Planetary reducer has been in existence for more than 30 years. During this long period of time, planetary reducer has gradually entered the field of automation from only appearing in high-end equipment in Europe and America, and has been widely used in machine tools, semiconductors, and packaging industries in recent years. The equipment in the medical food industry, aerospace and other fields will be used with planetary reducers. High, medium and low power servo motors with planetary reducers have become standard. What are the applications and advantages of planetary reducers? This article will let you know more about planetary reducers.

What is A Planetary Reducer?

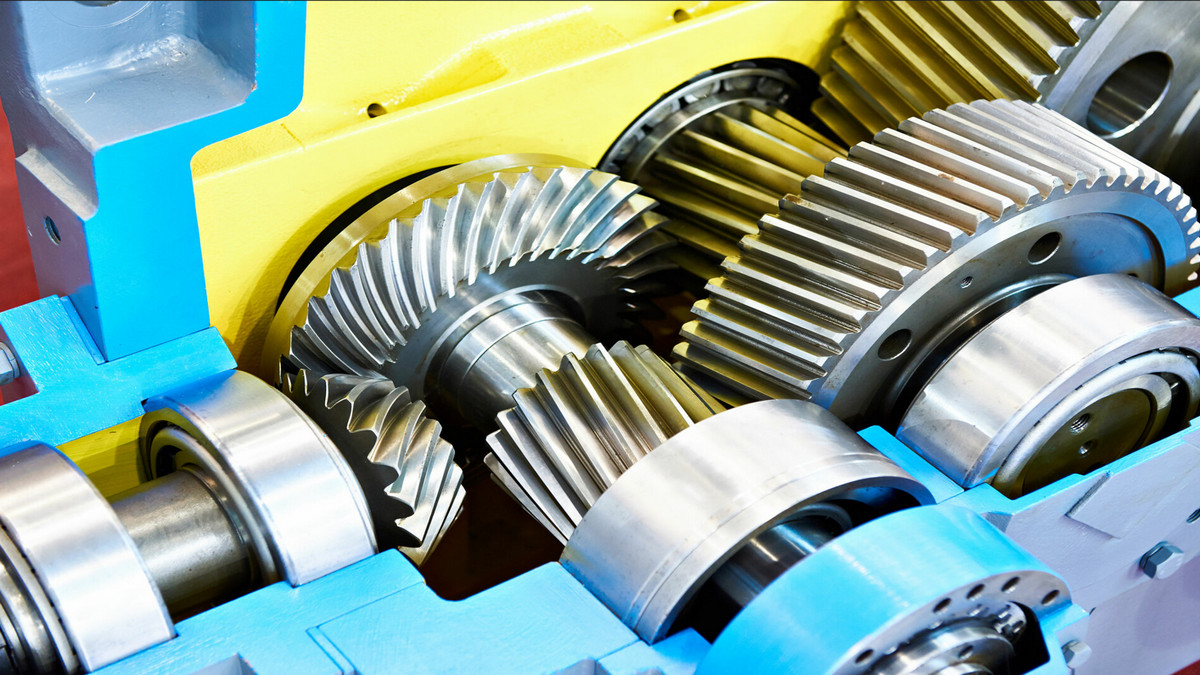

Gear reducers or gearboxes, although derived from ancient metalworking techniques, are the basis for many current innovations. The planetary reducer is a gear reducer, and the internal structure of the planetary reducer is mainly composed of four parts. They are Sun Gear, Planetary Gear, Ring Gear and Carrier. In this gear train, the outer ring gear is fixed, and the sun gear driven by the motor is located in the center of the gear train, that is, the input shaft. The sun gear is driven by the motor and simultaneously moves the planetary gears fixed in the planetary arm. In addition to its own rotation, the planetary gear also revolves around the axis of the sun gear. The planetary arm itself is the output shaft (or output shaft) of the reducer. While the planetary gear is running, it also transmits the power of the motor through the travel arm. The operation of this gear train is similar to the orbits of the planets in the solar system, which is how the planetary gear train gets its name. The reducer made with this structure is called a planetary reducer.

There are many types of reducers, with different structural designs and transmission methods, and planetary reducers are just one of them. Even so, planetary reducers can be used in countless different fields, and their uses are beyond our imagination. Planetary reducer is a multi-purpose, durable, high-precision gear reducer, which can provide high-efficiency power transmission when combined with servo motors or stepper motors. Because of its many advantages, the planetary reducer has a wide range of applications, no matter how complex or severe the conditions, it can get the job done.

What are the Advantages of Planetary Reducer?

The advantages of planetary reducer:

1. High torque density, under the same volume, it can withstand higher torque than other reducers.

2. Cost saving, with planetary reducer, the designer can use a motor with lower power, because the power becomes smaller, the cost of the overall configuration has to be greatly reduced.

3. High precision, down to one arc minute.

4. Low noise, down to 55 decibels.

5. High efficiency, up to 97%.

What are the Types and Applications of Planetary Reducers?

After years of development, the planetary reducer currently has the following styles:

Output Shaft

The planetary reducer itself has an output shaft, and the output shaft is coaxial or parallel to the input shaft. There are several forms of output shaft to choose from, for example, the common output shaft with key, which can make the reducer and the equipment end connected and assembled quickly and safely. In addition, there are optical shafts or bolt-slot shafts, etc. and other additional driving parts such as pulleys, gears, sprockets, etc. can be configured. The output shaft type planetary reducer has a wide range of applications and is suitable for almost all kinds of automation or machinery and equipment occasions. Such as machine tool, lathe, milling machine, water jet cutting machine, laser cutting machine, bottle blowing machine, rubber and plastic machinery, packaging machinery, CNC metal processing machine automatic loading and unloading automatic door-type robotic arm and so on.

Flange Type

The output side of the reducer is an output flange designed according to ISO 9409 specifications, which can be matched with various pinions, pulleys or couplings that meet this specification to easily and quickly connect to the application machinery and equipment. The flange type planetary reducer can provide higher torsional rigidity due to the structural design and the large diameter of the output flange surface, and is especially suitable for applications where the motion direction is constantly changing. Commonly used in parallel delta industrial robots with rack and pinion drives.

Right Angle

The right-angle planetary reducer is equipped with a 90-degree right-angle gearbox, which outputs the torque and speed of the servo motor at a 90-degree turn, which can save installation space and make the overall design of the equipment more compact. The output end of the right-angle planetary reducer usually also has two types of output shaft type and flange type to choose from, which can be installed and used in any direction, which greatly increases the flexibility of design and installation. It is often used in automatic mechanical devices with servo motors, photoelectric panel handling, automatic storage systems, robotic arms, pipe benders, unmanned guided vehicles (AGV), etc.

Customized Models

World Association has been focusing on the design and manufacture of motors and reducers for decades. Well-trained, professional and experienced R&D engineers and flexible coordinated manufacturing capabilities are able to develop exclusive drive solutions together with customers. Whether it is a special application environment, high output power or strength, or special requirements in surface treatment or materials, we can design, develop and manufacture according to your exact specifications, while meeting the performance, quality and cost standards you expect.

.png)