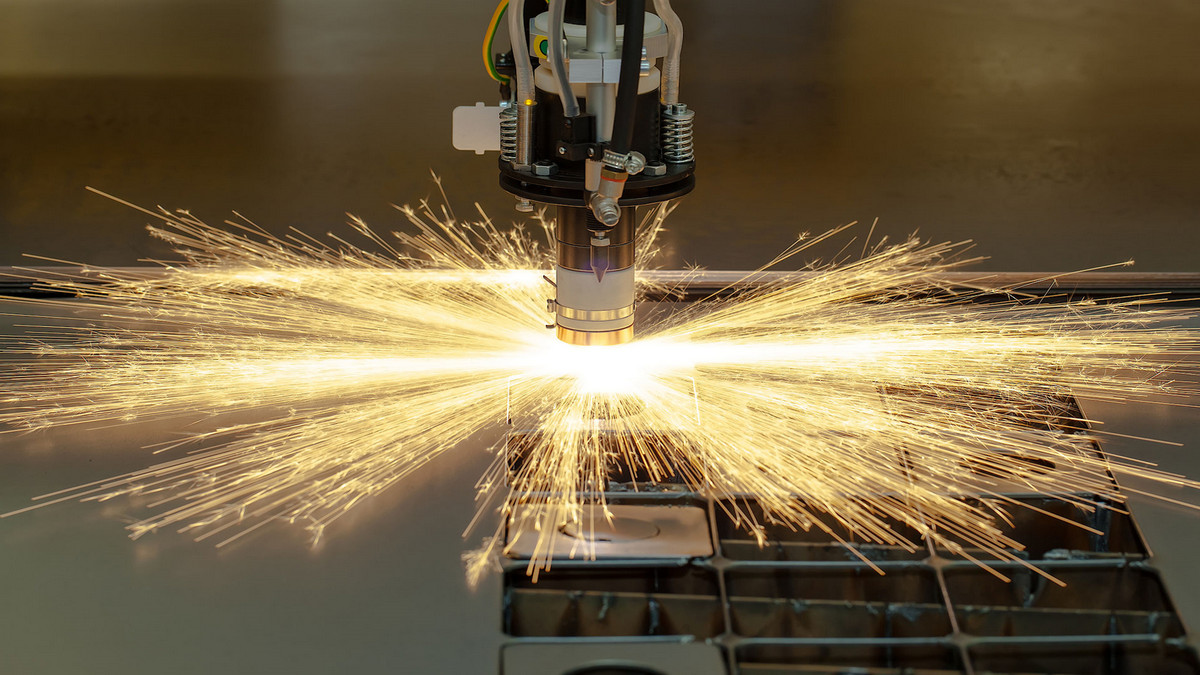

Lasers are used in a wide range of industries, especially in processing. The entire laser processing industry is currently moving in the direction of high power, ultra-short pulse, and intelligence.

Market Development of the Laser Processing Industry:

The laser industry is developing rapidly in the world, and now it has been widely used in laser intelligent manufacturing equipment, biomedical beauty, laser display, laser radar, high-speed optical communication, artificial intelligence, machine vision and sensing, 3D recognition, laser printing, scientific research, and other fields. Lasers are widely used in various industries, and some applications are gradually declining due to technological progress, such as the optical storage industry. However, most of the applications have been kept new for a long time, such as communication, medical beauty, national defense and military, instruments, etc., and even some new applications have been discovered with technological progress, such as for Light Detection and Ranging (LiDAR), Additive Manufacturing (AM), semiconductor Lithography equipment, etc. Especially in the application of processing, laser technology has unique characteristics, can be used for both additive and subtractive manufacturing, and is non-contact processing, so it occupies an important position in the manufacturing industry. Laser technology has unique characteristics, can be used for both additive and subtractive manufacturing, and is non-contact processing, so it occupies an important position in the manufacturing industry. The entire laser processing industry is moving in the direction of high power, ultra-short pulse, and intelligence.

With the development of global intelligence, the demand for lasers in smart devices, consumer electronics, new energy, and other fields continues to grow. As well as the continuous expansion of emerging applications such as medical and beauty equipment, the global market size of lasers will continue to maintain steady growth.

What is a Semiconductor Laser?

Semiconductor lasers, also known as laser diodes, are lasers that use semiconductor materials as working substances. Due to the difference in material structure, the specific process of different types of laser production is quite special. The commonly used working substances are GaAs, CdS, InP, ZnS, and so on. Semiconductor lasers have the best energy conversion efficiency among all types of lasers. On the one hand, they can be used as the core pump source of various optically pumped lasers such as fiber lasers and solid-state lasers. With the continuous breakthrough of semiconductor laser technology in power, efficiency, brightness, life, multi-wavelength, modulation rate, etc., semiconductor lasers are widely and directly used in material processing, medical treatment, optical communication, sensing, national defense, and other fields.

Optically exciting semiconductor laser technology uses high-power laser diodes as laser excitation light sources and then uses aluminum gallium indium arsenic semiconductor materials as gain media to generate lasers. This technology has been used in many applications since its development. It is emerging in the field, and it has changed the shortcoming of wavelength limitation in solid-state laser technology. In the optically excited semiconductor laser technology, the control and design of the semiconductor gain medium can generate near-infrared light wavelengths from 920nm to 1154nm, and then generate 355nm to 577nm by frequency doubling or triple frequency technology. Visible light wavelength. And these special wavelengths have been widely used in medical treatment, life science, and industry.

The Future Development Trend of Laser Processing:

Ultra-short pulse and high peak power are the future development trend of solid-state lasers, and are suitable for circuit board welding and cutting metal sheets. The higher the laser power, the faster the processing speed. Using diodes as excitation light sources can reduce the cost of ultrashort pulse lasers. In the macro processing part, the higher the power of the laser source, the higher the processing efficiency. In the micro processing part, the shorter the pulse, the smaller the heat zone on the workpiece, and the higher the machining accuracy. After sorting out the development trend of the global laser industry, it is concluded that the future development trend of laser processing will develop in the direction of a higher power, shorter pulse, and low price.

- High-power laser:

The efficiency of laser processing is closely related to the material of the workpiece itself, the wavelength of the laser light, the power of the laser light, and the pulse time. Improving the power of laser light has been the director of the industry's efforts, especially in macro processing, such as welding, cutting, cladding, etc., and laser power is also highly correlated with processing efficiency. Therefore, doubling the power can nearly double the efficiency and reduce the processing time by 50%, but the cost may only increase by 30%, which is attractive for the production line. The laser light power used in laser cutting has increased from 1KW to 8KW in the past few years, and some manufacturers have even exhibited 10KW, and the development of fiber laser sources for laser metal cutting to high power has become a trend. In the welding part, the 120KW laser is the product of the development trend of high-power lasers. The lasers used in national defense and military use can reach the level of 200KW, so the continuous development of higher power is the future trend of lasers.

From the perspective of the development trend of the entire high-power laser industry, fiber laser combines the waveguide characteristics of optical fibers and the integrated characteristics of semiconductors and has outstanding advantages such as good beam quality, high efficiency, good heat dissipation, compact structure, and flexible operation. It represents the development direction of high-power and high-brightness lasers. Another high-power laser trend is the use of Direct Diode Laser (DDL). The output power of a single laser diode varies from milliwatts to several watts, and the power can be increased by combining individual lasers into bar laser diodes and stacks of bar laser diodes. A standard laser diode stripe is 1 cm wide. Technological advances have enabled DDLs to generate output powers over 20 kilowatts in multimode systems at about 25% less cost than fiber lasers of the same power.

- Ultra-Short Pulse Laser (ULP):

One of the characteristics of an ultrashort pulse (USP) laser is that the pulse width is very short, which is a short laser light. In the field of laser technology, pulsed lasers with a time width between picosecond (ps), that is, 10-10s (1 ps=10-12s) to several femtoseconds (fs) (1 fs=10-15s) are generally called super short pulse laser. Ultrashort pulse laser is a general term for picosecond laser and femtosecond laser. Since ultrashort pulse lasers are widely used to detect ultrafast dynamic processes in the fields of science and engineering technology. Such as the excitation of electronic states in atoms, the dynamic response of materials and electronic devices, and the transient recording of various explosion shock waves, etc. The ultrashort pulse laser Pulsed lasers are also often referred to as ultrafast lasers.

The application of ultra-fast lasers in the industry is more inclined to precision machining. Since many precision components do not want thermal effects to affect product quality, ultra-short pulse laser processing can minimize thermal effects, so some industry players call it cold working. The components required by the electronic industry such as semiconductors and displays usually have high product quality requirements, but it is difficult to avoid thermal effects in other processing methods. Therefore, an ultrashort pulse laser is a good choice. The Industrial Internet of Things and electric cars require a large number of electronic components, including passive components, sensors, integrated circuits, power components, etc. Therefore, ultrashort pulse lasers are gradually gaining attention in the electronics industry and will be gradually adopted in the fields of automobiles, aerospace, biomedicine, and energy in the future, and the popularity of ultrashort pulse lasers will be just around the corner.

In addition to being used in lithography, lasers are suitable for processing semiconductor wafers. Whether it is cutting, marking, drilling, measuring, annealing, or removal processes, lasers are required to complete these semiconductor processes. Injection processing has relative advantages. In the future, with the trend of laser characteristics such as high power and ultra-short pulse, and the price of lasers will decline year by year, it will become popular, and many applications will continue to be discovered.