The manufacturing revolution in the micro world is quietly sweeping across the globe! As the medical, electronics, and automotive industries rapidly increase their demand for high-precision micro components, the global micromanufacturing equipment market is experiencing unprecedented growth. From implantable medical devices to smart car sensors, these precision tools not only drive technological innovation but have also become key investment targets for major international corporations and governments. With the support of intelligent and automated technologies, the future of micromanufacturing will be faster and smarter, propelling the global manufacturing industry to new heights!

With technological advancements driving a continuous rise in demand for micro components, the micromanufacturing equipment market is facing a rapid growth opportunity. According to market research reports, the global micromanufacturing equipment market size reached $27.7 billion in 2024 and is expected to grow to $48.6 billion by 2034, with a compound annual growth rate (CAGR) of approximately 5.9%. These machines are widely used in medical, electronics, and automotive sectors, primarily for producing high-performance micro parts—such as implantable medical devices, MEMS sensors, and advanced automotive sensors—to meet the strict precision and reliability requirements of high-end manufacturing. In developed countries around the world, innovation and application of high-precision micromanufacturing technologies are accelerating to keep pace with the urgent market demand for advanced manufacturing.

Market Growth Drivers

New technologies and policy support are the main drivers behind market growth. For example, the U.S. CHIPS and Science Act has invested $52.7 billion to revitalize the semiconductor and precision manufacturing industries, demonstrating strong government backing for domestic high-precision manufacturing. Meanwhile, sectors such as consumer electronics, medical devices, and automotive are moving toward extreme miniaturization and intelligent development, with expected compound annual growth rates of 8.5%, 9.1%, and 7.9%, respectively, in these submarkets. Additionally, the widespread adoption of electric vehicles, additive manufacturing technologies like 3D printing, and Industry 4.0-driven digital transformation further fuel the demand for lightweight, high-precision machining equipment.

Key Application Areas

- Medical Devices: Manufacturing micro surgical instruments, implantable devices, and in-body/out-of-body sensors used for precision healthcare and health monitoring. With growing demands for personalized medicine and remote monitoring, the micro medical device market is steadily expanding at an annual growth rate of about 9%.

- Electronic Products: Including semiconductor processing equipment, MEMS sensor components, and precision connectors used in smartphones, wearables, and IoT devices. The trend toward miniaturization in electronics continuously drives market demand for related manufacturing equipment.

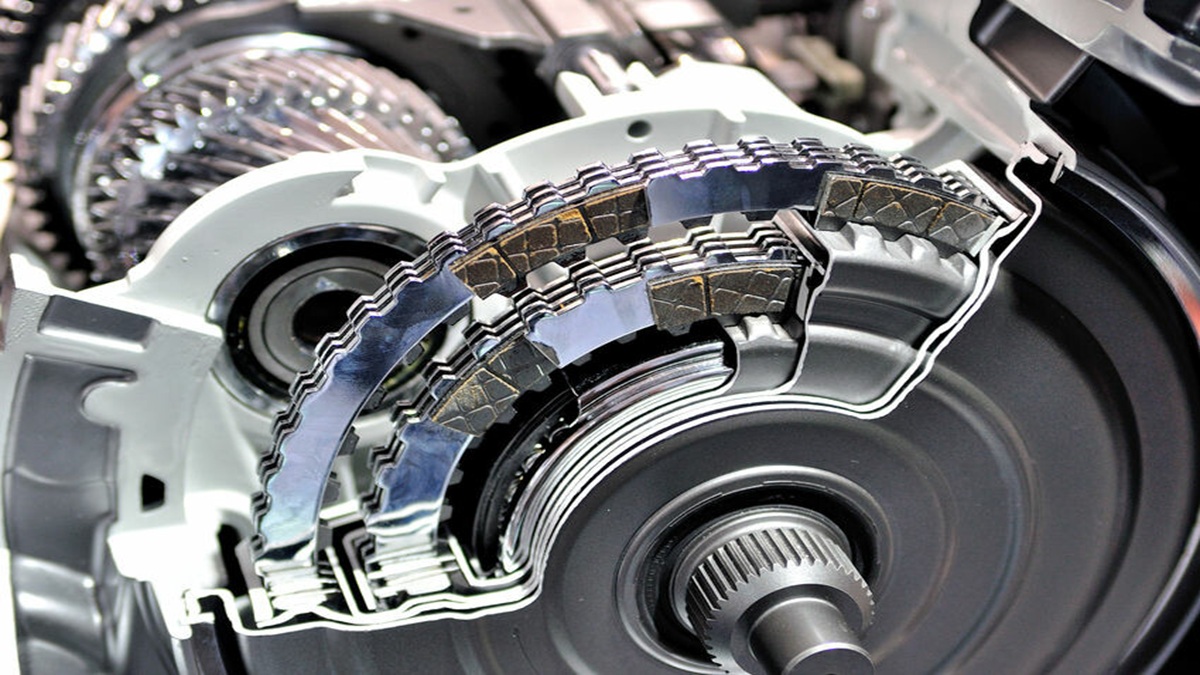

- Automotive Industry: Producing high-precision micro parts used in electric vehicles and autonomous driving systems, such as micro pumps, precision valves, and sensors. The rapid adoption of electrification and smart vehicle technologies further accelerates this growth trend, with an expected annual growth rate of around 7.9%.

Market Trends

The European and American markets are thriving under the dual drivers of policy and technology. The United States continues to increase investments in domestic advanced manufacturing—for example, the CHIPS and Science Act allocates substantial funds to support the semiconductor and precision manufacturing industries, aiming to attract corporate reshoring and upgrade R&D. In Europe, companies and governments collaborate to advance high-end manufacturing: the French-Italian joint venture STMicroelectronics invested $950 million to acquire part of the sensor business from the Dutch company NXP, strengthening its MEMS sensor product line for automotive and industrial sectors; meanwhile, Chinese chipmaker Nexperia is investing $200 million to expand its Hamburg, Germany facility to produce silicon carbide (SiC) and gallium nitride (GaN) power devices. These investment moves reflect the growing demand in Western markets for high-performance micromanufacturing technologies.

Future Outlook

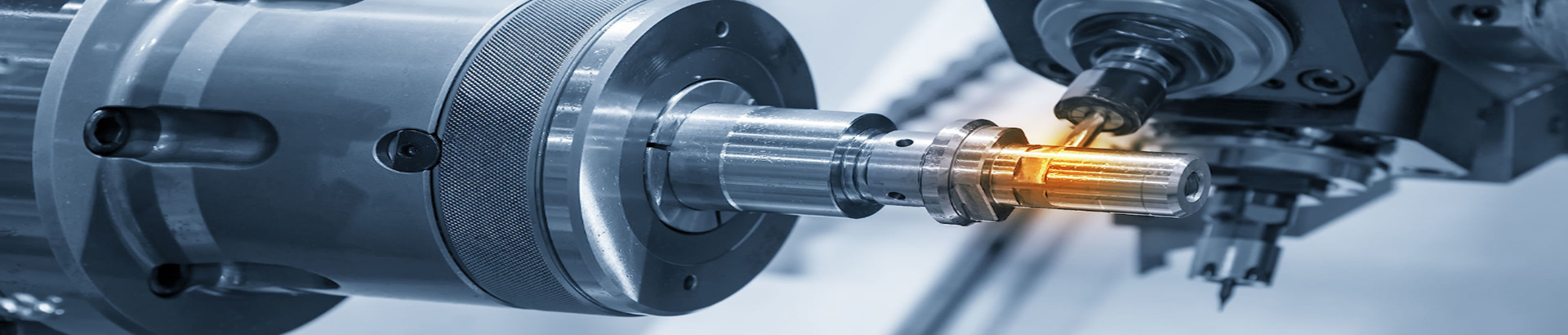

Looking ahead, micromanufacturing equipment will evolve toward greater intelligence and automation. Many current precision CNC machines have integrated Internet of Things (IoT) and big data analytics to enable real-time monitoring and predictive maintenance during manufacturing, further improving accuracy and production efficiency. Studies show that IoT-connected precision machining systems can boost capacity by about 30% while significantly enhancing quality control. Additionally, the application of new nano-composite materials and high-strength lightweight metal alloys will make manufacturing at micro- and even nano-scale possible, driving continuous breakthroughs in equipment performance and functionality. Overall, these technological advances will make micromanufacturing smarter, more flexible, and energy-efficient, effectively meeting the growing demand in European and American markets for high-value precision components and green manufacturing solutions.

.jpg)

.jpg)

.jpg)