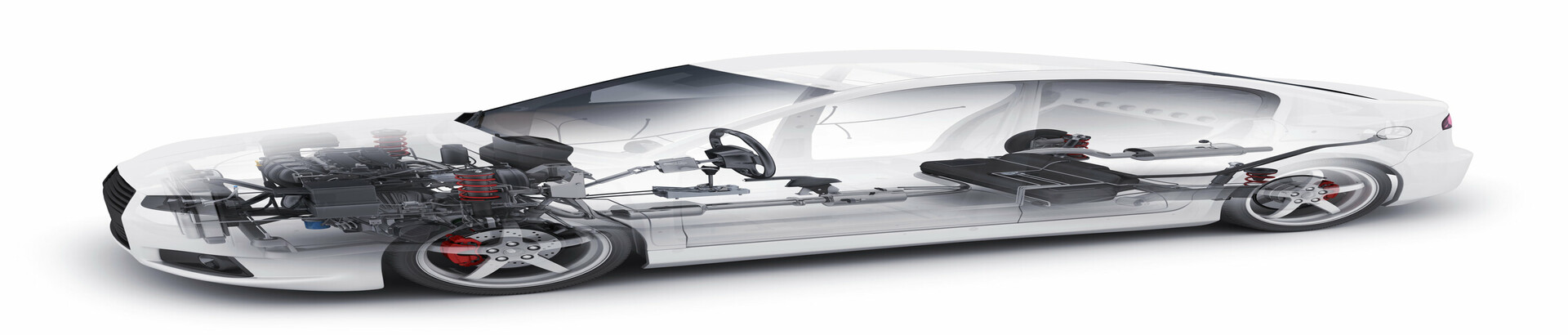

When you drive an electric vehicle, the first thing that might surprise you is the astonishing quietness and linear acceleration. There’s no gear-shifting jolt, no roar of a traditional engine—just a seamless connection between you and the car. Yet you might wonder: without a gearbox, how does an electric vehicle transmit power to the wheels? This is one of the key breakthroughs in EV design, simplifying the structure while redefining what “smooth” and “efficient” driving really feels like.

The Beauty of Direct Electric Power

Traditional internal combustion engines require gearboxes because the engine only operates efficiently within a specific RPM range. By changing gear ratios, the gearbox keeps the engine in its optimal efficiency zone at different speeds—but every gear shift introduces a brief interruption and a slight jolt, what we call “shifting.”

Electric motors, however, behave entirely differently. From the moment they start, they deliver impressive torque and maintain high efficiency across an extremely wide RPM range. This eliminates the need for a gearbox to “match” speeds, allowing the motor to drive the wheels directly. This is why EVs feel so smooth: no shifting interruptions, only pure, direct power delivery.

Precision Manufacturing of the Single-Speed Reduction Gear

Even without a traditional gearbox, EVs still require a reduction gear set, known as a single-speed reduction unit. Its role is to lower motor speed while amplifying torque to handle different driving conditions.

Although it seems like a simple “single gear set,” the manufacturing precision required is even higher. Unlike complex multi-gear transmissions in conventional cars, EV reduction gears must achieve micron-level tolerances. Even the slightest deviation can cause noise or vibration, directly affecting the vehicle’s quietness. Moreover, due to the high torque and speed, gear materials, heat treatment, and meshing design must be carefully engineered and manufactured to ensure durability and transmission efficiency.

This is where CNC machines truly shine. From precision cutting of gears and drilling of holes to one-piece housing manufacturing, CNC machines ensure every component meets exact dimensional and geometric requirements. This allows the single-speed reduction unit to operate with maximum efficiency and near-silent performance.

Conclusion

The rise of electric vehicles is shifting the automotive industry’s focus from “how to burn fuel more efficiently” to “how to transmit electrical energy more effectively.” In this technological revolution, precision single-speed reduction gears play a crucial role.

For manufacturers, this represents both a new challenge and a huge opportunity. Mastering advanced CNC machining ensures quiet, efficient reduction units and gives companies a competitive edge in the rapidly growing EV market. After all, the smoothness of the driving experience lies hidden in the tiniest details of these gears.

.jpg)

.jpg)

.jpg)