- Showing results for

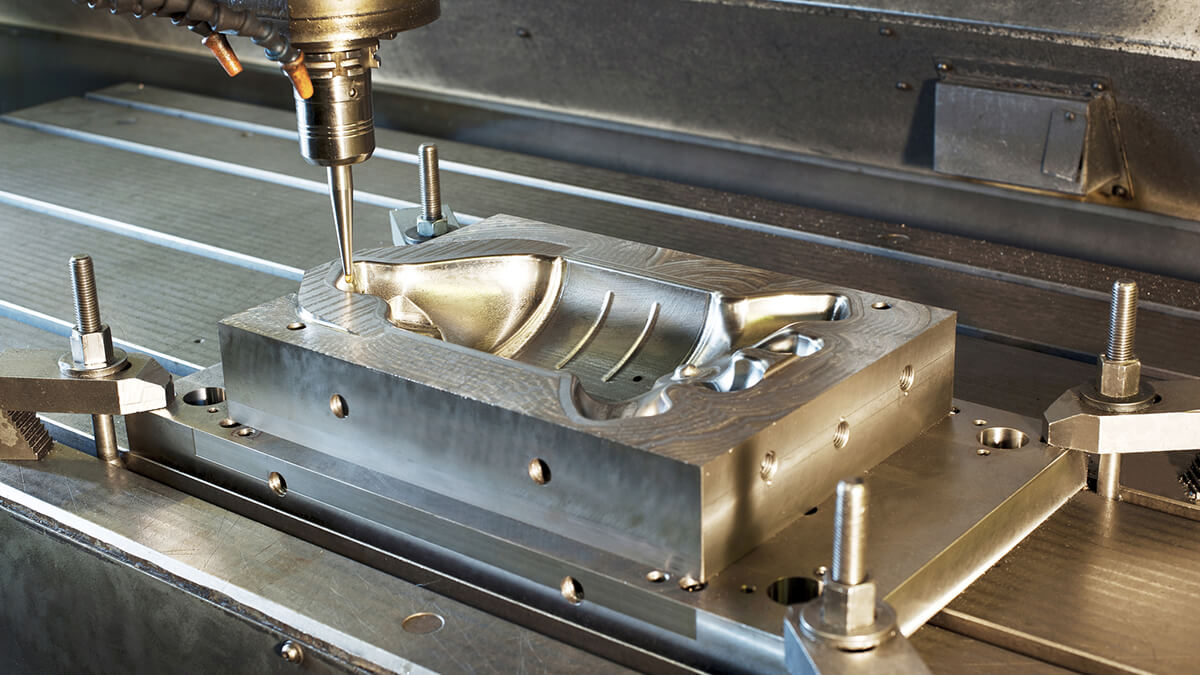

- Processing Method

Stamping is a process in which thin walled metal parts are shaped by punches and dies.

2020-05-28 09:40:25

In the field of manufacturing processing, common processing methods include broaching, boring, grinding, milling, etc.

2020-06-08 11:06:20

Aerospace components must guarantee personnel safety and facilitate the optimal performance of high-precision instruments and machines.

2020-07-23 15:21:41

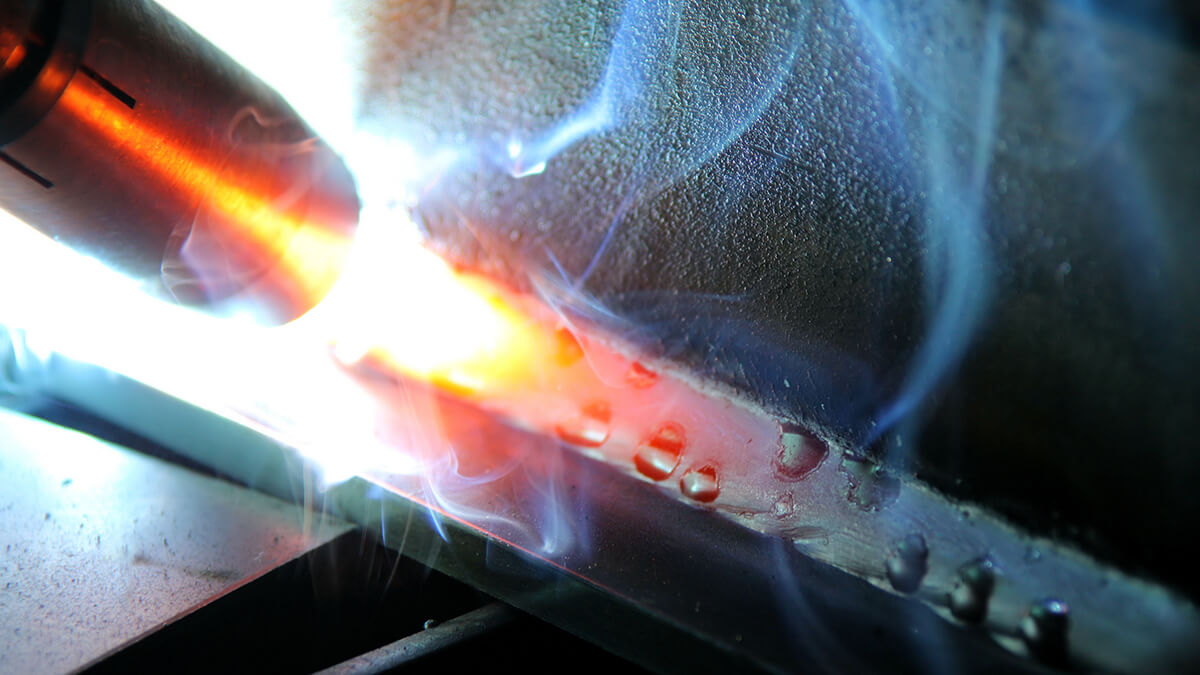

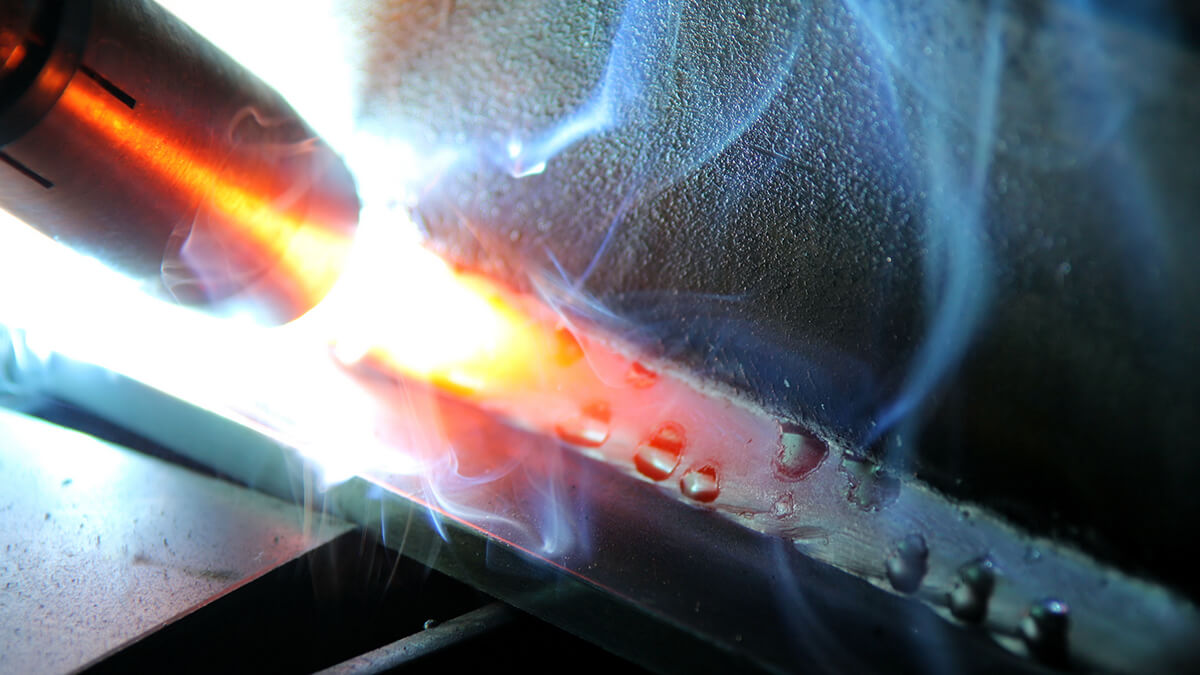

Titanium alloys are widely used in aerospace, chemical, marine, and automotive industries due to their excellent strength-to-weight ratio, corrosion resistance, and ability to maintain strength at high temperatures. However, the disadvantages of titanium alloys are poor thermal conductivity and strong reactivity with tool materials. Their high strength, and low elastic modulus make them difficult to cut materials.

2022-03-21 10:47:12

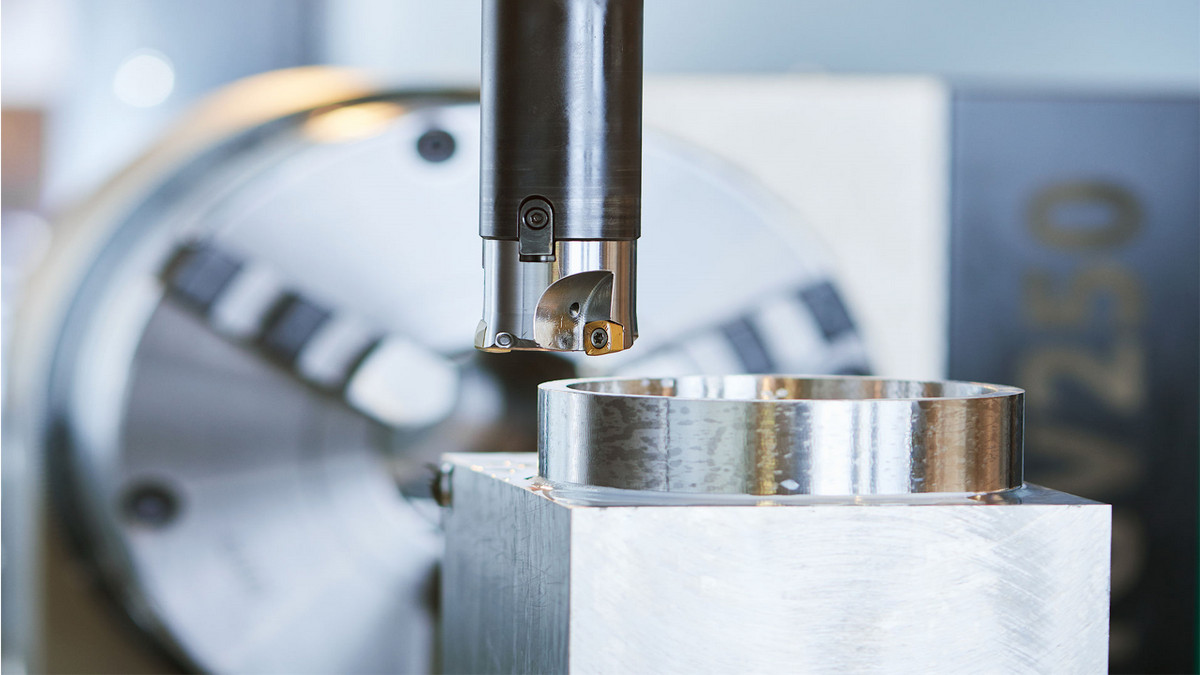

Honing is a common procedure, similar to grinding, which is a used on the inside surface of a cylinder, tube, or bore hole after precision machining and grinding. It is performed as a final procedure after grinding, to attain a precise shape and high-quality surface finish on a workpiece.

2022-05-12 10:08:47

Ultra-precision machining technology is an important way to improve the performance, quality, service life and reliability of electromechanical products, as well as saving materials and energy. For example: improving the machining accuracy of cylinders and pistons can improve the efficiency and horsepower of automobile engines and reduce fuel consumption; improving the machining accuracy of rolling elements and raceways of rolling bearings can increase the speed of bearings, reduce vibration and noise; improve flatness of processing of magnetic disks, thereby reducing the gap between it and the magnetic head, can greatly increase the storage capacity of the magnetic disk; improving the marking accuracy of the semiconductor device (reducing the line width, increasing the density) can improve the integration of the microelectronic chip, etc.

2022-07-07 11:24:39

Metalworking is the production activity of applying various processes to metallic materials to manufacture desired parts, assembly line components or overall large structures. Do you know what metal processing is? The process of metal processing is roughly divided into three categories, namely metal forming, metal cutting and metal joining. This article will give a further introduction to metal cutting.

2022-12-12 15:17:20

Milling machines have better chip evacuation because of the nature of their configuration because gravity keeps the chips from falling. This helps improve the surface finish and prolongs the life of the tool.

2022-12-13 09:23:48

In the field of manufacturing processing, common processing methods include broaching, boring, grinding, milling, etc.

2023-08-31 10:03:06

Agree