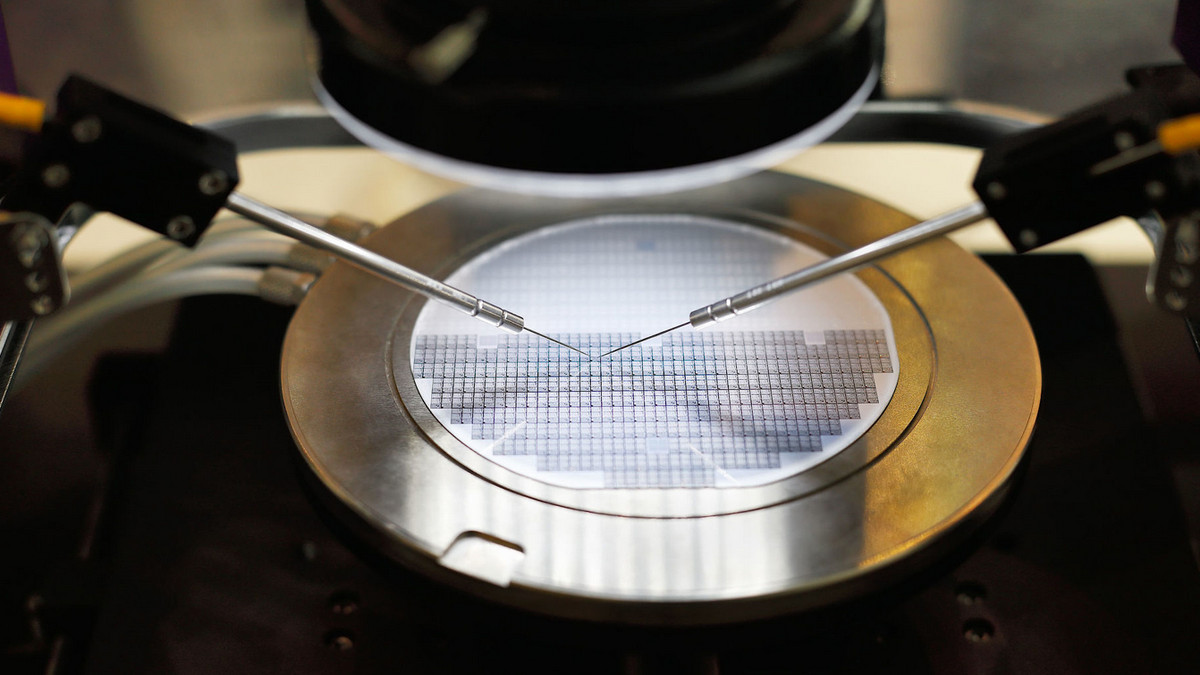

When reading or hearing about the semiconductor industry, we often hear the term wafer mentioned. But what exactly is a so-called wafer? What does an “8 inch” or “12 inch” wafer refer to? How difficult is it to produce large-sized wafers? The following is a step-by-step introduction to the most important foundation of semiconductors, the wafer.

What is a Wafer?

A wafer refers to the silicon wafer used in the fabrication of silicon semiconductor integrated circuits. Because of its circular shape, it is called a wafer. A wafer is the carrier used in the production of integrated circuits. Generally, a wafer refers to a single-crystal silicon wafer. Wafers are the most commonly used semiconductor base material, and are divided into 4 inches, 5 inches, 6 inches, and 8 inches according to their diameters. The larger the wafer, the more ICs can be produced on the same wafer, which can reduce costs. However, the requirements for material technology and production technology are higher for larger wafers. It is generally believed that the larger the diameter of the silicon wafer, the better the technology of the fab. In the process of producing wafers, the yield rate is a very important condition.

Wafers are the basis for the manufacturing of computer chips. We can compare chip manufacturing to building a house with Lego blocks, and by stacking layer by layer, we can complete our desired shape (that is, the desired chip). However, if there is no good foundation, the built house will be deformed and unsatisfactory. In order to make a perfect house, a stable base plate is required. For wafer fabrication, this substrate is the wafer described next.

I recall that when I was a child with Lego blocks, there would be small round protrusions on the surface of the blocks. With this structure, we can stably stack the two blocks together without using glue. Wafer fabrication, in a similar way, holds the subsequently added atoms together with the substrate. Therefore, we need to find substrates with neat surfaces to meet the conditions required for subsequent fabrication.

In solid materials, there is a special crystal structure - Monocrystalline. It has the property of atoms closely arranged one after the other, forming a flat atomic surface. Therefore, using a single crystal to make a wafer can meet the above requirements. However, to produce such a material, there are two main two steps, purification and crystal pulling.

How to Make a Single Crystal Wafer?

Purification is divided into two stages. The first step is metallurgical purification. This process mainly involves adding carbon to silicon oxide to convert it by redox into silicon with a purity of more than 98%. Most of the refining of metals, such as iron or copper, is done in this way to obtain metals of sufficient purity. However, 98% is still not enough for wafer manufacturing and still needs to be improved further. Therefore, the Siemens process will be used for further purification, so that the high-purity polysilicon required for the semiconductor process will be obtained.

Next, is the step of pulling crystals. The previously obtained high-purity polysilicon is melted to form liquid silicon. After that, a single-crystal silicon seed contacts the liquid surface, and is slowly pulled up while rotating. The single-crystal silicon seeds are needed to initiate the order in which the silicon atoms will arrange on the crystal as it grows. Finally, after the silicon atoms leaving the liquid solidify on the surface of the crystal, the neatly arranged monocrystalline silicon pillars are completed.

However, what do 8 inches and 12 inches stand for? This refers to the diameter of the crystal column after it is completed. How difficult is it to make large wafers? As described earlier, the accumulation on the crystal is like the process of making cotton candy. As the center is rotated multiple layers are added till you get the desired diameter. If you have made cotton candy, you will appreciate that as the core gets larger it becomes harder to make a uniform end product. With the pulling of crystals, it is the same. The speed of rotation, and control of the temperature will affect the quality of the crystal column. Therefore, the larger the size, the higher the speed and temperature requirements for crystal pulling, so it is more difficult to make high-quality 12-inch wafers than 8-inch wafers.

To obtain the wafer, this silicon pillar now needs to be cut into thin slices. A diamond knife is used to cut the silicon pillars laterally into wafers, and the wafer’s surfaces are then polished to form the final completed wafers. Once the wafer substrate is complete, the next step of stacking the circuits onto the wafer will complete the chip fabrication.

.jpg)

.png)