just a few minutes, and improve the production line efficacy.

Improvement 3: With the production of robotic arms, automatic loading and unloading can achieve twice the result with half the effort!

With the robot arm, it can realize automatic loading and unloading of multiple CNC machines by one robot arm on workpieces with a production cycle of more than one minute. Maximize benefits! This can greatly reduce the labor cost and manpower shortage pressure of the enterprise, and the original operators can also switch to other higher value-added jobs.

In Conclusion

Changes in the manufacturing environment, from changes in customer order patterns to increases in personnel supply and labor costs, all test the wisdom of operators. Quick mold change can help manufacturers reduce labor costs, reduce downtime and waiting time, and improve production Flexibility, thereby increasing the competitiveness of enterprises!

The introduction of quick mold change and automation can be tried on a small scale. For example, you can first select products and production lines that frequently change molds, or the scope of a single factory area, and start importing. After the successful model is determined, it will be slowly copied to a larger field. The era of robots is coming and maximize the benefits it might bring to the industrial world.

.jpg)

.jpg)