In many high-precision machines, seemingly minor components often determine the overall performance. The Ballscrew Support Unit is a prime example of such a “critical small part.” This article uses SYK (Song Yang Industrial Co., Ltd.) as a reference to explain the function, design focus, manufacturing, and quality control of this component—and why a high-quality support unit can significantly enhance the performance of semiconductor equipment, CNC machines, medical instruments, and more.

SYK Overview and Core Advantages

SYK has long been engaged in the design and manufacturing of precision automation components, positioning itself as a leading manufacturer of precision automation equipment components. Its main product lines include Ballscrew Support Units, Transmission Support Units, Nut Supports, and Linear Guide / Slide Units. The company emphasizes short lead times for standard products (“3 days delivery”) and 100% inspection before shipment, reflecting SYK’s commitment to both timeliness and quality control.

The “Invisible but Performance-Defining” Role of Ballscrew Support Units

A ballscrew transmits linear motion through rotation and sliding, while the support unit fixes the screw end, bears axial and radial loads, and maintains axial clearance (or preload). It directly affects:

Positioning and Repeatability:

The rigidity and axial positioning error of the support unit amplify across the entire transmission system.

Vibration and Noise:

Improper installation or insufficient rigidity can increase vibration, reducing machining quality.

Lifetime and Reliability:

Material selection, bearing fit, and sealing design determine the lifespan of the ballscrew assembly and maintenance frequency.

In short, the support unit, though small, carries the three essential factors of precision, stability, and longevity, making it indispensable in precision machinery.

SYK Products and Technical Focus

According to SYK product specifications, support unit types are selected based on ballscrew precision grade (C3, C5, C7) and equipment load (light, medium, heavy). Key points include:

Grade Matching (C3 / C5 / C7):

Different precision grades require corresponding tolerance and fit in support units to maintain system positioning specifications.

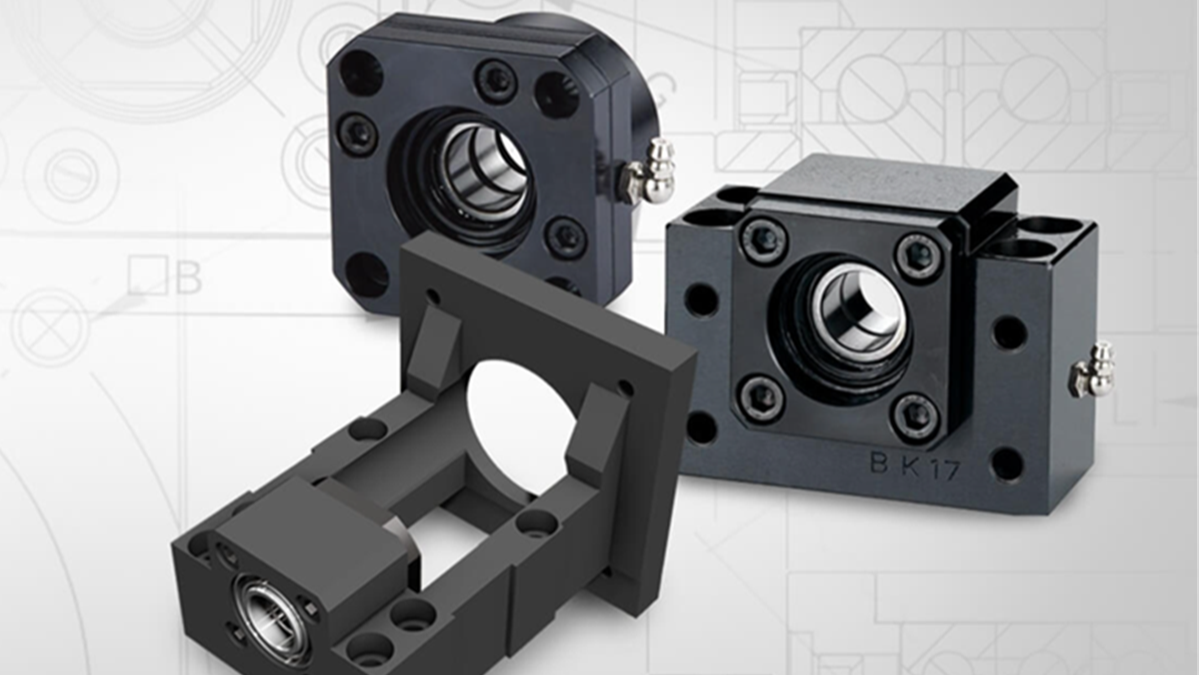

Variety of Models:

From general fixed side and support side units to heavy-duty fixed side units, covering applications from small-to-medium automation to large CNC machines.

100% Pre-shipment Inspection:

SYK performs full inspection of dimensional accuracy, coaxiality, friction, and rolling characteristics for all units.

Materials, Manufacturing, and Quality Control

To control micron-level positioning errors, design alone is insufficient—manufacturing and inspection processes must also be precise. SYK emphasizes ISO9001 Quality Management, with compliance to EU REACH / RoHS for materials and regulations. Critical processes include:

Precision Turning, Milling, and Grinding:

Ensuring seat holes, flange faces, and bearing fits meet strict dimensional and coaxiality requirements.

Heat Treatment and Surface Finishing:

Enhancing hardness and wear resistance, reducing clearance variation over time.

Precision Inspection Equipment:

Using CMMs, radial/axial clearance testing, dynamic balancing, and vibration analysis to guarantee batch consistency.

Industry Applications: Where SYK Support Units Work Their “Magic”

SYK support units are widely applied across high-precision industries:

Semiconductor Equipment:

Positioning accuracy and repeatability in wafer handling and processing directly affect yield and throughput. High-rigidity, low-wear support units reduce calibration frequency and downtime.

CNC Machines:

Rigid support units minimize tool vibration, improving surface finish and machining tolerance.

Medical and Precision Inspection Equipment:

Stable positioning and low vibration are critical for accurate diagnostics or treatments.

3D Printing and Automated Handling Systems:

Low wear and long life reduce maintenance costs for repetitive-motion equipment.

Ballscrew Support Units: Small Parts, Big Impact

In the world of precision industries, it is often the small yet highly accurate components that determine whether an entire system can operate with consistent performance. The ballscrew support unit is precisely such a critical element. Through rigorous design, precise manufacturing, and comprehensive inspection, SYK enables this seemingly inconspicuous part to carry the three essential factors of accuracy, stability, and longevity—becoming a solid foundation behind advanced applications in semiconductors, CNC machinery, and medical equipment.