The revenue of the laser industry grows higher and higher in recent years. As manufacturing industry moves toward smart, intelligence and systematization, the laser manufacturing process has become an indispensable role in the manufacturing industry.

Laser industry moves toward smart, intelligence and systematization

The key module in the laser processing equipment is a laser source, which takes up approximately one-third in the equipment cost structure; laser source is also a crucial factor in the processing results. The lasers sources develop rapidly, and with the demand from the industry, various types of lasers appear, and the upstream ecological-chain of the laser industry also began to shape.

From the perspective of market size alone, the scale of the laser industry is somewhat insignificant compared with the scale of its application industries such as optoelectronic semiconductors and metal processing. However, the application of laser technology can cover various fields, from automobiles, monitors, mobile phones, aerospace, medical equipment to national defense and military, food packaging, etc., we can think of industries that have laser applications. Therefore, for the manufacturing of many industries, the manufacturing industry policy of laser itself, the core of these policies is smart manufacturing, and one of the cores of smart manufacturing is optoelectronic technology, and one of the cores of optoelectronic technology is the laser.

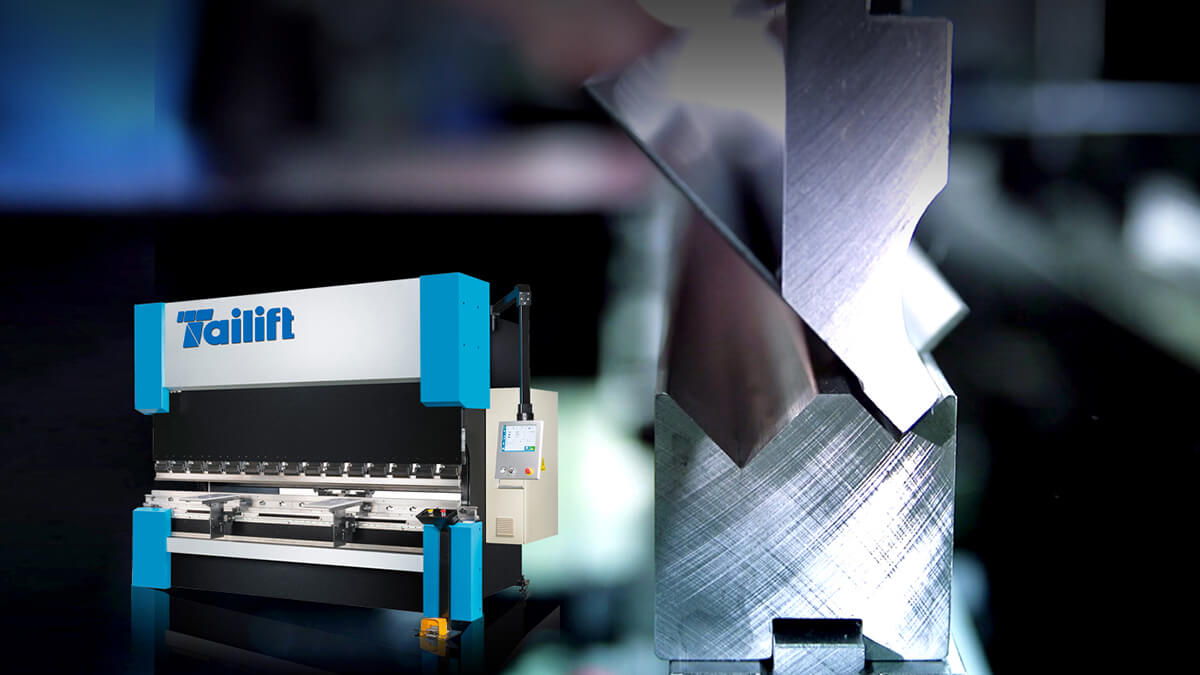

Tailift Group invest in the fiber laser industry, position itself as a value device

In addition to the optical communications market, currently, the largest material processing is the laser application market. In the future, as the manufacturing industry continues to develop, the material processing market can be divided into high-power processing and micro-processing. In order to meet the production needs of laser cutting machines, laser cutting machines, and other laser application equipment, Tailift Group has been recognized by the international market since its stride in sheet metal equipment in 1989, and it is more stable in the field of computer punching machines. The domestic market ranks first. In view of the fact that laser cutting has gradually become mainstream, the fiber laser cutting machine equipped with a FANUC controller was released in 2016, and its excellent performance was achieved. In 2018, it achieved a sales of 100 units and became the largest fiber-optic laser equipment manufacturer in Taiwan.

Due to the characteristics of high precision, high production efficiency, low pollution, and digitization, the laser is very suitable for high-value industrial applications and promotes the rapid development of the automotive and 5G industries towards smart manufacturing. The cost of materials and equipment has decreased year by year. Many laser cutting equipment enter the market at low prices, but the life cycle of the equipment is short, and the manufacturers pay relatively higher purchase costs.

Tailift Group has more than 45 years of experience in the design and production of machine tools and applies the rigid design of heavy-duty machine tools to the development of laser cutting machines. It not only has a high-rigidity body but also has a solid assembly technology to ensure that the machine is long. Time usage still maintains the best condition, effectively improving the customer's competitive advantage, which is also the main reason why the company's products can quickly sweep the market.