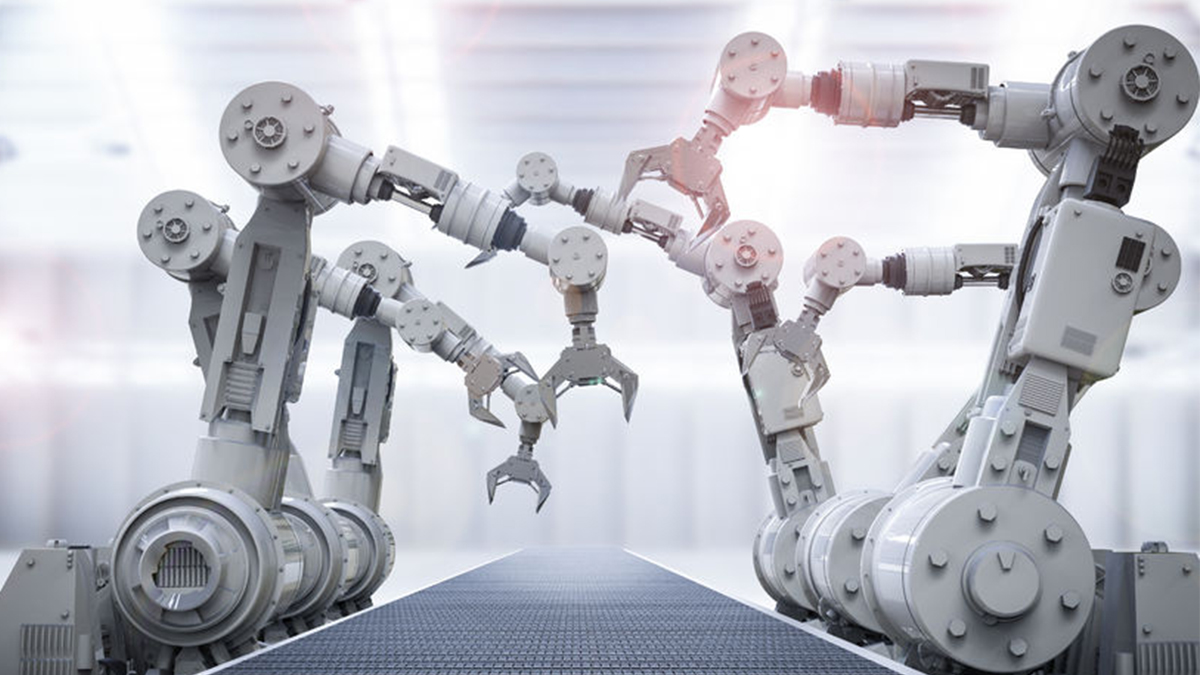

The world has entered the era of Industry 4.0. robots assist human manufacturing, emphasizing the use of "human-machine collaboration" to move toward smart production. In recent years, the population aging problem faced by developed countries has caused the production costs of industry and manufacturing to increase year by year. Enterprises have deployed automation equipment to improve production efficiency. Various industries have also undergone tremendous changes in this intelligent wave.

The Market Moves Towards Smart Manufacturing

Robotics and Machine Vision are different in professional research fields. Robotics usually belong to the fields of mechanical engineering and automatic control engineering; while machine vision belongs to information engineering and electrical engineering. Through the cooperation of experts in these two major fields, the robot can be given the ability of visual perception. It can be seen that robot vision is a highly integrated engineering technology that detects people and objects in the environment through machine vision, calculates their position on the camera coordinate system, converts to the robotic arm coordinate system, and then drives the motor Driving the shaft joint to operate the target is a seemingly simple process, but in fact, it implies complex computer operations.

The hand-eye relationship has its own advantages and disadvantages. The relative position determines the arm-camera cooperation mode. Traditional robotic arm programming uses the teaching of multiple arm movement points, allowing the arm to repeat the same action at the same point. Because the points are fixed, a large number of jigs are needed to fix the workpiece or the peripheral processing machinery, and the application flexibility is poor. And once an earthquake or external force changes the relative relationship between the arm and the objects in the working area, all points must be taught again. If the arm is combined with machine vision, the position of the arm can be flexibly corrected through the ability of visual recognition and compensation, and the use of jigs can be effectively reduced, and the flexibility to handle diverse and multi-posture workpieces can be increased.

How the robot arm and the camera (vision) cooperate depends on the spatial relationship between the arm and the camera, also known as the hand-eye relationship, which can be divided into "Eye-in-Hand", "Eye-to-Hand" and "Upward-looking".

Eye-to-hand means to hang the camera on the end shaft of the arm. After the camera is taken and visual recognition is completed, the arm is driven to clamp the workpiece; the eye-to-hand means that the camera and the arm are fixed in two positions separately, and the camera is capturing images The arm can move at the same time during identification, so there is better cycle time, but it must be used to ensure that the arm holder and the camera maintain a fixed relative relationship, if the relationship between the two changes, you need to re-calibrate; As for the eye view hand structure, also known as secondary positioning, when the arm grips the workpiece, it moves into the camera field of view, compares the difference between the current posture and the standard posture, and then performs further posture compensation. This mode can have better positioning accuracy.

Mechanical Arm Integrated Vision

Needs to rely on professional system integration, import automation first, precision and production cycle

The integration of robotic arms and machine vision is not an easy task with the current industrial development. If the end customer does not have a certain degree of engineering capability, he still needs the assistance of a system integrator with professional knowledge. For the arm, the system integrator must first consider the arm length and load when selecting a suitable arm. The arm length can ensure an effective working range. Regarding the load, it is necessary to calculate the end effector and the workpiece such as the gripper. Whether it can meet the rated load range of the arm work.

On the other hand, there are various options for the integration of visual solutions. For situations with multiple camera requirements and high computing burden, a vision controller is often used. The hardware is essentially an industrial computer, which usually supports two to four industrial cameras and has built-in image recognition software, allowing users to program the visual recognition problem they want to solve. Another type of product is the smart camera, which itself is an embedded computing platform with CCD/CMOS sensors. Users can choose a suitable lens for their working field of view. The platform also contains visual processing software, but the computing performance Inferior to the visual controller, it is usually used in code reading and positioning. In addition, some system integrators, in order to save costs or increase flexibility, will integrate commercial or free visual libraries and develop dedicated software.

In addition to considering the appropriate arm model and vision solution, the most important indicators when evaluating the feasibility of an automated case are precision and cycle time. Sufficient accuracy can ensure the correctness of each process, and the expected production cycle can be used to evaluate whether the production capacity is increased with the introduction of automation and calculate the return on investment (ROI). For the aforementioned accuracy part, if the object is positioned through vision, the factors that affect the overall accuracy include camera resolution, positioning algorithm, hand-eye relationship correction error, camera lens correction error, arm repeatability, and absolute accuracy, etc., which need to have relied on only experienced machine vision technicians can effectively evaluate.

Built-in vision in the arm greatly reduces integration costs

In recent years, collaborative robots have more advantages over traditional robots due to their high safety, ability to work in the same environment with workers, easy programming, and low learning thresholds for users. Brought a new wave. In addition, some robotic arm manufacturers, even integrate the vision module directly into the arm and become a standard product for sale. Users only need to use a single built-in software to complete the arm movement process teaching and visual process editing, which greatly reduces the user's original cost of integrating the arm and vision, and effectively reduces the time for system adjustment.

Looking to the future, with the improvement of visual sensing technology and the rapid development of artificial intelligence, the image information obtained by the camera can be upgraded from 2D to 3D, and even RGB-D, which contains richer color and geometric information, and artificial intelligence is used to identify the improvement of the robot will be able to more effectively solve the variation of the posture, object distance, and shape of the object. The robots of the future are bound to have more ability to sense the environment and understand the user. They can pay attention to the technological improvement added by the robot arm in the future. The coming process innovation.

Smart tools to build a smart manufacturing ecosystem

Companies need to build automation solutions that meet their own needs, but it is impossible to redesign production equipment for different manufacturing processes and applications. Therefore, companies must choose the best robot parts to maximize the benefits of automatic production for the company. When using robots, the use of appropriate accessories allows the company to smoother the processes from procurement, installation, an operation to redevelopment, and ultimately successfully shorten the manufacturing life cycle.

End-of-arm tooling (EOAT) is usually installed at the end of the robotic arm to perform various tasks. For example, robot grippers can handle various materials flexibly; or robust sensors that will issue alarms and correct the position of the robot in time; and the robot tool quick-change device can speed up the change of tools used. When the robot is equipped with these advanced tools, it can be transformed into a smart device with sensing, action, and behavior capabilities, which can be easily used in smart manufacturing.

The accessories of the new generation of smart robots can meet the requirements of smart manufacturing for innovation, professionalism, and accuracy. These accessories have also changed the economic patterns of industry, manufacturing, e-commerce, and agriculture. These industries have gradually introduced robotic arm terminals Tools, built-in technology, and intelligent functions, thus greatly reducing manufacturing costs and time.

If Taiwanese companies can promote smart manufacturing at a lower cost, they will be able to lead the manufacturing industry to a new course and accelerate the pace of Taiwan’s Industry 4.0. The application of smart robot terminal tools is to promote enterprise automation that is both affordable and highly feasible.

As the application of automated robots is becoming more and more popular around the world, the prospects of robotic arm terminal tools are also very promising; the global robotic arm terminal tools market will reach 9.2 billion US dollars in 2020, with a compound annual growth rate (CAGR) of nearly 9%. The International Federation of Robotics said that by 2021, the number of robots supplied to factories worldwide will reach 630,000 units each year, and the annual compound growth rate will be as high as 14%.

Accelerate the Popularization of Smart Automation

When implementing customized solutions, using robots equipped with robotic arm terminal tools can improve work efficiency and allow companies to create new applications, because robotic arm terminal tools can effectively improve the efficiency and flexibility of robots. In fact, the efficiency of the automated process and the grippers mounted on the robot are closely related to other smart tools.

Modern grippers and power sensors show the infinite potential of smart robot accessories. In collaborative applications, companies not only hope that machines can perform highly efficient automated tasks-they also hope that they can operate robots remotely and diagnose problems online. Smart robotic arm terminal tools equipped with smart hardware and software can help collect and analyze data and provide timely feedback to enhance the function of the robot.

Through the robotic arm terminal tool, the machine can be lighter, smarter, and more autonomous, and can efficiently execute various human-machine collaboration applications, making automated operations easier and more economical for enterprises.

Choosing the right robot accessories is a necessary-the benefit of using the robot depends on the tools and accessories installed on the robot. The robotic arm terminal tool allows two-way communication between the tool and the robot to improve operating efficiency and productivity. For example, high-precision grippers can use built-in technology to imitate the actions of human fingertips, such as picking and placing fragile items, so that they will not cause damage to the picked items.

Robotic arm terminal tools push the possibility of human-machine interaction to a higher level-because modern gripper is so precise that they can even grip wafers used to manufacture computer processors, and torque sensors can be more precise in positioning and detect where the object is. These grippers with built-in sensors can be used in a precise manufacturing process and effectively complete the work.

Modern industrial environments require application-oriented solutions

For special production operations, some companies adopt traditional methods and create customized tools based on different business models. However, this method not only increases the company's cost but also the process is inflexible. On the other hand, grippers, sensors, or other applications are more applicable. Oriented solutions can be customized for different shapes, sizes, and materials. In contrast, companies that use traditional manufacturing methods are quite disadvantaged in terms of business opportunities.

These terminal tools are not only flexible but also versatile, suitable for various manufacturing environments. Their adaptability, built-in advanced technology, and smooth information assimilation capabilities can help shorten the manufacturing cycle and reduce downtime. The advantages of the terminal device provide more options for other hardware solutions, reduce the cost of introducing robotic solutions, and at the same time lower the barriers to adoption of automation. All in all, the use of robotic arm terminal tools can save enterprises money.

Fully automated solution

The rapid development of technology drives the transformation of all walks of life. In order to reduce costs and increase operational flexibility, companies must take automated manufacturing into consideration. In order to achieve the above goals, robot accessories that play an important role in collaborative applications need to become smarter. By introducing smart technologies and tools, companies can meet the increasing demand for industrial mechanization.

.jpg)