Insights

With the implementation of the import substitution policy in Russia, the output of machine tools has increased, and the replacement of equipment has become one of the priority projects of Russia's "development strategy for the machine tool industry before 2030", which will inject huge business opportunities for the Russian machine tool industry.

2020-06-01 09:45:04

After "Cloud Computing", a new term "Fog Computing" has been added in recent years. It mainly comes from the phrase "fog is a cloud closer to the ground".

2020-05-29 16:27:48

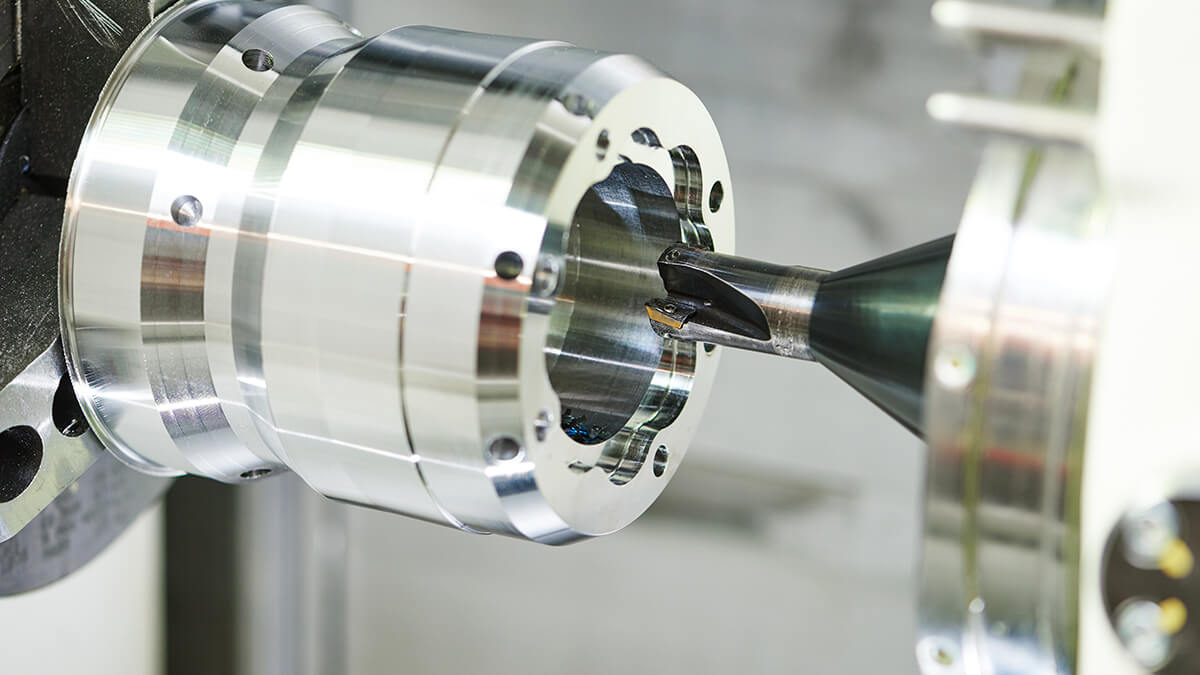

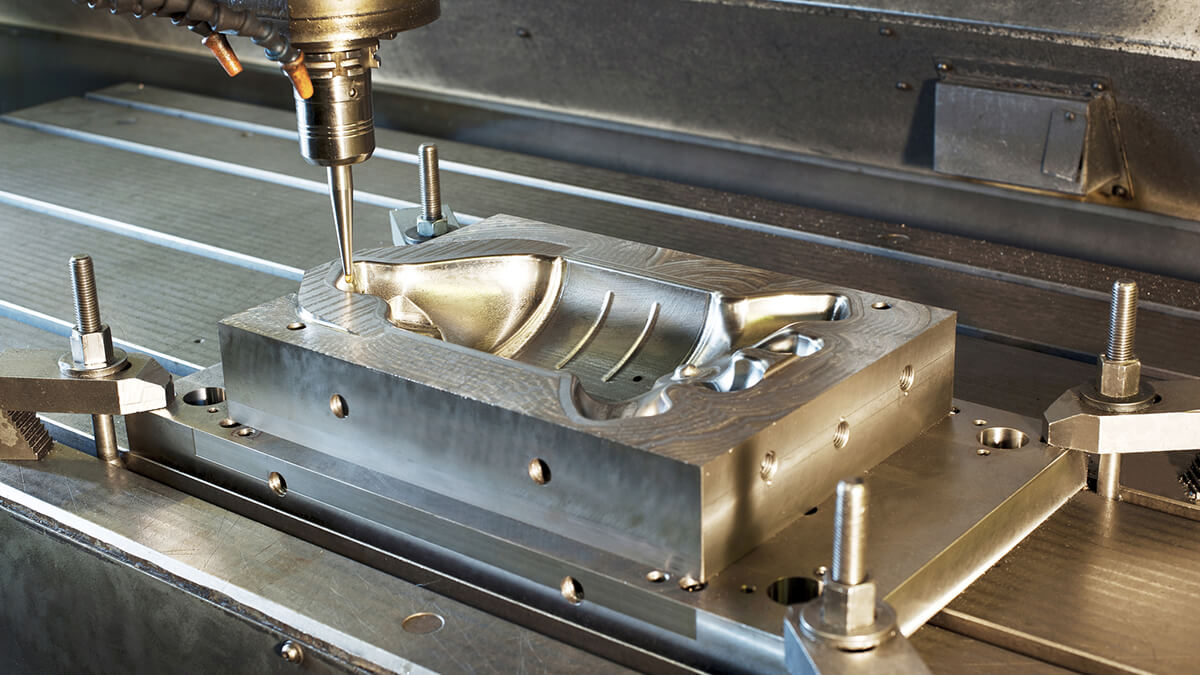

When the program enters the machine, any time saved by skipping the programming preparation is easily lost. Taking the time to prepare properly will help ensure the accuracy of the CNC program and improve efficiency.

2020-05-29 15:44:46

Edge computing technology is an extension of cloud computing. It can improve the analysis technology of cloud data. It is a concept of nearby computing. Its technology is gradually applied to various industries so that each industry can break through the existing restrictions and increase its productivity and efficiency.

2020-05-29 10:38:58

What is the development and application prospect of edge computing? When cloud computing is not enough to process and analyze data generated or to be generated by IoT devices, connected cars and other digital platforms in real time, edge computing will come in handy. Edge computing technology has the potential to be applied in many industries and plays a huge role.

2020-05-29 09:47:36

Edge computing is a distributed computing architecture that moves applications, data, and services from the central node of the network to the logical edge nodes of the network for processing. Edge computing decomposes large-scale services that were originally processed by the central node into smaller and more manageable parts, and is distributed to the edge nodes for processing.

2020-05-28 11:58:40

Under the leading policy of "Industry 4.0" in Germany, the manufacturing industry followed the concept of "smart manufacturing", and introduced the digital application of machinery into the factory. Based on the information technology services that belong to the energy economy category, it was imported from cloud software. Optimize the process. This kind of service platform is built on a modular structure that can be flexibly combined and uses AI to assist in providing strategic recommendations to achieve the energy-saving benefits of IoT machines.

2020-05-28 10:31:11

Industry 4.0 is well underway and already having a big impact on manufacturing throughout the world. Technologies such as IIoT, big data and analytics, digital twin/thread, and the smart connected factory and supply chain are all elements of Industry 4.0 that are becoming ubiquitous in almost every manufacturing company.

2020-05-28 10:17:41

Stamping is a process in which thin walled metal parts are shaped by punches and dies.

2020-05-28 09:40:25

Japanese machine tool factory develops next-generation business opportunities, demands for replacement machines and introduces 5G services.

2020-05-28 09:06:58

Hot Topic

Agree