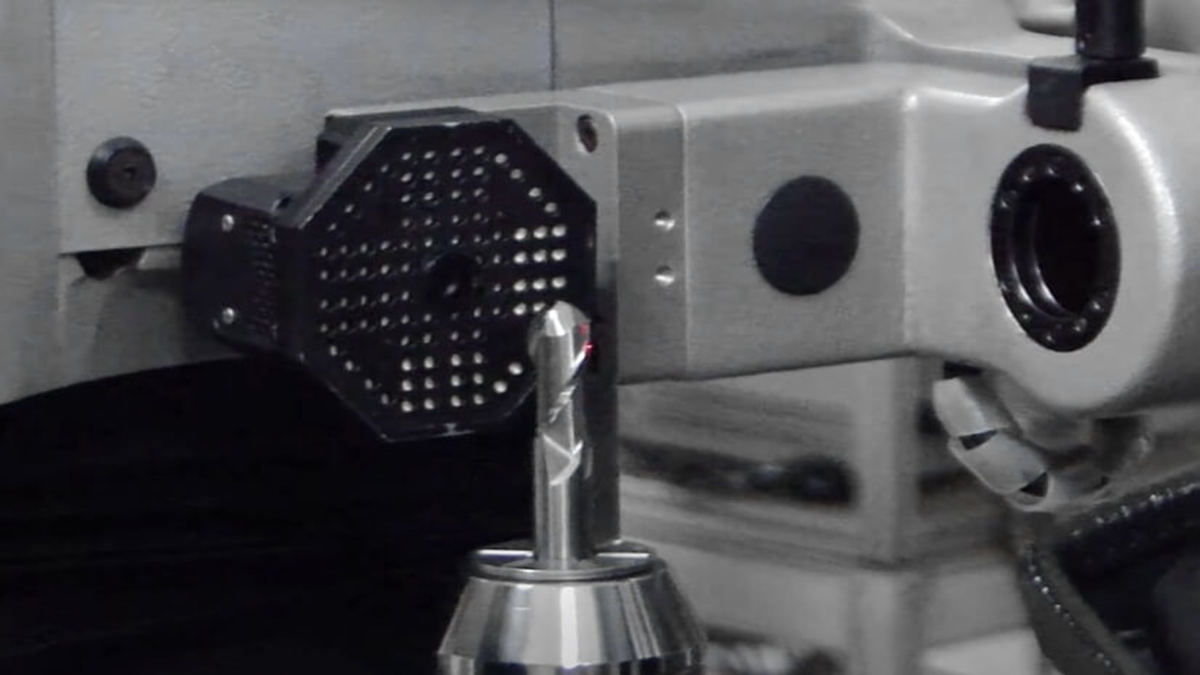

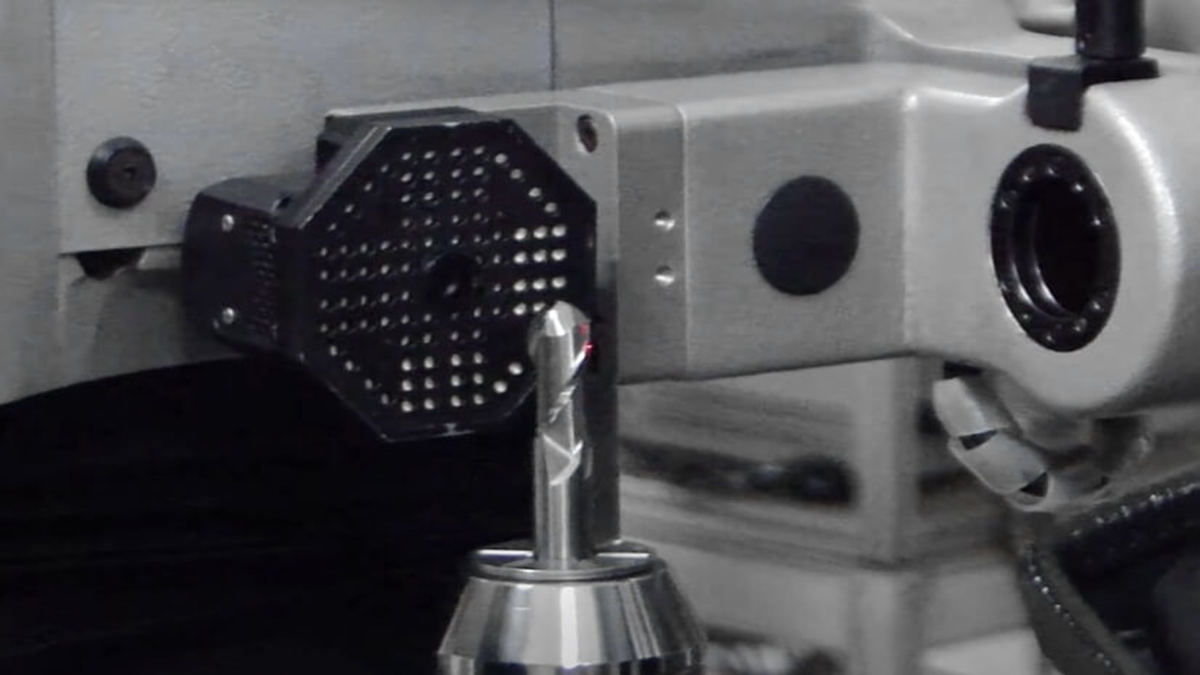

Cutting tools are a cornerstone of modern manufacturing. Their importance goes beyond the production line; they are fundamental to a product's quality, efficiency, and cost. They can be seen as the key technology that "brings materials to life," and their performance directly impacts the final product's precision, efficiency, and potential for innovation.

Photo by https://www.endmill-tool.com/storage/media/index/about-pic.jpg

JUN-YI Company

Cutting tools play a crucial role in the creation of every precision component. They aren't just simple tools; they are the foundation that determines the final product's accuracy, efficiency, and cost. JUN-YI understands this, which is why we provide a complete and interconnected series of precision cutting solutions, from initial positioning to final finishing.

Based on our engineering expertise, we offer cost-effective tooling solutions through extended tool life, technical support, advanced coatings, and an efficient inventory management system. We also provide custom cutting tools designed for specific materials and processing requirements. These custom tools offer a more precise and efficient cutting experience, which in turn boosts productivity and reduces costs.

We believe that high-quality tools not only extend service life and increase productivity but also turn innovative designs into reality.

Product Description

- End Mills

End mills are versatile cutting tools used on milling machines or CNC machining centers for a variety of cutting operations. Their main function is to remove excess material from a workpiece to create a desired shape and structural features. Typically, they consist of one or more cutting teeth that sequentially remove material from the workpiece during the machining process, enabling efficient and precise material removal. They are one of the most fundamental and essential tools in modern precision manufacturing.

Among the various milling tools, carbide end mills have become the mainstream choice in CNC machining due to their outstanding performance and wide range of applications.

- Carbide Position Drills

Carbide position drills are specialized drilling tools made from tungsten carbide, known for their exceptional hardness and durability. These drills are designed to provide high-precision drilling, making them ideal for various industrial applications. Their high hardness, wear resistance, and heat resistance make them an indispensable tool in modern manufacturing and machining environments, suitable for a wide range of industries.

- Carbide Reamers

Carbide reamers are precision cutting tools made from tungsten carbide, specifically designed for enlarging holes and finishing them in various materials, especially metals. They are essential in the machining and metalworking industries because they can achieve strict tolerance control and superior surface finishes.

- Replaceable End Mill Head & Anti-Vibration Tool Holder

Replaceable end mill heads are milling tools designed for highly efficient machining operations. The modular design allows the cutting head to be changed independently of the tool holder. This enables users to keep the same tool holder while replacing worn or damaged heads, which significantly improves cost-effectiveness and operational efficiency.

Customized Cutting Tools

To meet various specialized needs, JUN-YI provides professional customized cutting tool services. We design tools based on your specific material and processing requirements. This not only significantly boosts work efficiency and reduces wear and breakage, but also ensures product quality. For high-precision manufacturing, our custom tools are key to minimizing defects and rework, helping you achieve ultimate precision and efficiency.

Your Challenge, Our Mission

At JUN-YI, we believe that every excellent product is born from a commitment to detail. From our standard carbide end mills to our custom-made tools, every solution we offer is designed to extend tool life, increase productivity, and lower your overall costs. We are more than just a tool supplier; we are your most reliable technical partner on the path to precision machining.

Whether your goal is to achieve extreme accuracy or to tackle challenging materials and processes, we are ready to provide you with the most precise and effective tooling solutions through our professional technical support and innovative mindset.