In the world of CNC roll grinding, precision, durability, and efficiency are paramount. Proma Grinder, a professional manufacturer specializing in CNC L-type, M-type, H-type, S-type roll grinders, cylindrical roll grinders, and standard manual grinding machines, has been revolutionizing the industry with their advanced equipment. With a commitment to quality and innovation, Proma Grinder has established itself as a trusted provider of high-performance grinding solutions.

In the world of CNC roll grinding, precision, durability, and efficiency are paramount. Proma Grinder, a professional manufacturer specializing in CNC L-type, M-type, H-type, S-type roll grinders, cylindrical roll grinders, and standard manual grinding machines, has been revolutionizing the industry with their advanced equipment. With a commitment to quality and innovation, Proma Grinder has established itself as a trusted provider of high-performance grinding solutions.

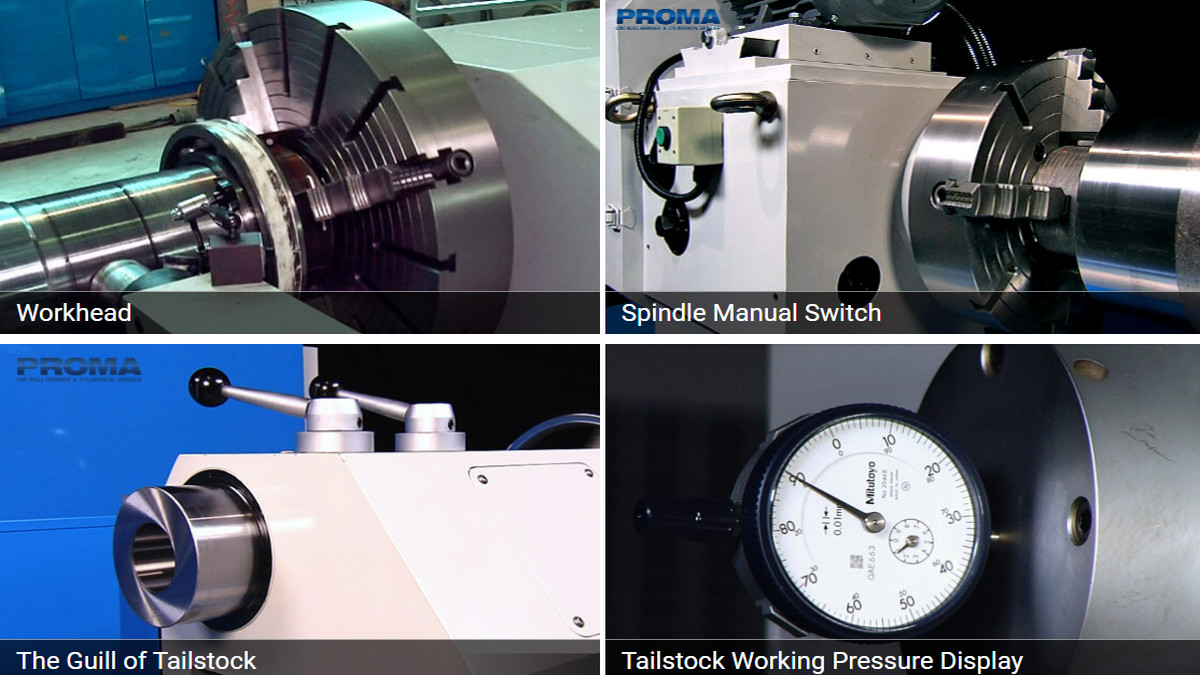

Special Features and Considerations in CNC Roll Grinders

CNC L-type, M-type, H-type, S-type roll grinders, and cylindrical roll grinders are designed to meet specific industry requirements. Here are some of the special features and considerations that make these machines essential in the roll grinding process:

Robust Construction:

Proma Grinder understands the demands of heavy-duty applications. Their CNC roll grinders are constructed with high-strength FC-30~FC-35 castings for the table, headstock, machine base, and carriage. This robust construction ensures stability, rigidity, and durability, even when dealing with large and heavy workpieces.

Lubrication System:

To achieve optimal performance and part finish, Proma Grinder incorporates a hydrodynamic hydrostatic lubrication system in their CNC roll grinders. This system constantly lubricates the guideways, reducing drag between components and enhancing the precision of the grinding process.

Wheelhead Design:

The wheelhead spindle plays a crucial role in the grinding finish and strength. Proma Grinder's CNC roll grinders are equipped with hydrodynamic bearings and are made of Ni-CR-Mo alloy, providing superior strength and maximum grinding finish. This design ensures stability and precision during the grinding operation.

Automation and CNC Control:

Proma Grinder's CNC roll grinders are equipped with a FANUC CNC controller, enabling automated roll grinding processes. With a user-friendly operation panel, operators can easily develop and execute grinding programs, making the grinding operation efficient and precise. This automation streamlines the grinding process, reduces human error, and increases productivity.

Tailstock Features:

Tailstock re-positioning is simplified through the use of an air assist device mounted on the bottom of the tailstock, ensuring ease of operation. Workpiece alignment is achieved via tailstock adjustment, and an optional revolving 4-jaw chuck tailstock is available for heavy workpieces.

Efficiency and Cost-Effectiveness in Manufacturing

Proma Grinder integrates several features and design considerations in their CNC roll grinders to enhance quality, efficiency, and cost-effectiveness:

Advanced Grinding Techniques:

By utilizing CNC technology, Proma Grinder's roll grinders offer precise and consistent grinding results. The machines can achieve various grinding profiles, including base arc curve, SINE curve, COSINE curve, CVC curve, and combined arc curve. This versatility allows for customized grinding solutions based on specific roll requirements.

Integration of Maintenance Functions:

Proma Grinder's CNC roll grinders incorporate a net function that facilitates the output and input of cutting data and machine parameters, streamlining maintenance procedures. This integration enhances productivity by minimizing downtime and ensuring optimal machine performance.

Proma Grinder has established itself as a leading manufacturer of CNC roll grinders, catering to diverse industries with their specialized L-type, M-type, H-type, S-type roll grinders, cylindrical roll grinders, and standard manual grinding machines. With features such as robust construction, precision wheelhead design, advanced automation, and user-friendly operation, Proma Grinder's equipment offers superior quality, efficiency, and cost-effectiveness in the roll grinding process. Their commitment to innovation and customer satisfaction solidifies their position as an industry leader in the CNC roll grinding sector.