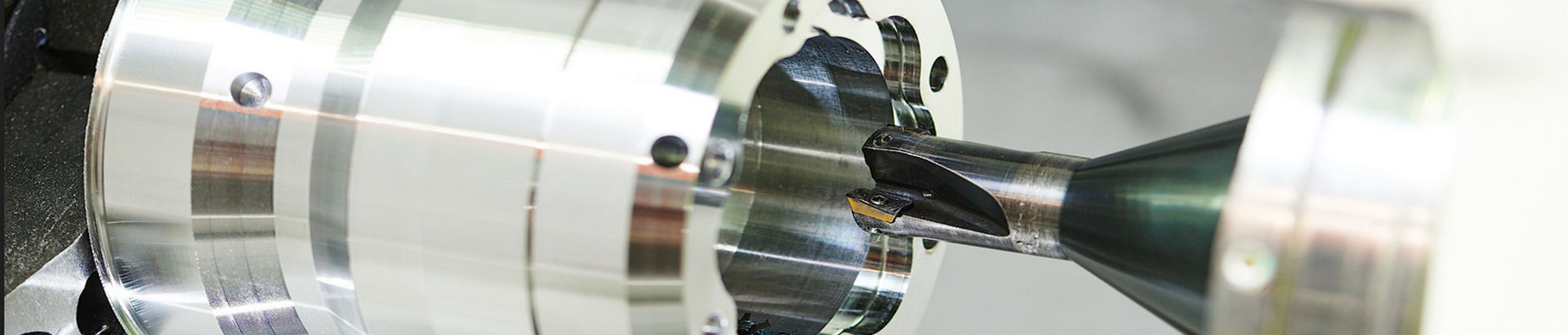

Machine tool is a machine for manufacturing various machines and processing equipment, which occupies a key position in the national industrial development. In response to the global digital transformation, machine tools are also moving towards smart machines.

What is the Definition of a Machine Tool?

A machine tool is a machine that processes blanks or workpieces of metal or other materials to obtain the required geometric shape, dimensional accuracy, and surface quality.

The parts of various mechanical products are usually processed by machine tools. A machine tool is a machine used to manufacture machines, and it is also a machine that can manufacture the machine tool itself. This is the main feature of the machine tool that distinguishes it from other machines.

What are the Categories of Machine Tools?

- Metal cutting machine: To be used for cutting metal.

- Woodworking machine: Used for cutting wood.

- Special processing tool machine: Special processing of workpieces by physical, chemical, and other methods.

- Forging machinery: The machine tool in the narrow sense only refers to the most widely used and largest number of metals cutting machine tools.

What are the Classification Methods of Metal Cutting Machine Tools?

- According to the processing method or processing object: Can be divided into lathes, drilling machines, boring machines, grinding machines, gear processing tools, thread processing tools, spline processing tools, milling machines, planers, slotting machines, broaching machines, special processing tools, sawing machines, and engraving machines, etc. Each category is divided into several groups according to its structure or processing object, and each group is divided into several types.

- According to the size of the workpiece and the weight of the machine tool: Can be divided into instrument machine tools, small and medium-sized machine tools, large machine tools, heavy-duty machine tools, and super heavy-duty machine tools.

- According to the machining accuracy: Can be divided into ordinary precision machine tools, precision machine tools, and high-precision machine tools.

- According to the degree of automation: Can be divided into manually operated machine tools, semi-automatic machine tools, and automatic machine tools.

- According to the automatic control method of the machine tool: Can be divided into copying machine tool, program control machine tool, digital control machine tool, adaptive control machine tool, machining center, and flexible manufacturing system.

- According to the scope of application of machine tools: Can be divided into general-purpose, specialized, and special-purpose machine tools.

- Among the special-purpose machine tools, there is an automatic or semi-automatic machine tool that is based on standard general-purpose components and is equipped with a small number of special components designed according to the specific shape or processing technology of the workpiece, which is called a combined tool machine.

- For the processing of one or several parts, a series of machine tools are arranged in sequence according to the process and are equipped with automatic loading and unloading devices and automatic workpiece transfer devices between the machine tools and the machine tools. Such a group of tool machines is cutting. Processing automatic production line.

- The flexible manufacturing system is composed of a group of digitally controlled machine tools and other automated process equipment. It is controlled by an electronic computer and can automatically process workpieces with different processes, and can adapt to multi-variety production.

Machine tool is the basic production equipment of the machinery industry, its variety, quality, and processing efficiency directly affect the production technology level and economic benefit of other mechanical products. Therefore, the modernization level and scale of the machine tool industry, as well as the quantity and quality of the machine tools owned are one of the indicators for evaluating the degree of industrial development of a country.

How does the Machine Tool Works?

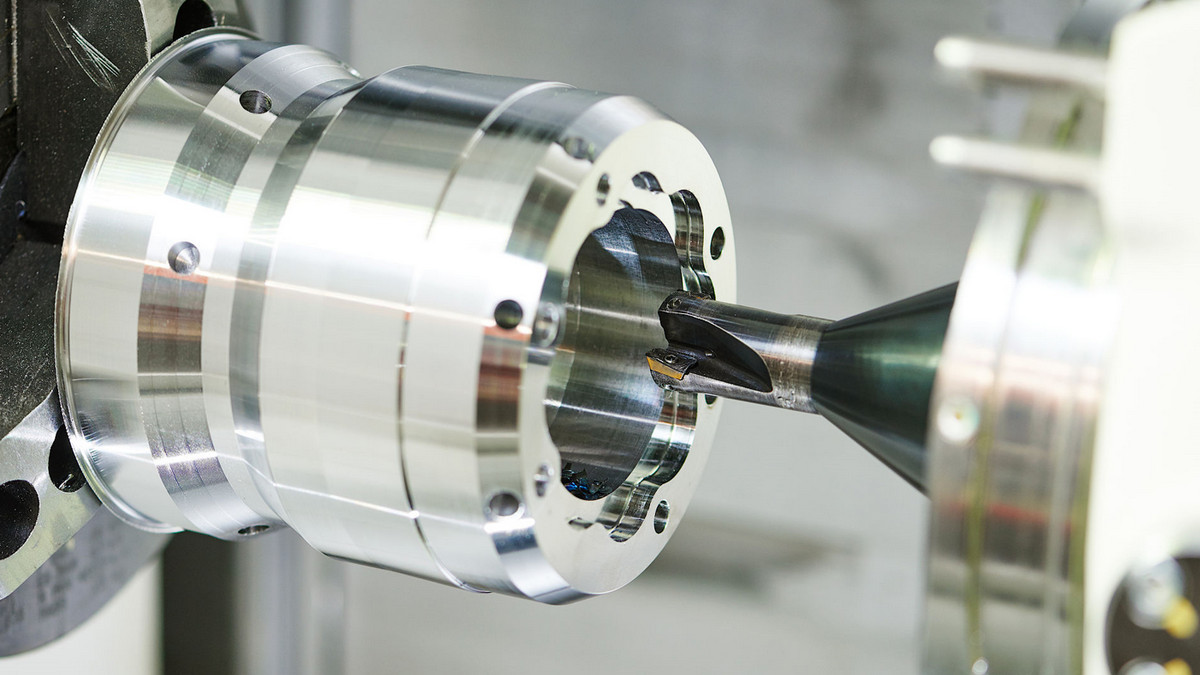

The cutting process of the machine tool is realized by the relative movement between the tool and the workpiece, and its movement can be divided into two types: surface forming movement and auxiliary movement.

The surface forming movement is the movement to obtain the required surface shape and size of the workpiece, and it includes the movement, the feeding movement, and the plunging movement. The motion is the motion that plays a major role in stripping excess material from the workpiece blank, it can be the rotary motion of the workpiece (such as turning), the linear motion (such as planning), or the rotary motion of the tool (such as milling and drilling).) or linear motion (such as plunging and broaching).

The feed movement is the movement of the tool and the workpiece to be machined toward each other so that the cutting can continue, such as the movement of the tool holder slide along the machine tool guide rail when turning the outer circle, its function is to cut a certain thickness of material from the workpiece surface in each cutting stroke, such as the lateral cutting movement of the small tool holder when turning the outer circle. Auxiliary movements mainly include the rapid approach and withdrawal of the tool or the workpiece, the adjustment of the position of the machine tool parts, the workpiece indexing, the indexing of the tool rest, the feeding of the clamping material, the movement of starting, shifting, reversing, stopping and automatic tool changing.

Various types of machine tools are usually composed of the following basic parts: supporting parts, which are used to install and support other components and workpieces, and bear their weight and cutting forces, such as bed and column. A speed change mechanism is used to change the speed of the main movement. The feed mechanism is used to change the feed amount. The headstock is used to install the machine tool spindle. There are tool holders, tool magazines, control and manipulation systems, lubrication systems, and cooling systems.

Machine tool attachments include machine tool attachments such as machine tool loading and unloading devices, manipulators, and industrial robots, as well as machine tool attachments such as chucks, suction cup collets, vices, rotary tables, and indexing heads. The indicators of the technical performance of the machine tool can ultimately be attributed to the machining accuracy and production efficiency. The machining accuracy includes the dimensional accuracy, shape accuracy, positional accuracy, surface quality, and accuracy retention of the machine tool of the workpiece to be machined. Productivity relates to machining time and auxiliary time, as well as the degree of automation and operational reliability of the machine tool. These indicators depend on the one hand on the static properties of the machine tool, such as static geometric accuracy and stiffness. On the other hand, it has a greater relationship with the dynamic characteristics of the machine tool, such as motion accuracy, dynamic stiffness, thermal deformation, and noise.

Other Factors that Affect the Stable Machining of the Machine Tool:

A machine tool is a machine for cutting and grinding metal processing and making it into the shape and size required by the processor. It is used in machinery, automobiles, electronics, molds, aerospace, etc., and is a very important basic industry. The machinery industry is also the cornerstone of the development of the manufacturing industry. Any manufacturing activity requires sophisticated machinery and equipment to complete.

Counterweight form:

The up-and-down movement of the machine spindle during machining will generate gravity, acceleration, and temperature rise, which will affect the positioning and repeatability of the machine. It is necessary to eliminate the inertia generated by the counterweight system to improve machining accuracy and speed.

- Counterweight block counterweight: The weight of the counterweight body is used to offset the weight of the spindle unit, thereby increasing the rapid traverse speed of the machine tool, reducing the load on the lead screw, and reducing the motor load.

- Pneumatic cylinder counterweight: The external air pressure is passed through the check valve into the inlet of the air cylinder, from the outlet of the air cylinder to the air inlet of the cylinder, and the weight of the main shaft unit is offset by the upward thrust of the piston.

- Hydraulic cylinder counterweight: The hydraulic pressure is transmitted to the counterweight hydraulic steel and then transmitted to the main shaft unit, giving upward force to the main shaft unit to achieve the purpose of reducing the weight of the main shaft unit.

- Nitrogen counterweight: No external power equipment, energy-saving, good response characteristics, suitable for high-speed cutting, small footprint, stable balance force, and at the same time, the weight of the spindle box is directly transferred to the column base to reduce column deformation.

- Servo motor counterweight: The screw is enlarged, and the main shaft does not pass the counterweight. The servo motor directly drives the screw to drive the main shaft to move up and down.

Machine tool thermal stability core technology:

The current cooling control method of machine tools adopts constant temperature and constant flow control. Even if the temperature can be controlled within a range of ±0.2°C or even smaller, it is impossible to change the cooling target according to different loads, which makes the warm-up time longer and the heat generated. The error also varies with load transitions. Taking the maintenance of the thermal overhang of the main shaft as the control target, the heat transfer fluid is rapidly heated during the initial cold start of the machine or loading and unloading, shortening the machine warm-up time, and maintaining the main shaft overhang length. During continuous processing, the heat transfer fluid is also rapidly cooled. Therefore, no matter how the spindle speed and load change, the system will compensate with the preset target overhang instead of cooling control with a fixed temperature. In addition to shortening the warm-up time, it can also reduce the geometric changes of the machine due to load changes, and improve the machining accuracy of the machine.

The cooling system takes the preset optimal processing temperature point (obtained from the experiment) as the temperature tracking target. During the initial cold start of the machine or the loading and unloading period (below the processing temperature point), according to the set temperature rise and thermal displacement model The curve heats the cooling medium, shortens the machine warm-up time, and maintains the processing temperature. During continuous processing (higher than the processing temperature point), the temperature will also be cooled according to the temperature rise and thermal displacement mold model curve. Controlling the flow or temperature of the cooling machine according to the actual load of the machine tool can effectively increase the duty rate and maintain the accuracy of the machine quickly and stably.

The Future Development Trend of Machine Tools:

Further apply new technologies such as electronic computer technology, new servo drive components, gratings, and optical fibers to simplify the mechanical structure, improve and expand the functions of automated work, and make machine tools suitable for incorporating into flexible manufacturing systems. Increase the speed of power main motion and feed motion, and correspondingly improve the dynamic and static rigidity of the structure to meet the needs of new tools and improve cutting efficiency. Improve machining accuracy and develop ultra-precision machining tool machines to meet the needs of emerging industries such as electronic machinery and aerospace. Develop special machining tool machines to meet the processing of difficult-to-machine metal materials and other new industrial materials.

.png)