As technology advances, the design philosophy behind modern passenger aircraft is undergoing a profound transformation. The evolution of aircraft materials is no longer just about reducing weight; it's a comprehensive revolution encompassing intelligence, safety, and sustainability. From groundbreaking composites to self-diagnosing smart sensors and manufacturing techniques built on a circular economy, future aircraft won't just be cold machines. They’ll be intelligent, self-aware, safer, and more eco-friendly flying bodies.

Lightweighting: Why Carbon Fiber & Aluminum Are Essential for Modern Airplanes

To achieve higher fuel efficiency and performance, reducing aircraft weight is the top priority.

Carbon Fiber Reinforced Polymer (CFRP) : Modern airliners like the Boeing 787 and Airbus A350 use CFRP for over 50% of their structural weight. Compared to traditional aluminum, CFRP can reduce weight by roughly 20%, boosting fuel efficiency by 10-20% or even more. Its high strength-to-weight ratio, stiffness, and corrosion resistance make CFRP the material of choice for lightweighting.

Aluminum-Lithium Alloys (Al-Li) : As the new go-to material for next-gen aircraft skins and wing boxes, Al-Li alloys significantly enhance specific strength, fatigue resistance, and corrosion performance by adding 1-3% of lithium. New alloys like the 7075 series and 2xxx series (e.g., AA2198) are now widely used for fuselage skins, offering substantial weight savings while maintaining excellent strength.

Titanium Alloys (Ti-Alloys) : Titanium alloys boast an exceptional strength-to-weight ratio, superior corrosion resistance, and high-temperature performance, making them ideal for high-stress areas like fuselage frames, landing gear, and engine pylons. Although more expensive, their reliability and low maintenance requirements are irreplaceable in high-load, high-temperature environments.

Smart Materials: The Tech That's Giving Aircraft a Sixth Sense

Future aircraft won't passively wait for maintenance; they'll actively monitor their own condition.

Structural Health Monitoring (SHM) Sensors : Integrating sensors into an aircraft's structure enables real-time smart management. Fiber Bragg Grating (FBG) sensors are increasingly common in airframes due to their small size, resistance to electromagnetic interference, and ability to be distributed widely. These sensors can monitor structural stress, vibration, and temperature in real time. Some materials can even self-sense damage: embedded piezoelectric or conductive materials generate electrical signals under stress, detecting micro-cracks and providing early warnings for preventative maintenance.

Self-Healing Materials : New polymer-based composites feature microcapsules or reversible bonding systems that can autonomously repair tiny cracks as they form. When the material is damaged, the capsules rupture, releasing a healing agent that reacts with the base material to seal the crack. This technology can significantly extend component life and reduce maintenance costs.

Safety First: The Latest in Damage Tolerance & Fire-Retardant Design

Ensuring aircraft safety under extreme conditions requires materials with superior toughness and resilience.

Composite Damage Tolerance : To improve impact and fatigue resistance, new composites use multi-directional fiber weaving and toughening resins to enhance interlaminar fracture toughness and suppress crack growth. Materials like GLARE (Glass Laminate Aluminum Reinforced Epoxy) combine the ductility of metal with the high strength of fibers, drastically improving damage tolerance and crack resistance in structural parts.

Fire-Retardant & Low-Toxicity Interiors : To mitigate fire risks, cabin interior materials must meet strict fire standards like FAA FAR 25.853. Seats, carpets, and partitions are made from highly fire-retardant polymers or composites with additives that produce minimal smoke and low toxicity gases when burned.

Sustainability: How Aviation Is Embracing a Greener Future

The aerospace manufacturing industry is actively embracing a circular economy and manufacturing innovation to create a more eco-friendly production model.

Composite Recycling : As more CFRP aircraft are retired, recycling technology is becoming crucial. Pyrolysis can break down the resin in a low-oxygen environment (350–700°C), recovering carbon fibers with only 10-50% of the energy needed to produce virgin fibers. Meanwhile, thermoplastic composites can be mechanically shredded and re-melted, offering high recyclability.

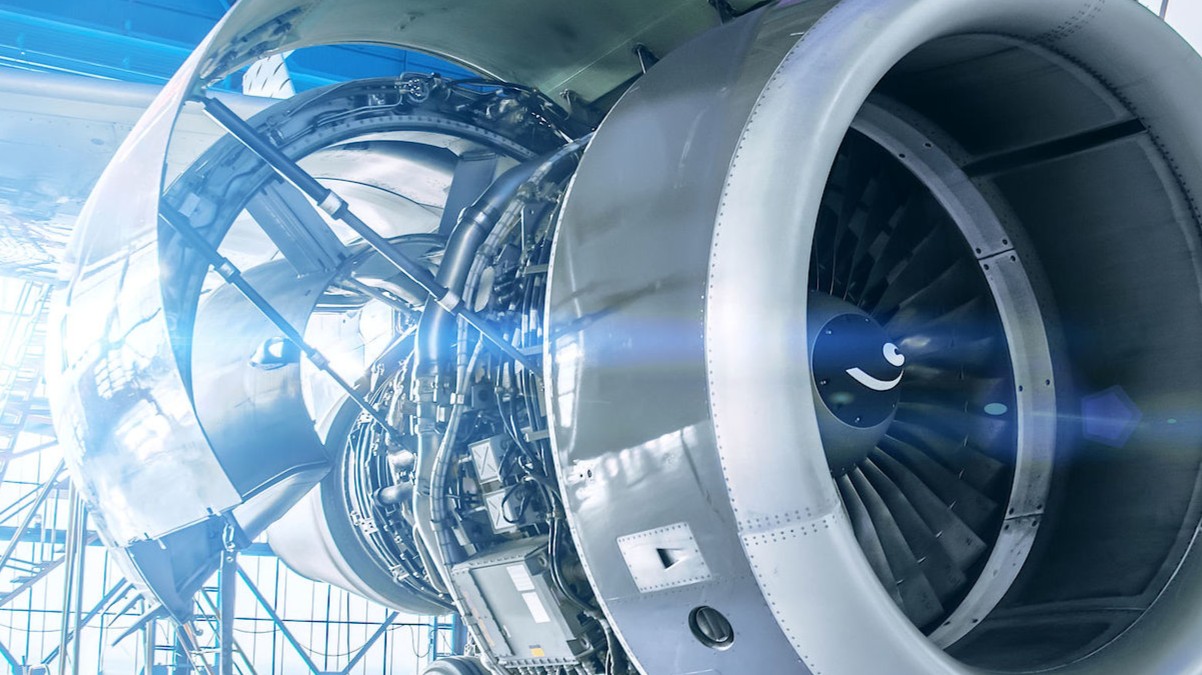

Additive Manufacturing (3D Printing) : Metal and composite 3D printing are gaining momentum in aerospace. For example, CFM LEAP engine fuel nozzles made via 3D printing consolidate 20 parts into a single unit and reduce weight by around 25%. This technology enables topology optimization, fewer parts, and shorter lead times, expanding its use in structural components, engine parts, and cabin interiors.

Extreme Environments: The Materials Built for Hypersonic Flight

For hypersonic flight and high-temperature engine environments, materials need extraordinary heat resistance.

Ultra-High-Temperature Ceramics (UHTC) : Hypersonic vehicles and re-entry spacecraft require materials that can withstand temperatures over 2000°C. Zirconium-based or hafnium-carbide UHTCs have melting points between 3200-3900°C, making them critical for components like wing leading edges and nose cones that face intense aerodynamic heating.

Thermal Protection Systems (TPS) : Heat shields on re-entry vehicles use advanced fiber-reinforced ceramic composites, such as carbon/carbon materials, to block temperatures exceeding 2000°C. Simultaneously, aircraft engine turbine blades and nozzles use nickel-based or γ-TiAl high-temperature alloys, designed to handle extreme stress and temperatures up to 800-1200°C.

Future aircraft will no longer be built from a single material but rather from a synergistic blend of advanced materials. From lightweight CFRP and self-diagnosing smart materials to sustainable recycling technologies, aircraft manufacturing is moving into a new era of efficiency, safety, sustainability, and intelligence. This materials revolution not only boosts flight performance but also lays a solid foundation for the long-term, sustainable development of the aviation industry.

.jpg)