Insights

Industrial robots can more quickly and handle large-scale mass production work. So far, nearly half of the industrial robots in the world are used by automobile factories. Let's understand the advantages and disadvantages and applications of industrial robots.

2020-05-21 16:52:07

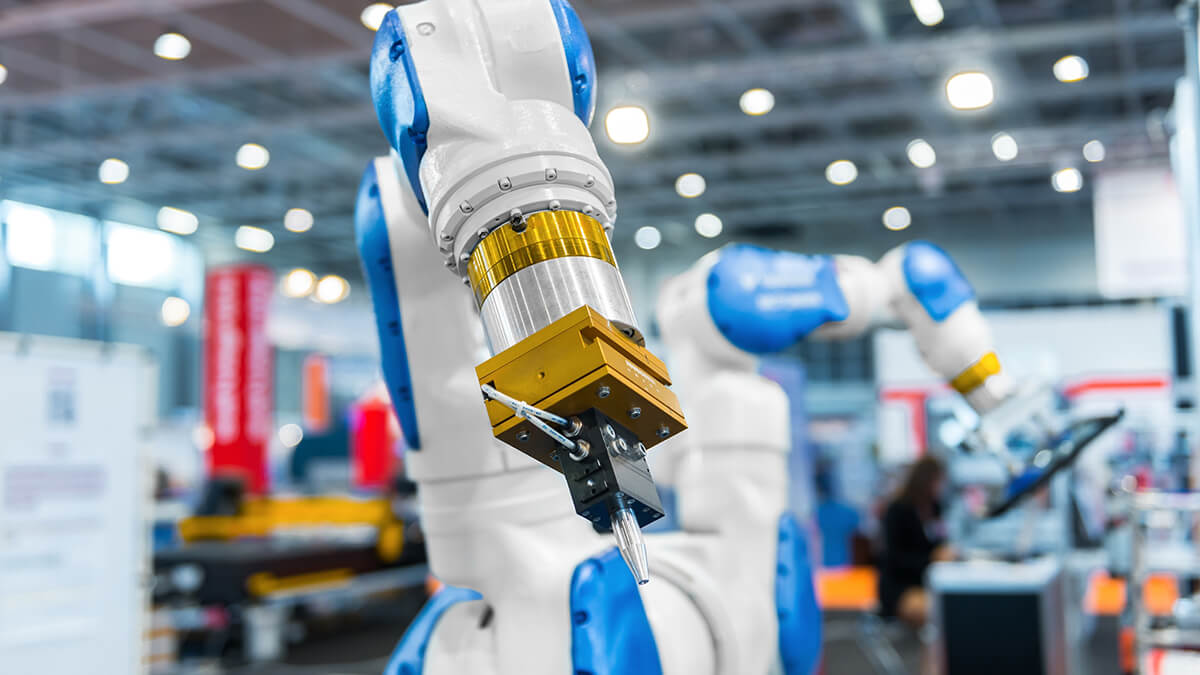

Industrial robots use a large number of sensors to achieve good operation and control in industrial automation production processes. For example, collaborative robots integrate torque sensors and cameras to ensure the best perspective and safety. What sensors are integrated with industrial robots?

2020-05-21 13:50:03

How collaborative robots join production has become a link in the manufacturing chain, improving production efficiency. The small-scale collaborative industrial robot can be operated in a narrower place to solve the problem of working space limitation.

2020-05-21 11:28:57

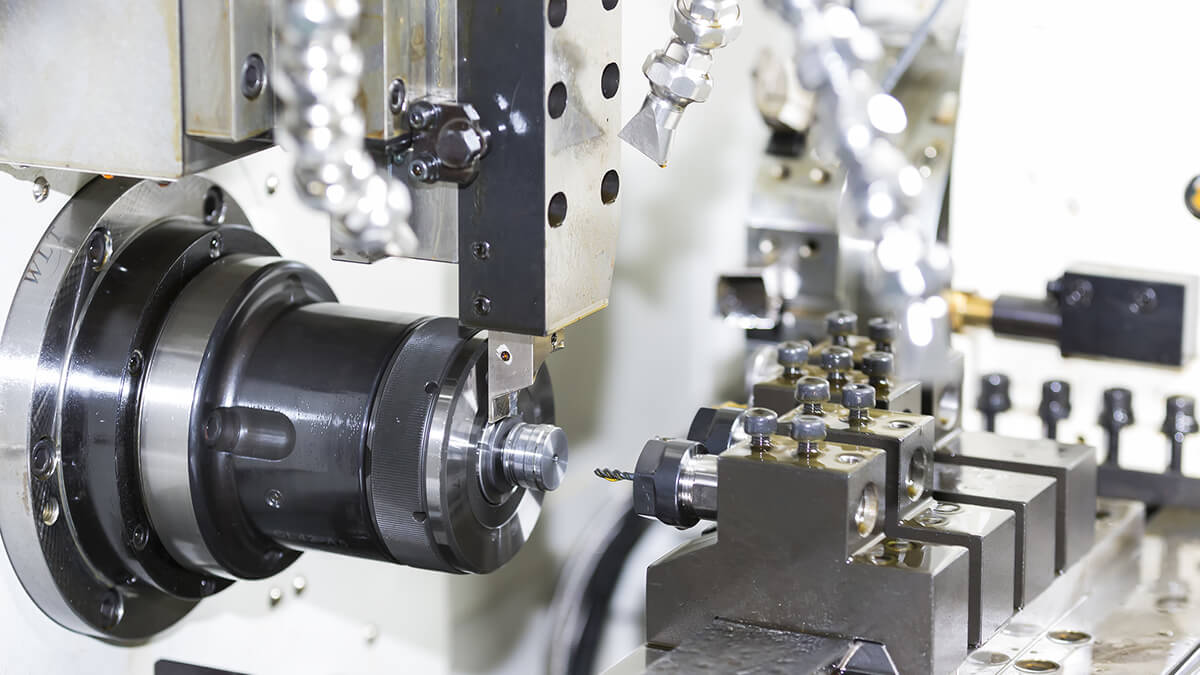

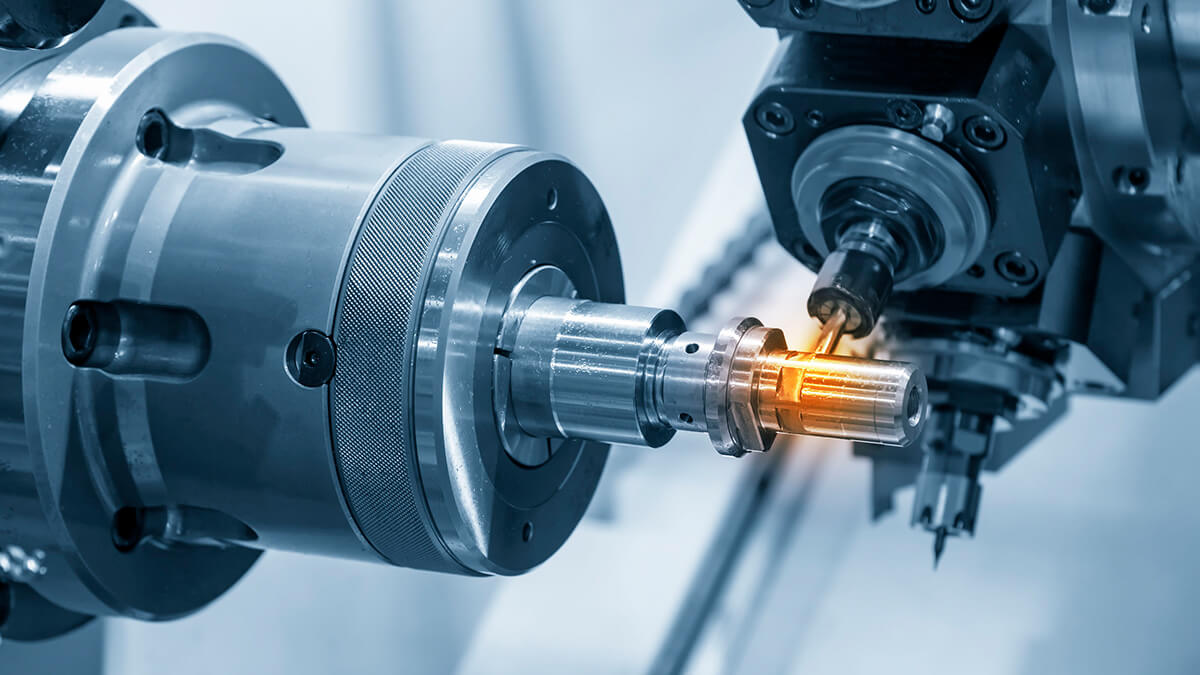

Machine tools can be said to be the mother of various industries, and countries have different marketing strategies based on their production manpower and resources.

2020-05-20 13:53:12

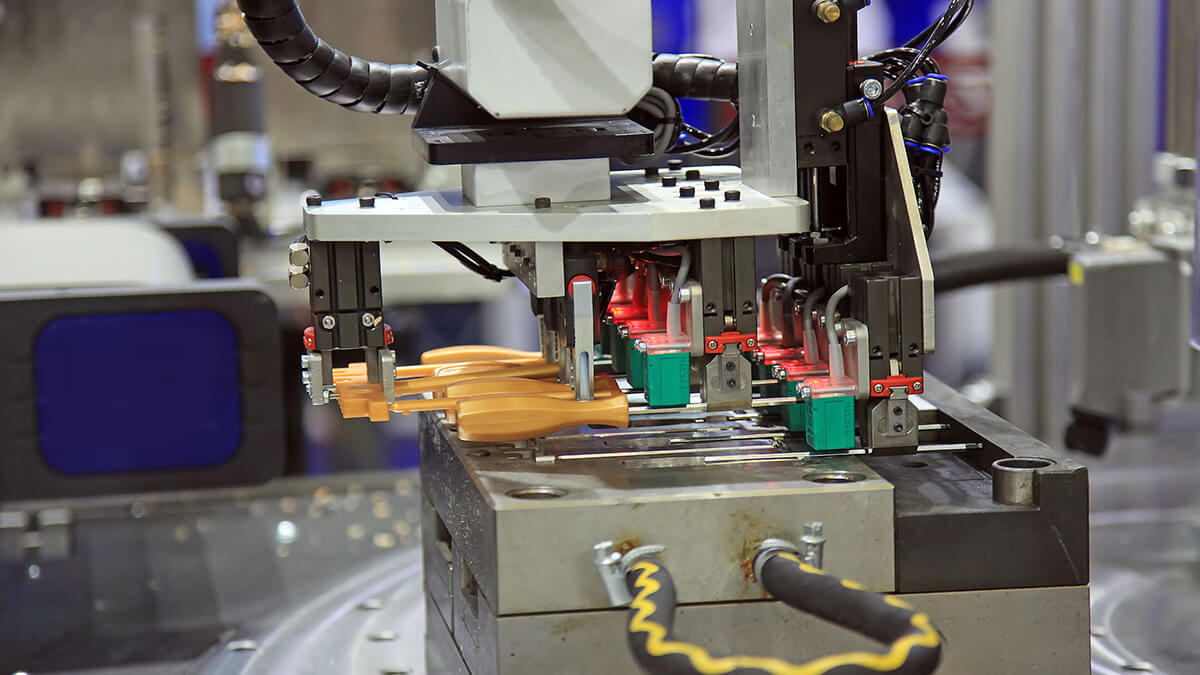

An important issue in the development of smart manufacturing is human-computer collaboration, and true human-computer collaboration does not only mean cooperation and coexistence. As the frequency of man-machine operations working together in the same workspace is getting higher and higher, many sensors are also appearing to assist in monitoring and preventive control.

2020-05-20 11:17:12

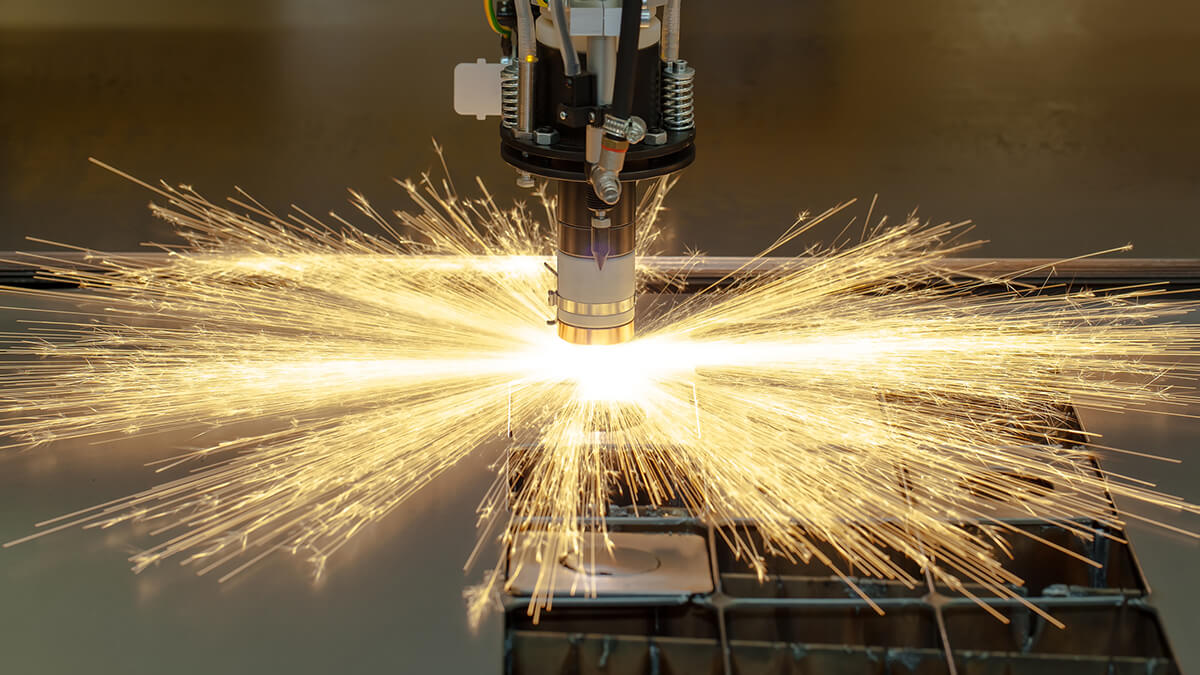

The principle of electrical discharge machining is simply a thermal processing method that converts electrical energy into heat energy of the work piece to quickly melt the work piece.

2020-05-20 09:17:50

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting. There are various grinding machine types, each with a different purpose.

2020-05-19 09:44:27

No manufacturer wants their production machinery to break down. Preventive maintenance is designed to avoid expensive interruptions to operations. However, some failures can’t be avoided.

2020-05-18 15:35:14

What is AOI? It is an automatic optical inspection (AOI) technology. Its advantages include non-contact, fast speed, high accuracy and high stability. It can solve the defects of manual visual inspection in quality management.

2020-05-18 11:47:54

A shaper is a type of machine tool that uses the linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

2020-05-18 11:00:27

Hot Topic

Agree