In the modern manufacturing era, where lightweight design and high performance are the top priorities, aluminum alloy forging has become one of the core processes across multiple industries. Whether in automotive, motorcycles, bicycles, aerospace, or industrial equipment, forged aluminum components are widely adopted due to their unique combination of light weight and high strength. For manufacturers, forging is not merely a processing method—it is a solution that ensures quality, efficiency, and reliability. Through precise material selection, professional process planning, and stringent quality control, companies can deliver high-performance products that meet international standards.

Fundamentals and Advantages of Aluminum Alloy Forging

Aluminum alloy forging involves the plastic deformation of aluminum alloys under high temperature, allowing the metal grains to realign and form a denser microstructure. This transformation enhances strength and durability while maintaining lightweight characteristics, making forged components ideal for applications that demand both high load-bearing capacity and long-term reliability.

Compared with casting, forged parts exhibit superior structural integrity, effectively avoiding casting defects such as porosity or shrinkage. Unlike machining, forging reduces material waste, improving cost efficiency. Today, forged aluminum alloys are extensively used in automobiles, aerospace, sporting goods, and industrial machinery, establishing themselves as the preferred manufacturing method for high-performance components.

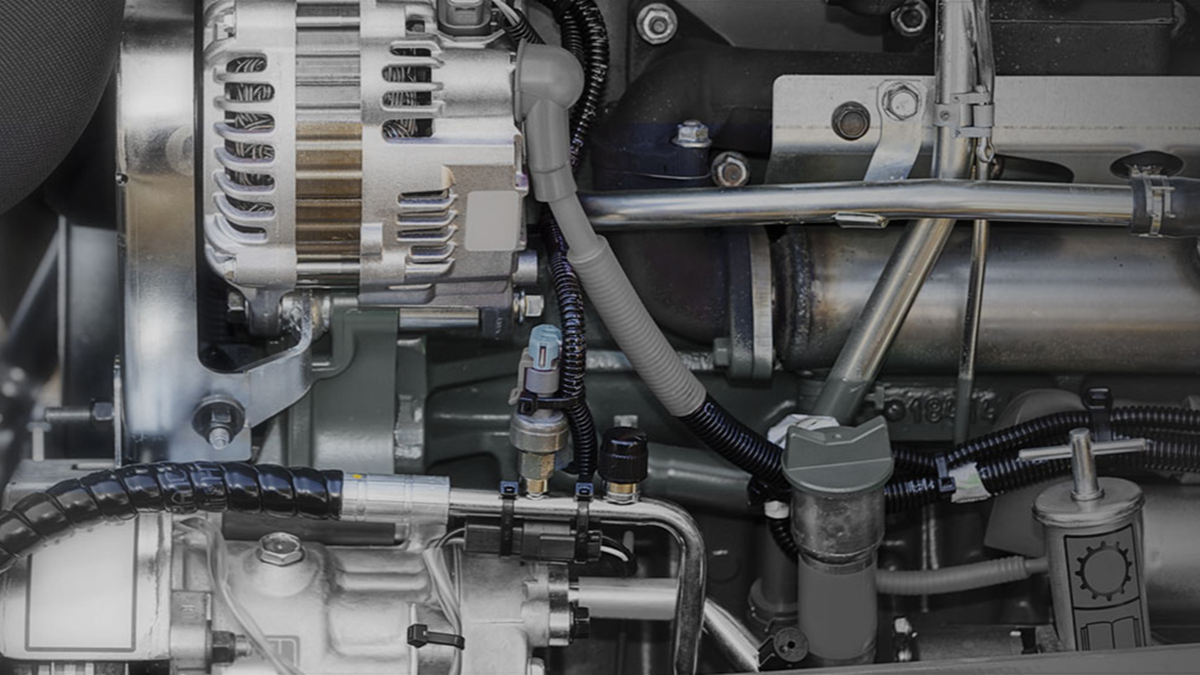

Another key advantage of aluminum forging lies in its excellent corrosion resistance and thermal conductivity. These properties make it suitable not only for structural parts but also for components requiring heat dissipation or environmental durability, such as brake systems, engine parts, and radiator components. For industries that demand high efficiency and reliability, aluminum alloy forging is undoubtedly one of the most effective solutions

Al Forge Tech’s Professional Processes and Technical Expertise

Al Forge Tech (AFT) has specialized in aluminum alloy forging for more than 30 years, providing design, manufacturing, and validation of high-performance, mission-critical components. With dual certifications in IATF 16949 and ISO 14001, the company demonstrates not only strict quality assurance but also a firm commitment to environmental responsibility.

AFT’s technical strength can be highlighted in three core areas:

- Tooling and Process Design:

By tailoring mold design and process planning to different industries and applications, AFT leverages computer-aided simulation and validation to predict the quality and deformation behavior of forged products in advance. This ensures dimensional accuracy, product consistency, and high production efficiency.

- Aluminum Heat Treatment Technology:

Heat treatment is the key to optimizing the mechanical properties of aluminum alloys. With decades of expertise, AFT precisely adjusts parameters based on material characteristics and application requirements. This enables forged parts to achieve the ideal balance of strength, ductility, and wear resistance—meeting the demands of harsh operating environments.

- Quality Control and Testing:

AFT has established a rigorous quality management process, covering raw material inspection, in-process monitoring, and final product testing. Using advanced methods such as optical inspection, non-destructive testing, and 3D measurement, AFT ensures every product meets international standards and customer expectations, earning the trust of clients worldwide.

Diverse Applications and Customized Services

Thanks to strong technical capabilities and flexible customization, AFT’s forged aluminum products are widely adopted in multiple industries. In the automotive and motorcycle sector, components such as brake calipers, pistons, control arms, and gear shifters deliver reliable performance under high temperature and heavy load conditions, ensuring driving safety.

In bicycles and sporting equipment, hubs, triple clamps, seat posts, and suspension parts combine lightweight design with high stiffness, offering athletes and consumers a superior experience. For industrial hardware and special applications, AFT’s forging solutions extend into aerospace, energy, and other demanding sectors, showcasing versatility and dependability.

AFT not only offers standardized products but also provides full-service solutions—from material selection and mold design to manufacturing and processing—ensuring each product is precisely tailored to its operating environment.

International Certifications and Market Positioning

To showcase its technical expertise and expand its global presence, AFT actively participates in international trade shows across automotive, bicycle, and industrial sectors. Through face-to-face engagement with global customers, the company demonstrates its advanced processes and innovative technologies.

AFT has earned IATF 16949 certification, confirming compliance with the highest standards of the automotive industry, as well as ISO 14001 certification, reflecting its commitment to environmental protection and sustainable development. These achievements not only serve as endorsements of product quality but also strengthen AFT’s professional reputation in the global market.

By combining international certifications with active global participation, Al Forge Tech has positioned itself as a trusted leader in aluminum forging—recognized for both technological expertise and environmental responsibility. Today, the company maintains long-term partnerships with renowned enterprises across Europe, Asia, and the Americas.

Conclusion

Aluminum forging plays an irreplaceable role in modern manufacturing. It is not only a means to enhance product performance but also a cornerstone for achieving lightweight and reliable designs. With over three decades of experience and international certifications, Al Forge Tech has successfully built a brand image of “high quality, sustainability, and reliability.”

Whether you are a manufacturer seeking high-performance components, a global brand looking for a reliable supplier, or an industry professional exploring advanced processes, AFT can provide comprehensive solutions and expert support. Looking ahead, as electric vehicles, green energy, and premium sporting markets continue to expand, aluminum forging will see even broader applications—and Al Forge Tech will continue to innovate and lead as a trusted partner in the industry.