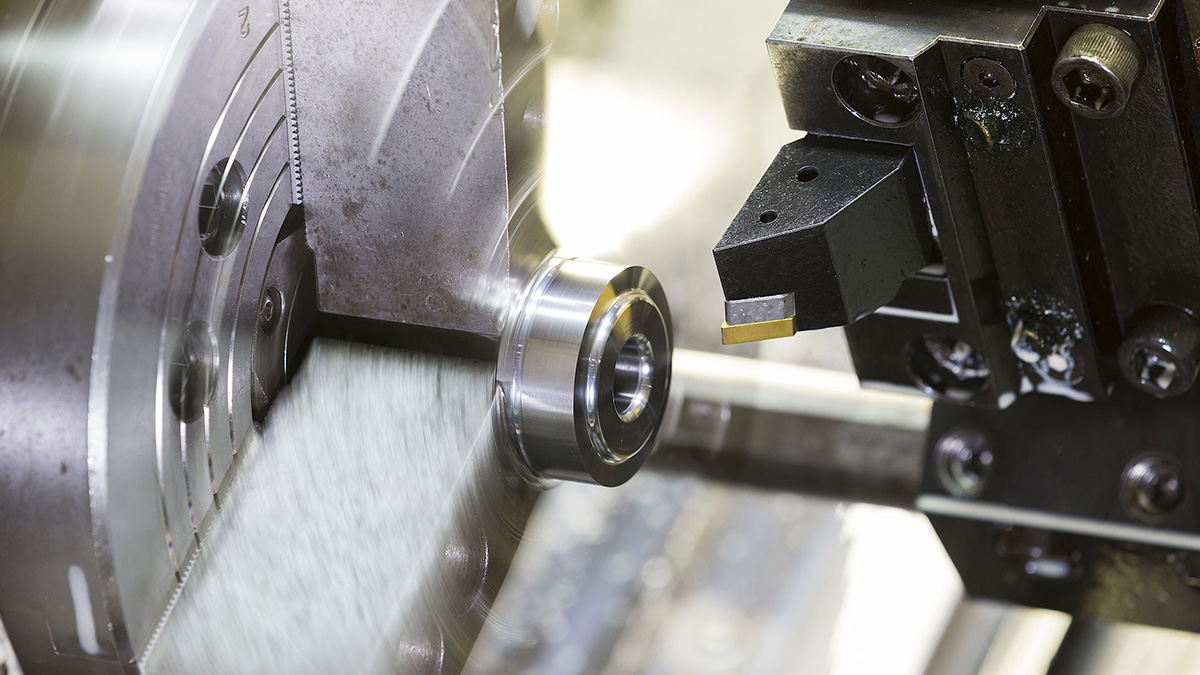

The principle of grinding precision machining: Grinding is an abrasive precision machining method that uses a lapping tool and abrasive to grind off a thin layer of metal from the surface of the workpiece based on fine machining.

What Is Grinding Process?

Define grinding:

Grinding is a unit operation that reduces solid matter into smaller particles.

Define grinding process:

Grinding is a processing method that uses abrasives to remove material. The process of removing material with abrasives is one of the earliest production techniques used by humans.

Grinding process is a micro-processing method. Grinding uses a grinding tools and abrasive (a free abrasive) to generate relative movement between the processed surface of the workpiece and the grinding tool, and apply pressure to remove it from the workpiece. Tiny surface raised layer to reduce surface roughness and improve dimensional accuracy, geometric accuracy, etc. Grinding process can be used in various metal and non-metal materials. The processed surface shapes include flat surfaces, inner and outer cylindrical and conical surfaces, convex and concave spherical surfaces, threads, tooth surfaces, and other profiles. In-mold manufacturing, especially precision die-casting molds, plastic molds, and automobile panel molds that require high product appearance quality are widely used.

What Is the Working Principle of Grinding Machines?

During the grinding process, the grinding surface of the grinder tool is evenly coated with abrasive. If the material hardness of the grinding tool is lower than that of the workpiece, when the grinding tool and the workpiece move relative to each other under pressure, the abrasive has sharp edges and corners. Some of the particles with high hardness will be pressed into the surface of the lap to produce cutting action (plastic deformation), and some will roll or slide between the grinding tool and the surface of the workpiece to produce slippage (elastic deformation). These particles, like countless cutting blades, produce a small amount of cutting action on the surface of the workpiece, and evenly cut a thin layer of metal from the surface of the workpiece. At the same time, under the action of the grinding pressure, the passivated abrasive particles squeeze the peak points of the processed surface to produce micro-extrusion plastic deformation on the processed surface, so that the workpiece gradually obtains high dimensional accuracy and low surface roughness.

When using abrasives such as chromium oxide and stearic acid, the abrasive and the processed surface of the workpiece have a chemical effect during the grinding process, resulting in a very thin oxide film, which is easily worn off. The grinding process is the process of continuous generation and erasing of oxide film, so many cycles of repetition reduce the roughness of the processed surface.

What Are the Types of Grinding Processes?

- Manual grinding:

The relative movement of the grinder machine and the workpiece is operated manually. The processing quality depends on the skill level of the operator, the labor intensity is high, and the work efficiency is low. Suitable for various surfaces of various metal and non-metal workpieces. The local narrow slits, slots, deep holes, blind holes, and dead corners on the mold forming parts are still mainly hand-grinded.

- Semi-mechanical grinding:

One of the grinder machine and workpiece adopts simple mechanical movement, and the other adopts manual operation. The processing quality is still related to the operator's skills, and the labor intensity is reduced. Mainly used for grinding the inner and outer cylindrical, flat, and conical surfaces of the workpiece. Commonly used when grinding mold parts.

- Mechanical grinding:

The movement of the grinder machine and the workpiece adopts mechanical movement. The processing quality is guaranteed by mechanical equipment, and the work efficiency is relatively high. But it can only be applied to the grinding of parts such as the surface shape is not too complicated.

Conditions of Use of Abrasive

- Wet grinding:

During the grinding process, the abrasive is applied to the surface of the grinding tool, and the grinding material rolls or slides between the grinding tool and the workpiece, forming a cutting effect on the surface of the workpiece. The processing efficiency is high, but the geometric shape and dimensional accuracy, and gloss of the processed surface are not as good as dry grinding. It is mostly used for rough grinding and semi-finishing of flat surfaces and inner and outer cylindrical surfaces.

- Dry grinding:

Before grinding, the abrasive particles are evenly pressed into the working surface of the grind to a certain depth, which is called sand embedding. During the grinding process, the grinding tool and the workpiece maintain a certain pressure and move relative to a certain trajectory to achieve micro-cutting, thereby obtaining high dimensional accuracy and low surface roughness. During dry grinding, generally no or only a small amount of lubricating abrasive is applied. It is generally used for the fine grinding of planes, and the production efficiency is not high.

- Semi-dry grinding:

Using paste grinding paste, like wet grinding. When grinding, according to the requirements of workpiece processing accuracy and surface roughness, apply the grinding paste promptly. It is suitable for rough and fine grinding of all kinds of workpieces.

Applications of Grinding Technology

- Low surface roughness:

Grinding with surface grinder belongs to micro-feed grinding, and the cutting depth is small, which is beneficial to reduce the surface roughness value of the workpiece. The surface grinding machine processed surface roughness can reach Ra0.01μm.

- High dimensional accuracy:

Grinding uses extremely fine micronized abrasives, and the machine tool, grinding tool, and workpiece are in an elastic floating working state. Under the action of low speed and low pressure, the convex points of the processed surface are successively ground, and the processing accuracy can reach 0. 1μm~0.01μm.

- High shape accuracy:

When grinding, the workpiece is basically in a free state, the force is uniform, the movement is stable, and the movement accuracy does not affect the shape and position accuracy. The cylindricity of the processed cylinder can reach 0.1μm.

To improve the mechanical properties of the surface of the workpiece:

The grinding heat is small with surface grinding machine, the deformation of the workpiece is small, the metamorphic layer is thin, and there will be no micro-cracks on the surface. At the same time, it can reduce the surface friction coefficient and improve wear resistance and corrosion resistance. There is residual compressive stress on the surface of the ground part, which is conducive to improving the fatigue strength of the surface of the workpiece.

.png)