- Showing results for

- Mold and Die

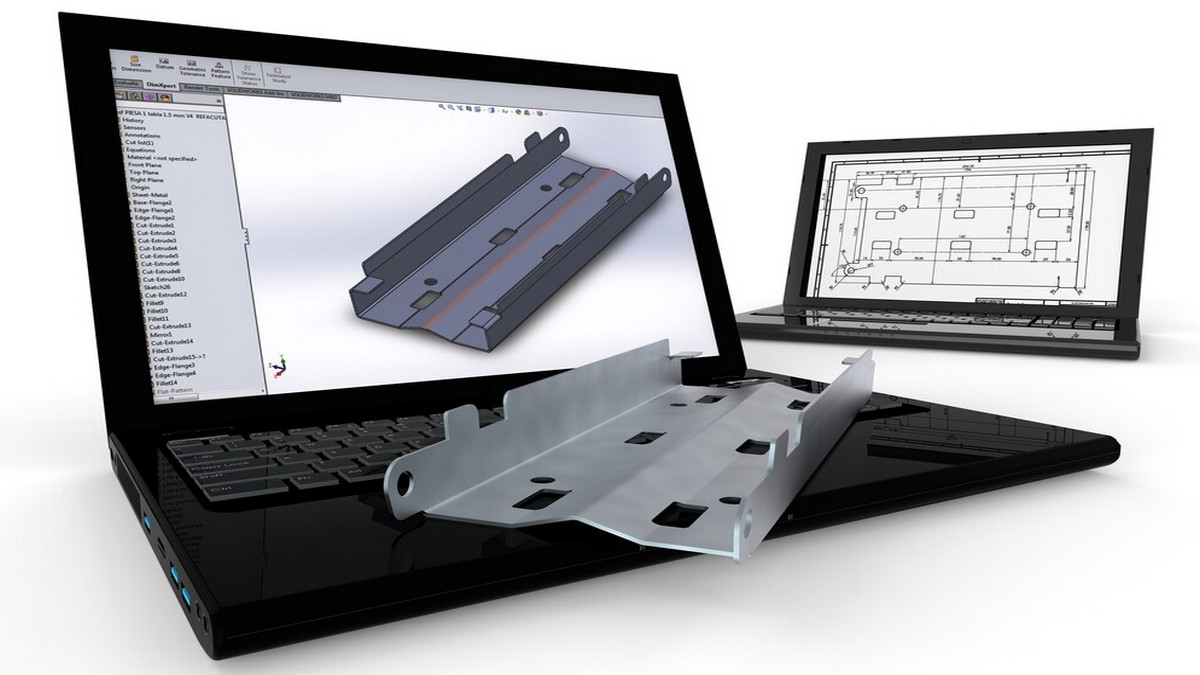

Are you familiar with the latest terminology related to Tooling 4.0? In this article, we'll offer an overview and examples that can help manufacturers understand and align with this evolving concept. Tooling 4.0 revolves around leveraging technology to transform 'inefficient' products into 'intelligent' ones.

2023-10-27 10:42:06

As adoption of 3D printing spreads throughout the larger sector of industrial manufacturing, the value of the technology as more than just a rapid prototyping tool is becoming increasingly evident. In this article, we gave an overview of how 3D printing is used to fabricate molds and dies for injection molding and die casting.

2023-05-23 10:46:04

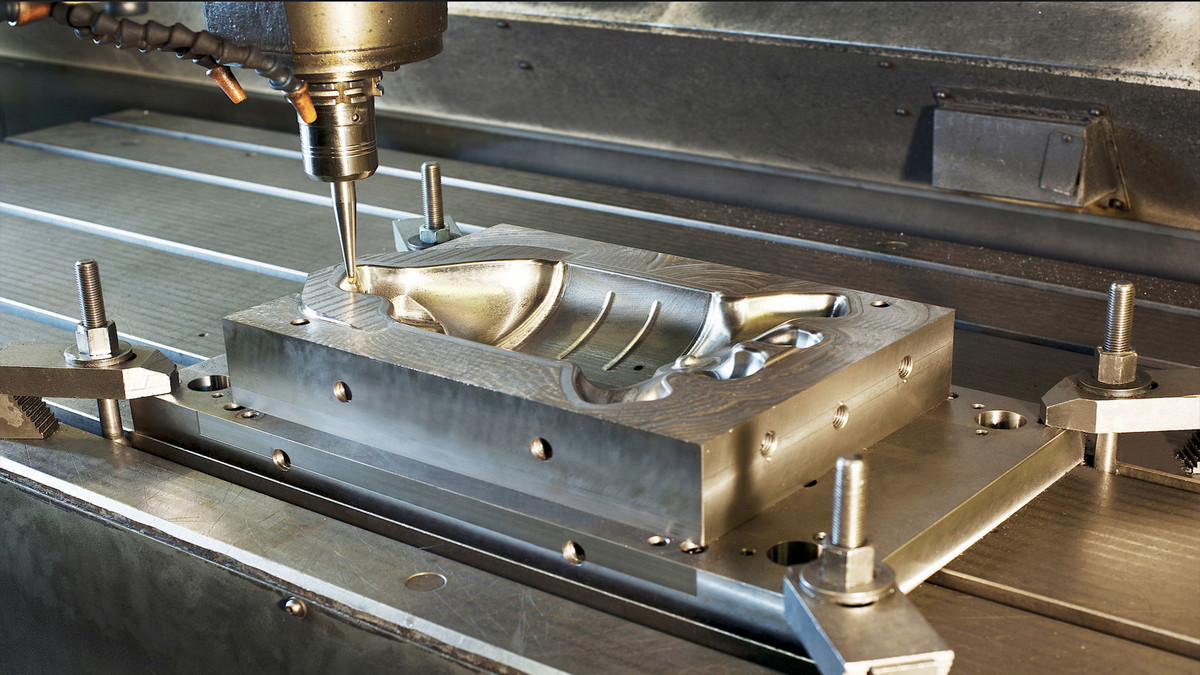

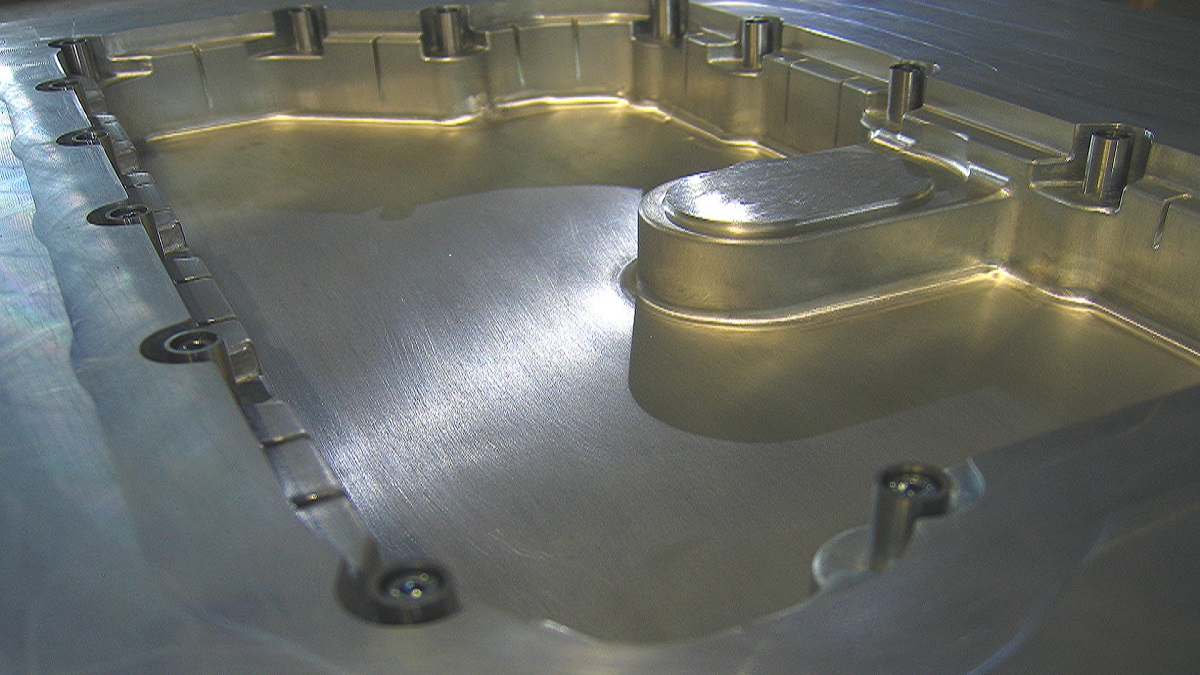

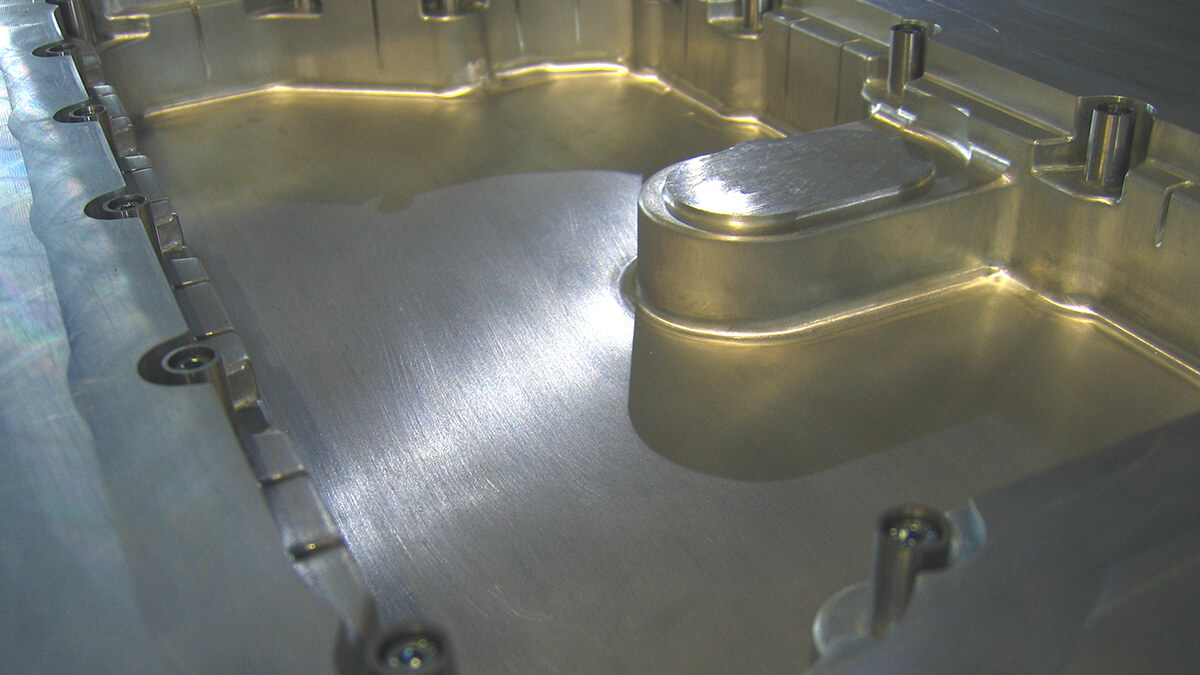

Die casting is a manufacturing process in which molten metal is injected into a mold cavity under high pressure and then cooled to form a part. It is often used for producing parts with complex shapes, intricate details, and thin walls. Die cast parts are usually made from metals such as aluminum, zinc, copper alloys, magnesium, lead or tin-based alloys.

2022-12-28 13:55:55

Molds are very important to the plastic injection industry. There may be hundreds of sets of molds in a factory, and molds in good condition must be used during production to ensure production quality. In order to be able to grasp the status of the mold at any time, how to manage the mold systematically? The two mechanisms of "Mold Common Modeling Mechanism" and "Mold Management Process" can be used to systematically grasp mold information and achieve the purpose of mold management.

2022-12-07 16:17:42

In recent years, customer orders and industrial demand have come and gone faster. Coupled with the impact of the epidemic, changes in orders are more difficult to grasp. At this time, what the manufacturing industry can control itself is all kinds of internal management. Only by doing a good job of management can we be able to respond to various changes at any time. From the perspective of mold management, what important information needs to be controlled?

2022-12-07 16:00:46

In aluminum, magnesium alloy die-casting molds, and gravity metal mold-casting molds, the design of the cooling system is also a key. The cooling system sometimes called the cooling pipe or the cooling circuit is composed of a series of high thermal conductivity materials. Its purpose is to take the heat away from the molten metal through direct heat conduction and realize the control of the mold temperature. Controlled, and directed cooling, to allow castings to cool as quickly as possible.

2022-12-06 10:12:31

Rapid molding technology is a fast, convenient, and practical mold manufacturing technology. It is especially suitable for the development and trial production of new products, process verification, and functional verification, as well as multi-variety and small batch production.

2022-08-18 10:50:15

Blanking is a punching piece used as a blank on the plate. Punching is punching round holes on the workpiece, and it can be performed simultaneously with blanking.

2022-08-17 10:39:24

A pair of molds is composed of an upper mold and a lower mold. The male die is a concave die, also known as the upper die. The design of the male mold is very important, and the structural characteristics of the female mold itself change with the structure of the product and the processing method of the mold, which is flexible.

2022-08-12 09:21:10

An injection mold is a tool for producing plastic products; it is also a tool for imparting complete structure and precise dimensions to plastic products. Because the production method is to inject the plastic melted at high temperature into the mold through high pressure and mechanical drive.

2022-08-08 10:51:59

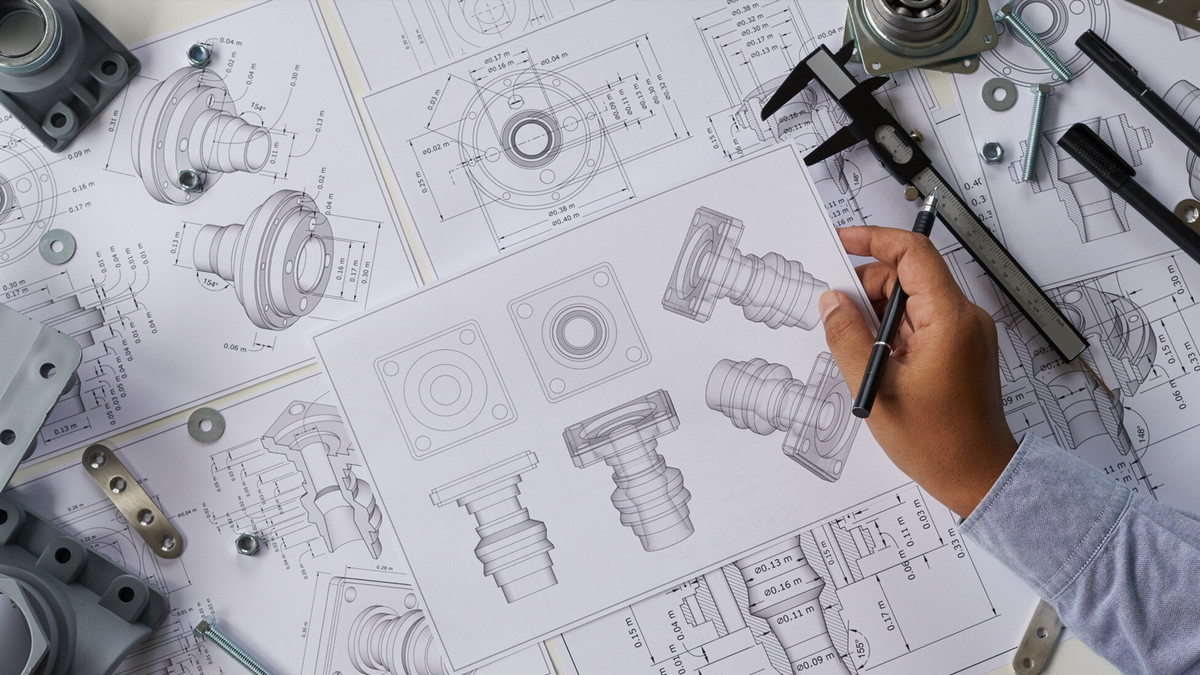

Nowadays, products have many functions and high complexity, so the requirements for the quality and precision of molds are becoming more and more stringent. Only through a complete evaluation and testing in the early mold development process can we produce mold products that customers are satisfied with.

2022-07-12 11:13:20

Quick Die Change (SMED), or 10-minute die change, is a set of useful techniques for dealing with multiple batches of small quantities and improving the rapid response capability of the production system and is a type of lean production method. The point is to convert internal jobs to external job conversions as much as possible.

2022-06-28 16:45:38

Fixtures and jugs are tools used to quickly fasten workpieces and guide tools during processing, so that the tooling machine, the tool, and the workpiece maintain the correct relative position. Jigs and fixtures are an indispensable part of machining tooling. Machine tool technology is constantly being driven in the direction of high speed, high efficiency, precision, compounding, intelligence, and environmental protection.

2022-06-14 11:41:17

Powder metallurgy uses metal powder as raw material, and forms it into a desired shape using a special processing technology. This processing technology is very similar to that used in the production of ceramics, so powder metallurgy techniques can also be used for the preparation and production of ceramic materials. This article will introduce the relevant technology of the powder metallurgy process in detail, and help the reader understand the advantages and disadvantages of the powder metallurgy process.

2022-06-06 15:45:26

Many people do not understand what a mold is. A mold (sometimes called a mould) is a block of material with a hollowed-out cavity that has a shape cut into sides of the cavity. Liquid or pliable material is pushed into the cavity where it adopts the shape of the hollowed out section. After the liquid hardens or sets inside the mold, or the pliable material has been pressed into the shape of the mold, the item is removed from the mold. Molds are made from a variety of materials, such as metal, clay, or wood, and can be used to form items out of many types of materials such as plastics or metals.

2022-05-24 13:57:56

A mold is a production tool that can produce parts with certain shape and size requirements. In industrial production, various presses and special tools installed on the press are used to make metal or non-metallic materials into parts or products of the desired shape through pressure. Such special tools are collectively referred to as molds.

2022-05-11 15:30:52

As the foundation of modern industry, mold technology has been widely used in automobile, energy, machinery and other fields.

2020-06-18 13:06:14

Die casting, or pressure casting, is a metal casting process characterized by the use of mold cavities to apply high pressure to the molten metal.

2020-05-22 10:12:47

Do you know the new words about tooling 4.0? Here we provide some introduction and example that manufacturers can know and follow the direction. Tooling 4.0 improves all about using technology to turn "clumsy" products into "smart" products.

2020-04-06 14:19:19

Agree