The manufacturing of construction screws involves multiple carefully controlled steps to ensure high quality and durability. It begins with selecting suitable raw materials, usually low-carbon steel wire, followed by cold heading to form the screw head. Threads are then created through thread rolling, which preserves the metal’s strength better than cutting. Heat treatment enhances hardness and toughness, while surface coatings protect against corrosion. Rigorous quality control is maintained throughout the process, and finally, the screws are packaged for safe transportation. Each stage is crucial to producing reliable screws capable of withstanding tough conditions in construction and industrial use.

The manufacturing of construction screws is a complex and detailed process, consisting of several essential stages that ensure the final product’s quality and durability. Construction screws play a vital role in construction projects, woodworking, and industrial applications by securely fastening materials and enduring significant stress, environmental factors, and long-term use (Fong Prean Industrial Co., Ltd., 2025). This article explores the step-by-step process involved in producing construction screws, emphasizing the significance of each phase and the technologies applied.

Referral Link

Selection and Preparation of Raw Materials

The initial phase in producing construction screws is the careful selection of raw materials. Generally, low-carbon steel wire is preferred due to its ideal combination of strength and flexibility. However, other metals such as stainless steel, brass, nickel, or aluminum may be chosen depending on the application requirements. The wire must be prepared thoroughly, ensuring it is free from contamination and meets strength standards before proceeding.

Heading Process

Heading involves shaping the screw head through a technique known as cold heading. During this cold working process, the wire is drawn from a coil and straightened, then automatically cut to the correct length. The head is formed by pressing the wire into a die shaped to produce the desired head style - such as flat, pan, bugle, or hex. The die’s design determines the screw head’s final shape and features.

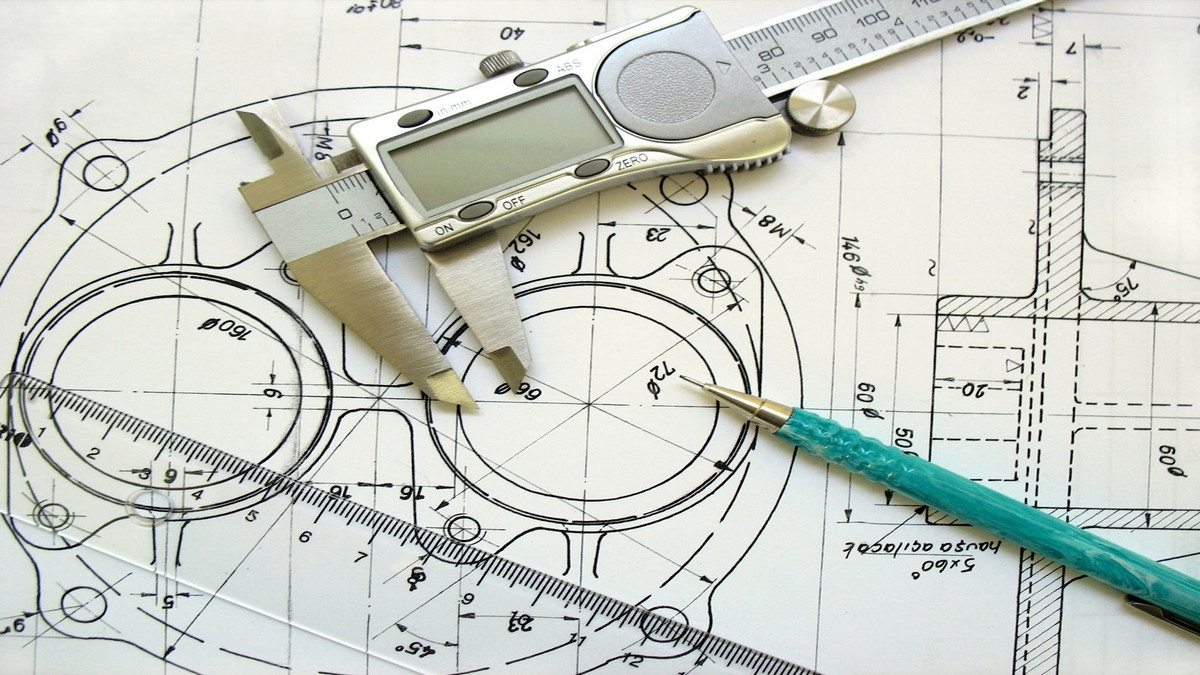

Thread Rolling

Thread rolling is a crucial step where the screw’s threads are formed by pressing the blank between specially shaped dies. The primary thread rolling methods include flat dies, two-die cylindrical, three-die cylindrical, and planetary dies. This process shapes the threads by rolling rather than cutting, which preserves the metal’s integrity and enhances thread strength and durability.

Heat Treatment

To improve hardness and toughness, screws undergo heat treatment involving controlled heating and cooling cycles. This process strengthens the screws and increases their resistance to wear and fatigue. Carbon steel screws, in particular, benefit from hardening and tempering to achieve the required mechanical properties.

Surface Coating

Surface finishing protects screws from corrosion and enhances their visual appeal. Common coatings include zinc electroplating, phosphate, and other finishes that prevent rust and extend the screws’ lifespan. Applying these coatings is essential to ensure screws can withstand challenging environmental conditions without compromising their strength.

Quality Control

Quality control is a critical component throughout the manufacturing process. Rigorous inspections and tests are conducted at various stages - from raw material selection to final packaging - to ensure the screws meet industry standards and performance criteria.

Packaging and Shipping

After passing all quality checks, the screws are carefully packaged to protect them during transportation and storage, ensuring they arrive in excellent condition for end-users.

Conclusion

The manufacturing of construction screws is a meticulous, multi-stage process designed to produce reliable, high-performance fasteners essential for many industries. Each step - from choosing the right materials to thorough quality assurance - plays a pivotal role in delivering screws capable of withstanding demanding conditions. As manufacturing technologies continue to advance, the production process will evolve further, improving screw performance and broadening their applications.

.png)