In industrial packaging—particularly for chemicals, paints, and coatings—three-piece metal cans must endure extreme conditions: aggressive chemical formulations, internal pressurization, and long-term storage stability. Unlike beverage or food-grade containers, these applications demand superior corrosion resistance, leak-proof sealing, and structural robustness. Meeting these requirements starts not with the can itself, but with the can-making equipment that produces it. Manufacturers like Shin-I Machinery Works Co., Ltd. are rising to this challenge, offering specialized machinery designed explicitly for non-food, high-performance packaging. This article explores the critical design and production considerations for industrial three-piece cans, outlines key equipment selection criteria, and highlights leading global suppliers—including Shin-I—serving this demanding sector.

Manufacturers like Shin-I Machinery Works Co., Ltd. are rising to this challenge, offering specialized machinery designed explicitly for non-food, high-performance packaging. This article explores the critical design and production considerations for industrial three-piece cans, outlines key equipment selection criteria, and highlights leading global suppliers—including Shin-I—serving this demanding sector.

Why Industrial Three-Piece Cans Are Different

Three-piece cans consist of a body, bottom, and lid, typically joined by double-seam or welded joints. In chemical and paint applications, this architecture faces unique stresses:

- High corrosion potential: Solvents, acids, and alkaline compounds can degrade standard tinplate or aluminum.

- Internal pressure: Aerosol paints or pressurized cleaners may require cans to withstand 1.5–3 bar without bulging or leaking.

- Seal integrity over time: A micro-leak can lead to product degradation, safety hazards, or environmental violations.

To address these, manufacturers apply epoxy-phenolic or polyester-based internal coatings, use thicker gauge substrates, and implement precision-controlled seaming. Crucially, the production equipment must preserve coating integrity during forming, flanging, and seaming—without introducing contamination or mechanical stress.

Key production considerations include:

- Use of non-marring tooling to avoid damaging internal linings

- Welding or seaming heads calibrated for high-tolerance, repeatable closure

- Corrosion-resistant machine components (e.g., stainless steel frames, sealed bearings)

- Integration of in-line inspection systems for seam tightness and coating continuity

Failure at any stage risks can failure in the field, regulatory non-compliance, or costly recalls—especially under tightening global regulations like the EU’s Packaging and Packaging Waste Regulation (PPWR).

How to Choose the Right Can-Making Equipment for Industrial Applications

When sourcing machinery for chemical or paint cans, speed alone is insufficient. The following criteria are essential:

| Selection Factor |

Why It Matters |

| Compatibility with Coated Substrates |

Equipment must handle pre-coated metal without scratching or delaminating protective layers. |

| High-Precision Seaming |

Tight tolerances ensure hermetic seals that withstand pressure cycling and thermal variation. |

| Corrosion-Resistant Construction |

Machine frames, rollers, and contact parts should resist chemical exposure in production environments. |

| Customization Flexibility |

Ability to produce varied diameters, heights, and specialized openings (e.g., paint pour spouts). |

| Automation & Quality Control |

Integrated vision systems or pressure testers enable real-time defect detection and traceability. |

Investing in purpose-built equipment reduces waste, improves compliance, and supports sustainability through longer machine life and fewer defective units.

Top 5 Can-Making Equipment Suppliers for Industrial (Non-Food) Applications

While many vendors focus on beverage cans, the following five companies offer proven capabilities in high-corrosion, high-pressure three-piece can production—including for chemical drums, paint buckets, and aerosol containers.

| Company |

Headquarters |

Key Strengths |

Website |

| Shin-I Machinery |

Taiwan |

60+ years of experience; ISO 9001 & CE certified; specializes in custom three-piece can lines for chemicals, paint, and aerosols; corrosion-resistant designs with advanced sealing tech; serves 70+ countries. |

www.shinican.com |

| Sacmi Imola S.C. |

Italy |

Global packaging leader; offers end-to-end metal can lines with high-precision welding and seaming; strong in European industrial packaging; emphasizes sustainability and automation. |

www.sacmi.com |

| KHS GmbH |

Germany |

Part of Salzgitter Group; known for robust can bodymakers and seaming units; serves non-beverage sectors including industrial fluids and specialty chemicals; integrates Industry 4.0 solutions. |

www.khs.com |

| Shengxin Industrial Co., Ltd. |

Taiwan |

35+ years in can machinery; expertise in necking, flanging, and seaming for both two- and three-piece cans; reliable for paint and chemical packaging in Asia-Pacific. |

www.shengxin.com.tw |

| Zhejiang Longwen Precision Equipment |

China |

Publicly listed (NEEQ); provides fully automatic metal can lines; serves diversified markets with scalable, high-output systems. |

www.longwengroup.com |

Note: While Sacmi and KHS are better known for beverage lines, both have documented deployments in industrial packaging, particularly in Europe where chemical compatibility and recyclability are regulated stringently. Shin-I Machinery, by contrast, has built its reputation specifically on non-food, high-demand applications, including high-pressure aerosol and chemical can equipment.

The Road Ahead: Innovation Meets Compliance

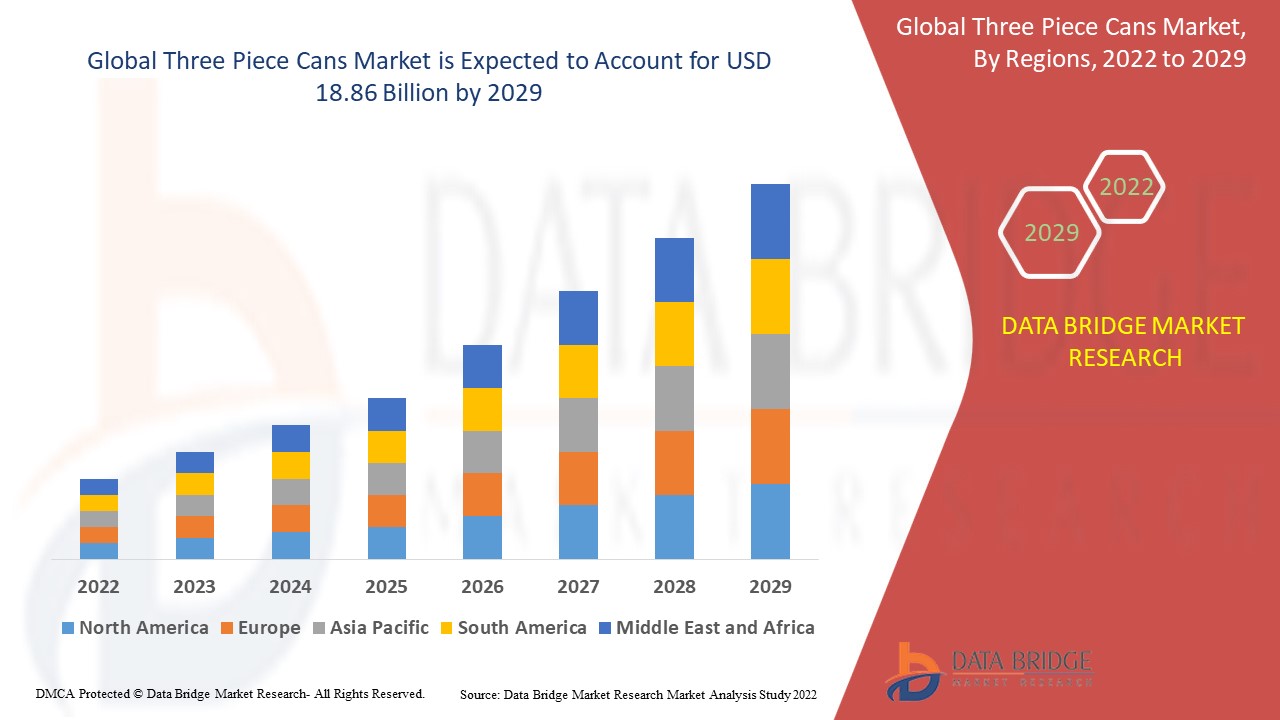

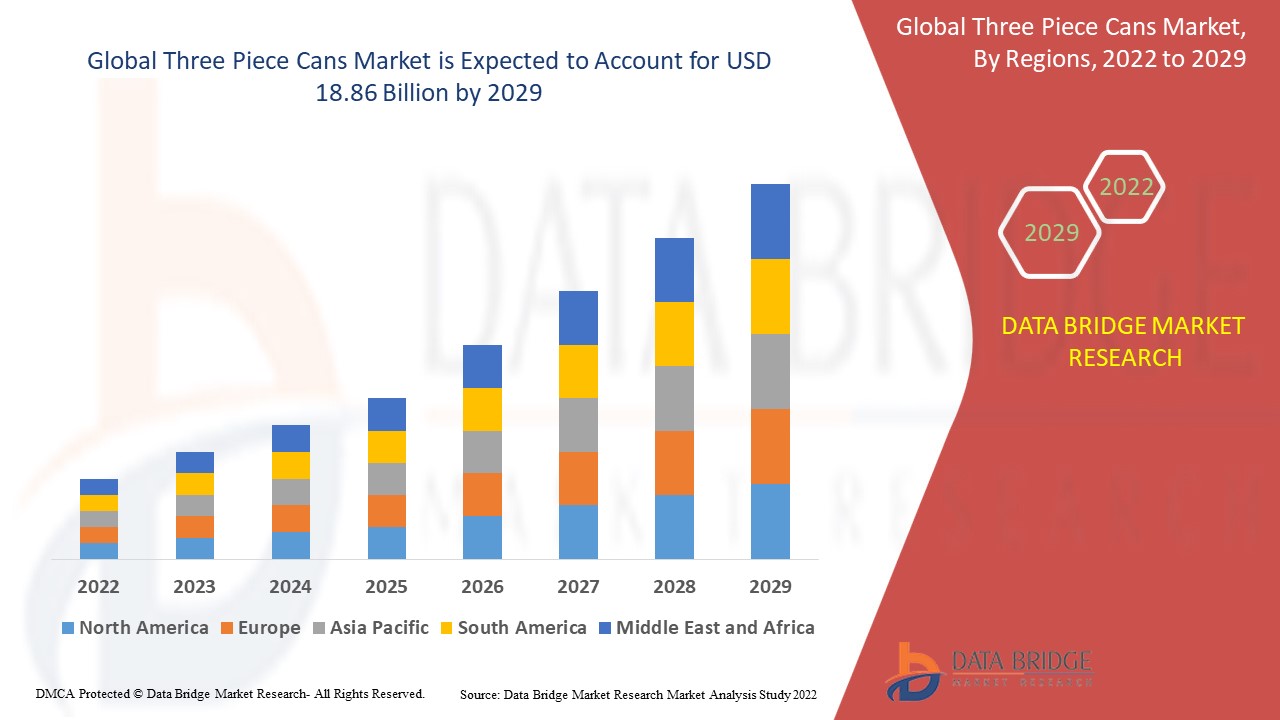

The global three-piece can market is projected to grow from $33.8 billion in 2025 to $44.9 billion by 2030 (CAGR: 5.82%), driven not only by beverages but also by industrial and chemical packaging demand—especially in North America, Europe, and Asia.

As environmental regulations tighten and end-users demand safer, more durable packaging, the role of specialized can-making equipment becomes ever more critical. Companies that invest in corrosion-resistant materials, precision sealing, and smart automation will lead this transition.

With its six-decade legacy, global footprint, and focus on high-pressure, high-corrosion solutions, Shin-I Machinery exemplifies how equipment manufacturers can turn technical challenges into competitive advantages—ensuring that every can, whether holding paint or industrial solvent, performs safely and reliably.

References

- MarketsandMarkets. (2024). 3-Piece Metal Cans Market Size & Share Analysis – Global Forecast to 2030.

https://www.marketsandmarkets.com/Market-Reports/three-piece-metal-cans-market-288790733.html

- DataBridge. (2022). Global Three Piece Cans Market – Industry Trends and Forecast to 2029.

https://www.databridgemarketresearch.com/reports/global-three-piece-cans-market)

- European Commission. (2023). Proposal for a Regulation on Packaging and Packaging Waste (PPWR).

https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en

- NACE International. Corrosion Prevention in Food and Chemical Processing Facilities.

https://www.nace.org/resources/technical-resources/corrosion-basics

- Shin-I Machinery Works Co., Ltd. – Official Website & Product Catalog.

https://www.shinican.com

- Smithers. (2023). Metal Cans Industry Research, Trends | Data Book, 2023–2030.

https://www.smithers.com/services/market-reports/package-converting/metal-cans-market-report

- Sacmi Group. Metal Packaging Solutions – Can Bodymakers & Seaming Lines.

https://www.sacmi.com/en/metal-packaging

- KHS GmbH. Can Line Solutions for Industrial & Specialty Applications.

https://www.khs.com/en/products/can-lines/

- Packaging Digest. (2022). The Ultimate Comparison of 3-Piece Can Types and Their Applications.

https://www.packagingdigest.com/metal-packaging/comparing-3-piece-can-designs-for-industrial-use

- U.S. Food and Drug Administration (FDA). (2021). Current Good Manufacturing Practice (CGMP) for Food Equipment.

https://www.fda.gov/food/guidance-regulation-food-and-dietary-supplements/current-good-manufacturing-practice-cgmp-food

- ResearchGate. (2023). Shallow Review of Sealing Technology in Chemical Equipment.

https://www.researchgate.net/publication/368921452_Shallow_Review_of_Sealing_Technology_in_Chemical_Equipment

- Occupational Safety and Health Administration (OSHA). Technical Manual – Chemical Handling in Industrial Packaging.

https://www.osha.gov/otm

.jpg)

.jpg)

.jpg)