Precision machining is the process of removing material from a workpiece to chang the dimensions or properties of the workpiece so that is can become a more precise product that will meet very exact specifications.

What is Precision Machining?

Precision machining is the process of removing material from a workpiece until it meets precise tolerances. There are many types of precision machine tools, including milling, turning, and electrical discharge machining (EDM) tools. Precision machining tools can be controlled by computers, and these machines are called Computer Numerical Control (CNC) machining tools.

Almost all metals, and many other materials, such as plastic and wood, can be precision machined using precision machining tools. These machines are operated by professional and well-trained mechanics. In order for the cutting tool to do its job, it must move in the specified direction in order to make the correct cut. The rate at which material is removed from the workpiece is called the "cutting speed." The workpiece can also be moved during machining, and this secondary movement is called "feeding." These actions, along with the sharpness of the cutting tool, determine the efficiency and accuracy of the precision machine.

High-quality precision machining requires the ability to follow specific blueprints produced by CAD (Computer Aided Design) or CAM (Computer Aided Manufacturing) programs such as AutoCAD and TurboCAD. The software can help create complex 3D diagrams or outlines needed to manufacture tools, machines or objects. These blueprints must be strictly followed to ensure product integrity. Although most precision machining companies use some form of CAD/CAM program, they still often use hand-drawn sketches in the initial stages of design.

Precision machining is used on a variety of materials, including steel, bronze, graphite, glass and plastic, to name a few. Depending on the sizes of the project and the materials used, a variety of precision machining tools will be used. Any combination of lathes, milling machines, drilling machines, saws and grinders, and high-speed robots can be used. The aerospace industry may use high-speed machining, while woodworking tool manufacturing may use photochemical etching and milling processes. Production runs or a specific number of any particular item can be in the thousands, or just a few. CNC equipment allows precise dimensions to be followed throughout the product run.

What is CNC?

CNCs automate machine tools by executing pre-programmed sequences of machine control commands through a computer. This is in contrast to machines that are manually controlled by handwheels or levers, or mechanically controlled by cams alone.

In modern CNC systems, the design of mechanical parts and their manufacturing procedures is highly automated. The mechanical dimensions of the part are defined using CAD software and then translated into manufacturing instructions by CAM software. The generated instructions are converted by ("post-processor" software) into the specific commands needed for a specific machine to produce that component and then loaded into the CNC machine.

Since any given component may require the use of many different tools - drills, saws, etc. - modern machines often combine multiple tools into a single "unit.” In other installations, many different machines are used with external controllers and robots to move components from machine to machine. In either case, the series of steps required to produce any part is highly automated and produces a part that closely matches the original CAD.

As controller hardware has evolved, so have the factories as well. As a safety measure, one change made is to enclose the entire mechanism in a large enclosure, often with additional safety locks to keep operators away from the workpiece during operation. Most new CNC systems manufactured today are 100% electronically controlled.

CNC-like systems are now used for almost any process that requires a series of movements and operations. These include laser cutting, welding, friction stir welding, ultrasonic welding, flame and plasma cutting, bending, rotating, punching, pinning, gluing, fabric cutting, sewing, tape and fiber placement, routing, pick and place, and sawing.

What is CNC Machining?

CNC machining is a manufacturing process in which pre-programmed computer software instructs the movement of factory tools and machines. This process can be used to control a range of complex machinery, from grinders and lathes to milling machines and routers. With CNC machining, 3D cutting tasks can be accomplished in one set of cues.

When a CNC system is activated, the required cuts are programmed into the software and assigned to the corresponding tools and machines that perform the prescribed dimensional tasks, just like a robot.

In CNC programming, code generators in digital systems often assume that the mechanism is flawless. But the possibility of error does exist, and errors can be multiplied whenever the machine is instructed to cut in multiple directions at the same time.

Programs for CNC machine tools are entered into a computer via a keypad. CNC programming is stored in the computer's memory. The code itself is written and edited by programmers. The CNC system is by no means static, as new cues can be added to the original program through modified code.

What is Milling Machining?

Milling is a machining process that uses a rotary cutter to remove material from a workpiece by advancing (or feeding) the cutter into the workpiece in a specific direction. The tool can also be held at an angle relative to the axis of the tool. Milling covers a variety of different operations and machines, and can be used for machining small parts as well as for large, heavy-duty combination milling jobs. Milling is one of the most common processes used for machining custom parts to precise tolerances.

Milling can be done with a wide variety of machine tools. After the advent of CNC, milling machines developed into machining centers: milling machines enhanced by automatic tool changers, tool magazines or conveyor belts, CNC functions, cooling systems and housings. Milling centers are generally classified as vertical machining centers (VMC) or horizontal machining centers (HMC).

The integration of milling and turning processes, and vice versa, was initially done combining machine turning with milling cutters. This has led to a new class of machine tools; multitasking machines (MTMs), which are specialized for milling and turning within the same working envelope.

What is Turning Machine?

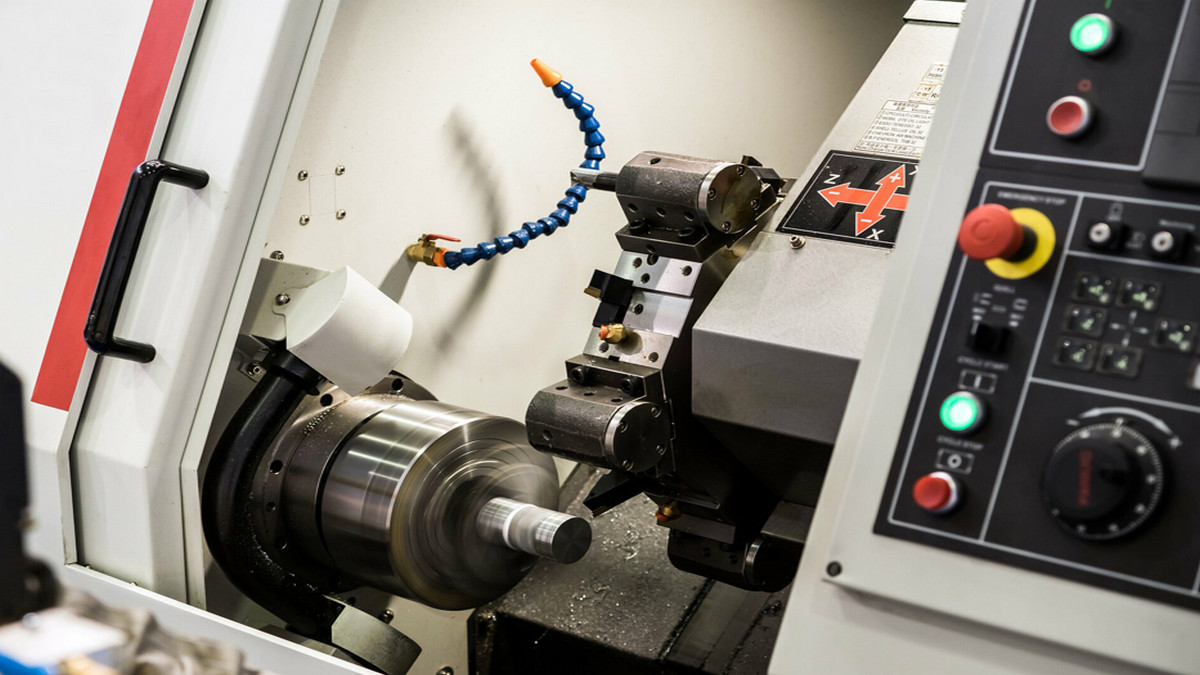

Turning involves the rotation of a workpiece (usually metal, but may also be wood, plastic or stone) near a cutting tool. Turning is usually performed on a lathe.

There are different types of turning operations including: linear turning, threading, tapered turning and external grooving. In linear turning, a single cutting tool moves in parallel across the workpiece as the workpiece rotates. In tapered turning, a tapered turning attachment is used. For external grooving turning operations, grooves are cut into the workpiece to a specific depth. Because they are in the split turning method, the grooves are not completely removed.

A lathe is used to shape material by rotating a workpiece into a cutting tool. There are three types of lathes: engine lathes which have an automated slide and power feed, turret lathes which have a turret for holding various different cutting tools, and special purpose lathes designed to perform special machining operations. Lathes can range in size from small and portable to large floor-standing machines.

What is Electric Discharge Machining?

Electric Discharge Machining (EDM) is a manufacturing process that utilizes electrical discharge to obtain a desired shape. Material is removed from the workpiece by a series of rapid and repeated electrical discharges between two electrodes, separated by a dielectric fluid and subjected to an electrical voltage. One of the electrodes is called the tool electrode, or simply "tool" or "electrode", while the other is called the workpiece electrode or "workpiece".

Wire EDM and Die Sink EDM

There are two kinds of EDM, Wire EDM and Die Sink EDM. In Wire EDM (wire erosion) a graphite wire electrode is fed into the cutting area and the graphite electrode is eroded as it machines the workpiece. The work area is submerged in deionized water which functions as an insulator and constantly flushes the conductive material.

Die Sink EDM, uses an electrode and a workpiece immersed in oil or other dielectric fluid. The electrode and workpiece are connected to a suitable power source, creating an electrical potential between the two parts. As the electrode approaches the workpiece, dielectric breakdown occurs and small spark jumps occur in the fluid that forms the plasma channel. Vaporized material is then flashed out away from the cutting area.

All of the above are processes that remove excess, raw material from a work-piece, while maintaining close tolerances, to create a finished product. Simply put, it means shaping large pieces of material into more precise items, so that they can meet very exact specifications.

.png)