Milling is a machining method in which a milling cutter is used as a tool to process the surface of an object. Milling is a highly efficient machining method in which a rotating multi-blade tool is used to cut a workpiece.

What is the Milling Process?

Milling refers to a technique of moving the relative position of a workpiece such as metal to a tool while cutting or drilling a hole in the material to give the material the desired shape. When working, the tool rotates as the main movement, the workpiece moves as the feed movement, and the workpiece can also be fixed, but the rotating tool must complete the main movement and the feed movement at the same time. Machine tools for milling include horizontal milling machines, vertical milling machines, or gantry milling machines. These machine tools can be ordinary machine tools or CNC machine tools. Cutting with a rotating milling cutter as a tool. Milling is generally carried out on a milling machine or a boring machine and is suitable for processing planes, grooves, various forming surfaces, and special shapes of molds.

Milling can be roughly divided into two types: Milling in which the workpiece to be machined is fixed and rotating the tool, and turning in which the workpiece is rotated.

What is Milling Machine Processing?

Milling machining is a method of machining with a cutting tool called a milling machine mounted on a rotating shaft. Because it allows the tool to intermittently contact and cut the fixed workpiece, it can not only machine the surface of the workpiece into a flat or curved surface but also perform various operations such as drilling and grooving.

Milling machines can be divided into horizontal and vertical types according to the spindle direction of the installation tool, and there are also gantry-type milling machines, which can use tools such as face mills, end mills, and slot mills to machine workpieces into target shapes.

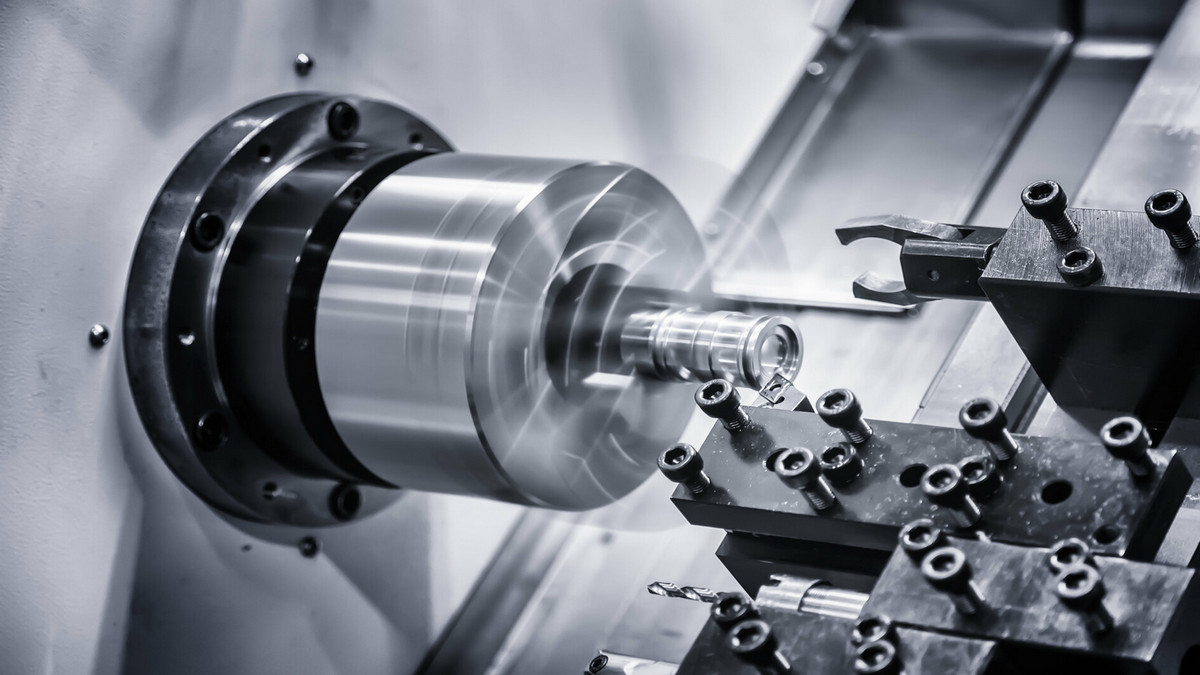

What is Lathe Machining?

Lathe processing is generally divided into two categories: material moving, tool moving, and tool moving and material moving. Lathe machining technology can be used to process the workpiece with a lathe to make the outer periphery of the workpiece into a round shape or a shape with a thin end, or perform drilling, boring to enlarge the hole diameter, thread cutting, and grooving. The workpiece can be completely cut off.

Precision Correction for Milling:

- X-axis calibration of milling machine:

Slightly loosen the 4 bolts, but make sure that the 4 bolts still have some frictional resistance. Currently, use the head to rotate the bolts to adjust the left and right angles. During the process, a dial indicator must be placed on the end face of the main shaft to measure the correct position of the worktable.

- Y-axis calibration of milling machine:

Slightly loosen the three bolts, but make sure that the three bolts are not too loose to facilitate fine-tuning work. Use the arm rotating bolt to place a dial indicator on the end face of the shaft to measure the correct position of the worktable.

- Leveling of milling machine:

Place the spirit level on the work surface.

What are the Processing Objects?

- Plane parts:

The characteristics of plane parts are that the machined surface can be parallel to the horizontal plane, perpendicular to the horizontal plane, and can also form a fixed angle with the horizontal plane. The simplest type of parts in CNC milling, generally only need to use the two-axis linkage or three-axis linkage of the three-coordinate CNC milling machine to process. During the machining process, the machined surface is in surface contact with the tool, and end mills can be used for both rough and finish machining.

- Surface parts

The characteristics of surface parts are that the machining surface is a space surface, and during the machining process, the machining surface and the milling cutter are always in point contact. Surface finishing is mostly carried out with ball-end milling cutters.

What are the Factors that Affect Machining Accuracy?

- Rigidity:

Once a force is applied to an object, the object deforms, but on the other hand, it produces a force that resists the deformation, such a property is called rigidity. When using a machine tool, the rigidity of the machine tool needs to be overcome if machining is to be performed with target accuracy. Although the ability of current machine tools to cope with rigidity is quite high, to perform machining with micron-level accuracy, it is necessary to understand the rigidity characteristics. Rigidity is divided into static force (static rigidity) and dynamic force (dynamic rigidity). When performing machining such as cutting on the workpiece, both static and dynamic rigidity must be considered at the same time.

- Static rigidity: Refers to the state in which the direction and magnitude of the acting force remain fixed at any time. In the machine tool, it can be said that the operation part is in a state of being stationary on the work plate. At this time, from a rigorous point of view, it can be considered that the work place has been deformed by the influence of the gravity of the operation part. Although the actual effect is small, it may still reduce the machining accuracy in some cases.

- Dynamic stiffness: Refers to the state in which the direction or magnitude of the applied force is changing. In the case of a machine tool, vibration is generated when the switch is turned on to make the machine run. This may cause symptoms such as chattering of the machine tool, affecting machining accuracy.

- Thermal deformation:

Objects expand as their temperature rises. Therefore, to accurately measure the length, it is necessary to perform work in a measurement room that thoroughly implements temperature management. During processing, special attention should be paid to the deformation of objects caused by heat. This is because each part will heat up after the machine tool is running. In addition, when performing operations such as cutting, the temperature of the target object also rises. And the longer the machine tool runs, the less the influence of thermal deformation can be ignored. Therefore, knowing how long the operating time will bring the machine to a high temperature can be said to be important in precision machining.

Basic Knowledge of Cutting:

- Cutting action:

Cutting refers to the action of using a tool to shave off a part of the target, and it needs to be followed by two actions. Cutting is the action of shaving off a part of the target and is performed by moving a tool such as a turning tool in a straight line. Feed refers to the action of moving the tool so that the machine can cut other parts. For example, after putting on a straight line, a new face can be cut by feeding the tool in a direction perpendicular to the cutting direction. Just repeat this action to create a plane.

- Processing and resistance:

Since the tool and the target are in contact with each other during processing, and the forces interfere with each other, resistance occurs. When working, it must be considered that the resistance produced by different tools is different. When cutting with a turning tool, the resistance will vary depending on factors such as the material of the target, the cutting area, or the type of turning tool. Among them, the cutting area has a great relationship with the resistance, and special attention must be paid during processing. In addition, when drilling with a drill, it is also necessary to consider resistance for torque and feed. Moment refers to the strength of the twist, also known as torque. Feed refers to the action of advancing the direction of the drill. When drilling, in addition to the material of the target, the resistance value varies depending on the type of drill (tip shape), drill rotation speed, and feed rate. At the machining site, it is possible to pursue quality, efficiency, and tool durability if the machining method is considered while considering the influence of resistance.

- Processing and speed:

At the processing site, work efficiency is an important issue as well as quality control. The use of machining is to increase efficiency by increasing the processing speed.

However, special attention should also be paid to increasing the speed of machinery and processing, which may cause negative effects such as increased resistance and thermal deformation. In addition, increasing the machining speed may also shorten the life of the turning tool. This may increase the frequency of changing turning tools, making the cost per machining unit higher. Therefore, it is important to consider speed and accuracy before machining, as well as tool life.

- Processing and temperature:

When performing machining such as cutting, heat is generated when the target and the tool encounter each other. This may increase the temperature inside the target, affecting machining accuracy or tool durability. The faster the processing speed, the more heat is generated. The larger the machining area, the greater the friction, which will increase the temperature. Therefore, when performing machining, please keep an eye on temperature changes while working. Cutting fluids play an important role in the temperature management of machining. It can reduce the wear difference between the target and the tool, so it can reduce the heat generated during the cooling process and reduce the waste generated by the process. In the past, most cutting oils were oil-based. But now, due to the increased awareness of environmental protection, most of them have changed to water-soluble cutting oils. In addition, because machining requires a large amount of cutting oil, most manufacturers now use a circulating type device to filter the used cutting oil and reuse it again.

Important Maintenance Tips for Milling Machines:

- Lubrication:

One way to keep your milling head tools in good condition is to make sure they are well lubricated. For milling heads to work properly, they must have proper lubrication so that all parts move smoothly.

- Cleaning:

Another important key to keeping your machine functioning is to ensure proper cleaning after use. Many machine parts are regularly exposed to dust and other contaminants, so keep the milling head clean to prevent any problems.

- Daily inspection:

Problems can be prevented by performing daily inspections.

.jpg)

.png)