- Showing results for

- Global

In the present day, conventional industries are blending Internet of Things technology to drive the evolution of Industry 4.0 and the advancement of smart manufacturing.

2023-10-27 10:30:52

Are you familiar with the latest terminology related to Tooling 4.0? In this article, we'll offer an overview and examples that can help manufacturers understand and align with this evolving concept. Tooling 4.0 revolves around leveraging technology to transform 'inefficient' products into 'intelligent' ones.

2023-10-27 10:42:06

Anodization is a surface treatment process, typically performed as the final step in metal manufacturing. It is a dependable and cost-effective method for enhancing wear resistance and adding color to precision machined metal parts, particularly aluminum and other non-ferrous metals.

2023-11-03 13:25:22

In most cases, blackening treatment on steel, also known as black oxidation, can enhance corrosion resistance to a certain extent. However, the protective effect remains somewhat limited. To significantly improve both corrosion resistance and lubrication of the blackened layer, additional measures like oil immersion or subsequent rust prevention treatment are still necessary.

2023-11-03 13:33:55

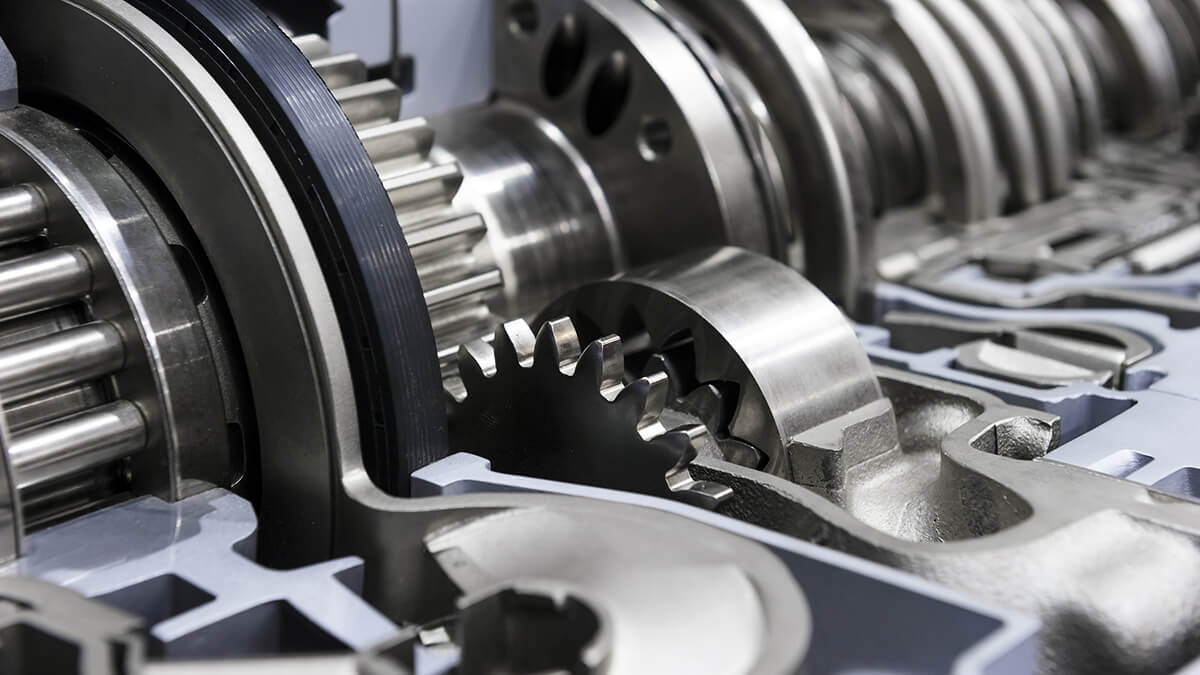

The worldwide manufacturing sector is shifting toward smart manufacturing, with Industry 4.0 leading the way by promoting greater efficiency, reduced costs, and intelligent, adaptable production processes. The nine key technologies of Industry 4.0 encompass Big Data, Layered Manufacturing, Cloud Technology, Automation, System Integration, Internet of Things, Cybersecurity, Augmented Reality, and Simulation.

2023-11-03 13:57:30

Defects are bound to occur during the reprocessing of mechanical equipment or metal parts. As a result, the final step of surface treatment holds significant importance. It serves the dual purpose of enhancing the aesthetics and protecting the surface, ultimately improving the performance of metal components and preventing rust.

2023-11-03 14:08:28

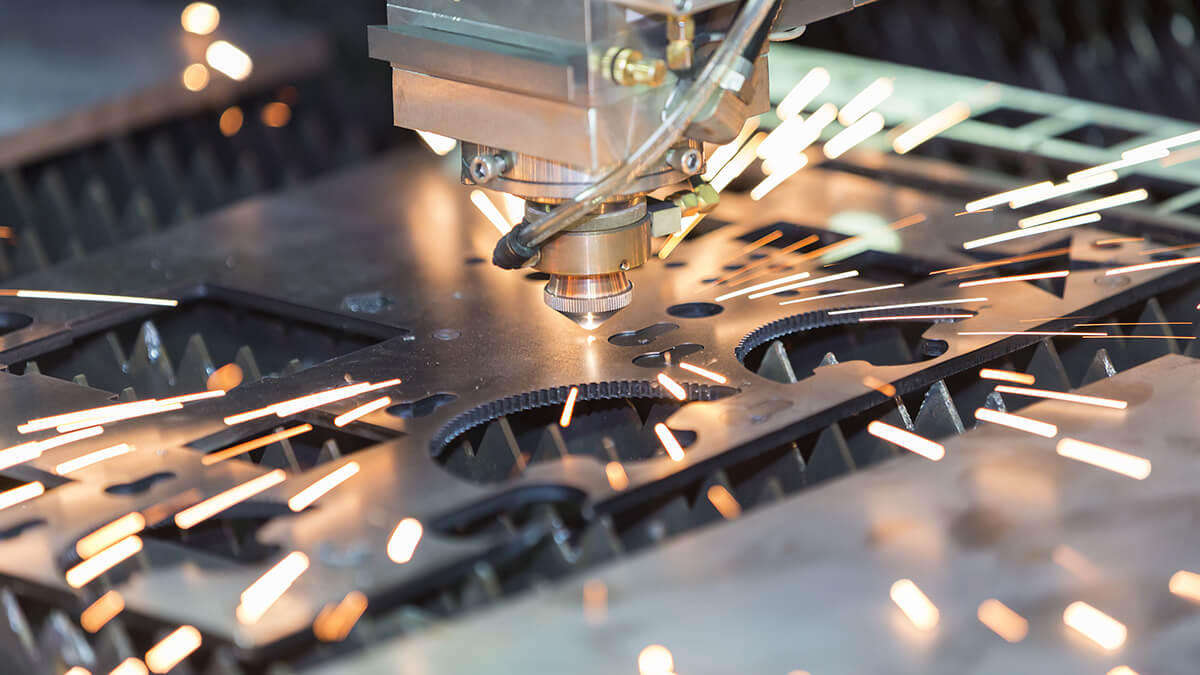

Cutting technology encompasses various processing methods, with laser cutting being capable of fulfilling intricate and highly precise cutting demands. It is a prevalent technique widely used in industrial manufacturing.

2023-11-07 13:34:10

When comparing laser cutting technology to traditional cutting methods, laser cutting offers superior precision, as it utilizes a high-intensity laser beam to cut through materials with exceptional accuracy, even for intricate details.

2023-11-07 13:59:00

Let's explore the definitions of planers and shapers. Planers and shapers are both machine tool applications frequently found in the machine tool industry.

2023-11-07 14:08:10

Shaper machines are intricate pieces of equipment designed for precision machining. They comprise several essential components, each contributing to the machine's overall functionality and effectiveness. To gain a comprehensive understanding of how a shaper machine operates, it's crucial to examine the role and interplay of these individual parts within the complete system.

2023-11-07 14:16:03

A shaper is a machine tool that employs the relative linear motion between a workpiece and a single-point cutting tool to shape a linear toolpath. Its cutting process is similar to that of a lathe, but it typically follows a linear, as opposed to a helical, trajectory.

2023-11-07 14:25:45

What is AOI? AOI stands for automatic optical inspection technology, known for its non-contact nature, rapid speed, high precision, and stability. This technology effectively addresses the limitations of manual visual inspection in quality management.

2023-11-17 13:27:02

The primary advantage provided by various types of CNC machine tools is enhanced automation, as it allows for the reduction or elimination of operator intervention in the production of workpieces.

2023-11-17 13:41:14

The term originates from English, known as plate metal. Typically, certain metal sheets undergo plastic deformation either manually or through die-stamping to attain the desired shape and size. These sheets can then undergo additional shaping through welding or a limited amount of mechanical processing to create more intricate components.

2023-11-17 13:49:43

In light of the evolving global industrial demands, the laser industry and technology are shifting towards meeting the requirements of 5G semiconductors and advanced processes for smart vehicles. While Taiwan's laser industry has made substantial progress over the years, maintaining alignment with international advancements necessitates a proactive push in independent laser technology.

2023-11-17 14:07:13

There are two types of RFID systems: passive and active. For those unfamiliar with RFID, you may be curious about the distinctions between these types and which one suits your application best. In the following, we offer a brief explanation.

2023-11-17 14:25:52

Hydraulic presses find applications in compaction, assembly, pressing, forming, embossing, and stretching. They play a crucial role in compaction within the cosmetics sector, assembly in the automotive industry, molding of electronic products, and stamping in the home appliance industry.

2023-11-24 14:39:03

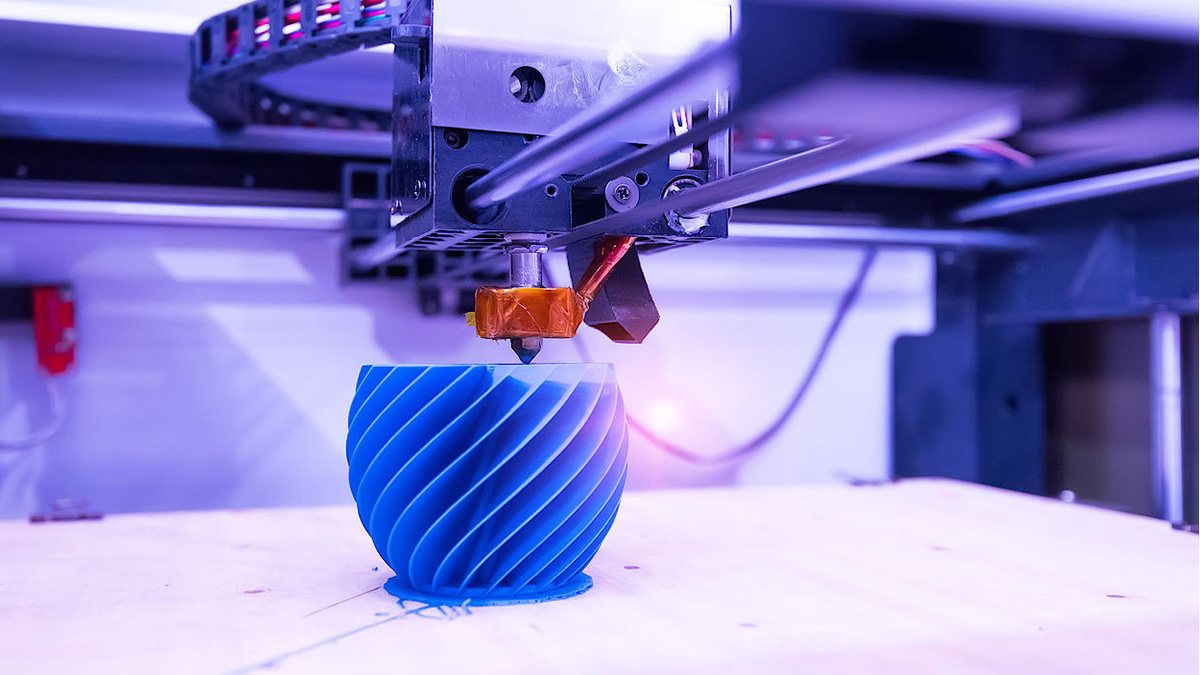

As the utilization of 3D printing expands across the broader spectrum of industrial manufacturing, the significance of this technology extends beyond its role as a rapid prototyping tool. This article provides an overview of the applications of 3D printing in the fabrication of molds and dies for processes such as injection molding and die casting.

2023-11-24 14:52:44

Defects are bound to arise during the reprocessing of mechanical equipment or parts related to metal. As a result, the final item's surface treatment process plays a crucial role, serving the dual purpose of enhancing aesthetics and providing protection. This process not only improves the performance of metal parts but also helps prevent rust.

2023-11-24 15:04:29

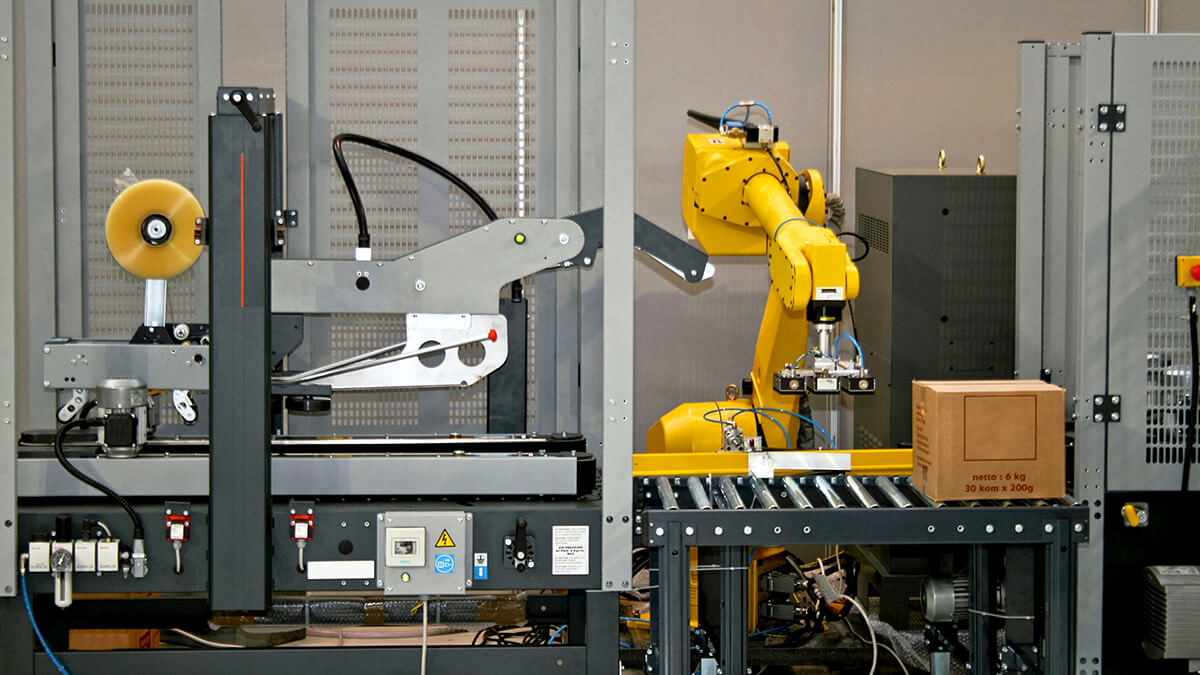

The integration of collaborative robots into production has become a pivotal element in the manufacturing chain, enhancing overall production efficiency. These compact collaborative industrial robots are designed to operate in confined spaces, addressing challenges posed by limited working spaces.

2023-11-24 15:13:23

Agree