In an era where electronic component manufacturing increasingly demands high precision and stability, the laser trimmer has evolved from a supplementary device into an indispensable core tool. Its introduction has fundamentally transformed the fabrication of resistors, sensors, and hybrid circuits, propelling the electronics industry toward micron-level precision and the future of smart manufacturing.

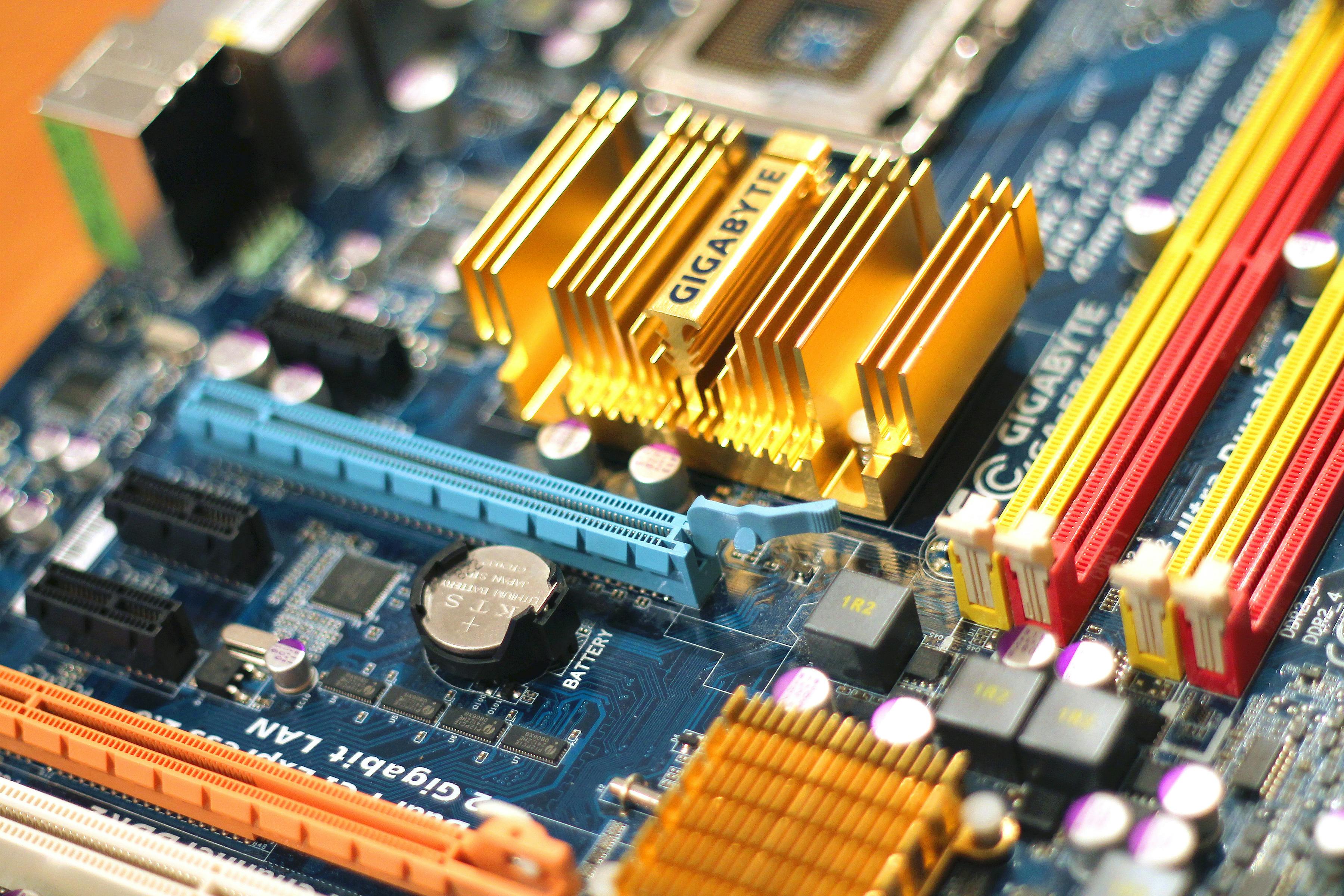

Photo by https://www.pexels.com/zh-tw/photo/technic-4316/

What is a Laser Trimmer?

A laser trimmer is a device that uses a high-energy laser beam to precisely etch or cut the surface of electronic components. Its primary purpose is to adjust the electrical characteristics of components—such as resistance, capacitance, or sensor sensitivity—to meet design specifications.

Why Has It Become Core to the Electronics Industry?

Precision Breakthrough: Micron-Level Control

Traditional mechanical adjustment methods struggle to achieve high precision, whereas laser trimming can control parameters at the micron or even nanometer level. For high-end resistors (e.g., ±0.1% tolerance) or precision sensors, laser trimming is the only viable mass-production solution.

Non-Contact Processing: Minimizing Damage

Laser processing requires no physical contact with the component, preventing mechanical stress and potential damage. It is especially suitable for handling fragile materials such as ceramic substrates and thin-film resistors.

Automated Integration: Enhancing Productivity and Consistency

Laser trimmers can be integrated with AOI (Automated Optical Inspection) and electrical testing equipment to form a closed-loop control system. This enables real-time adjustments and grading, improving both yield and efficiency.

Versatile Applications: Spanning Multiple Component Types

Applicable to thick-film resistors, thin-film sensors, hybrid ICs, and MEMS components, laser trimming is particularly critical in high-reliability fields such as automotive electronics, medical devices, and communication modules.

Technological Evolution and Future Trends

- AI-Assisted Trimming:Combining machine learning to predict optimal trimming parameters, boosting efficiency

- Multi-Wavelength Laser Technology:Capable of processing diverse materials, expanding application scope

- Smart Factory Integration:Laser trimmers serve as sensing and execution nodes within smart manufacturing systems

Conclusion

Laser trimmers are not merely precision processing tools—they are the gatekeepers of electronic component quality. They transform “tolerance” from a compromise into a precisely controllable parameter. As electronic products continue to demand higher reliability and precision, the role of laser trimming machines will only grow, cementing their status as a core enabler in the electronics industry.

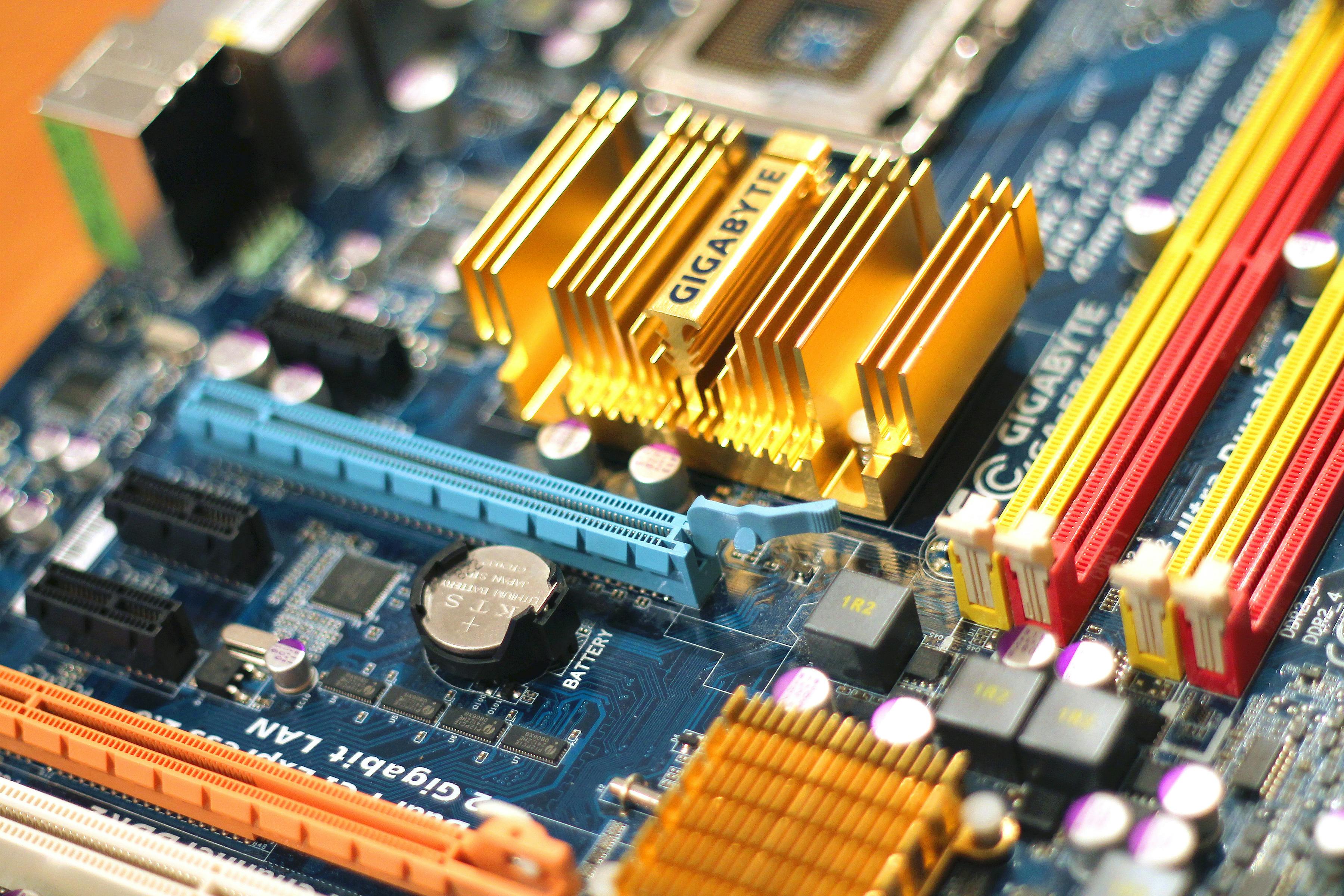

.jpg)