- Showing results for

- Global

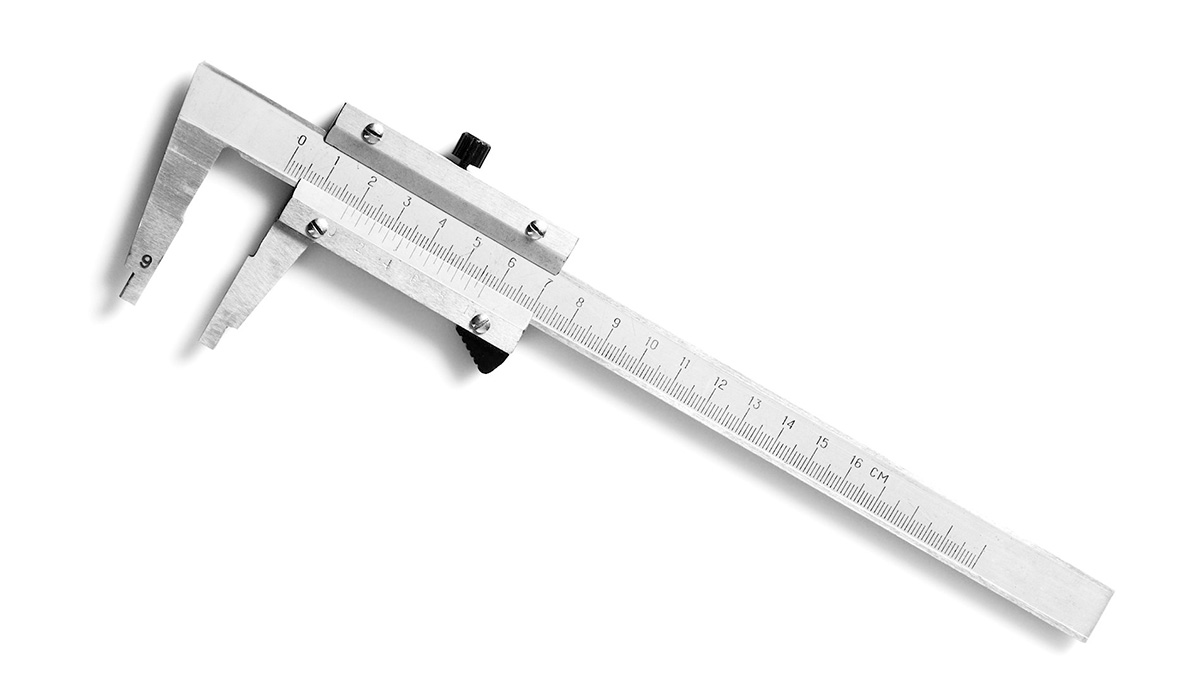

One of the tools a mechanic must use is a caliper. Although not as accurate as a micrometer, the caliper is a convenient and practical tool that can help mechanics quickly measure parts and use the measurement results to evaluate subsequent processing.

2023-08-17 13:57:49

When it comes to fasteners, everyone seems to know a little bit about it. After all, hardware such as screws and nuts are commonplace in life. Fasteners are widely used in many industries and the degree of standardization, serialization and generalization is extremely high.

2023-08-17 13:52:01

Metal stamping machines can be divided into hydraulic presses and mechanical presses, and both are often used in industrial metal forging applications.

2023-08-11 14:45:04

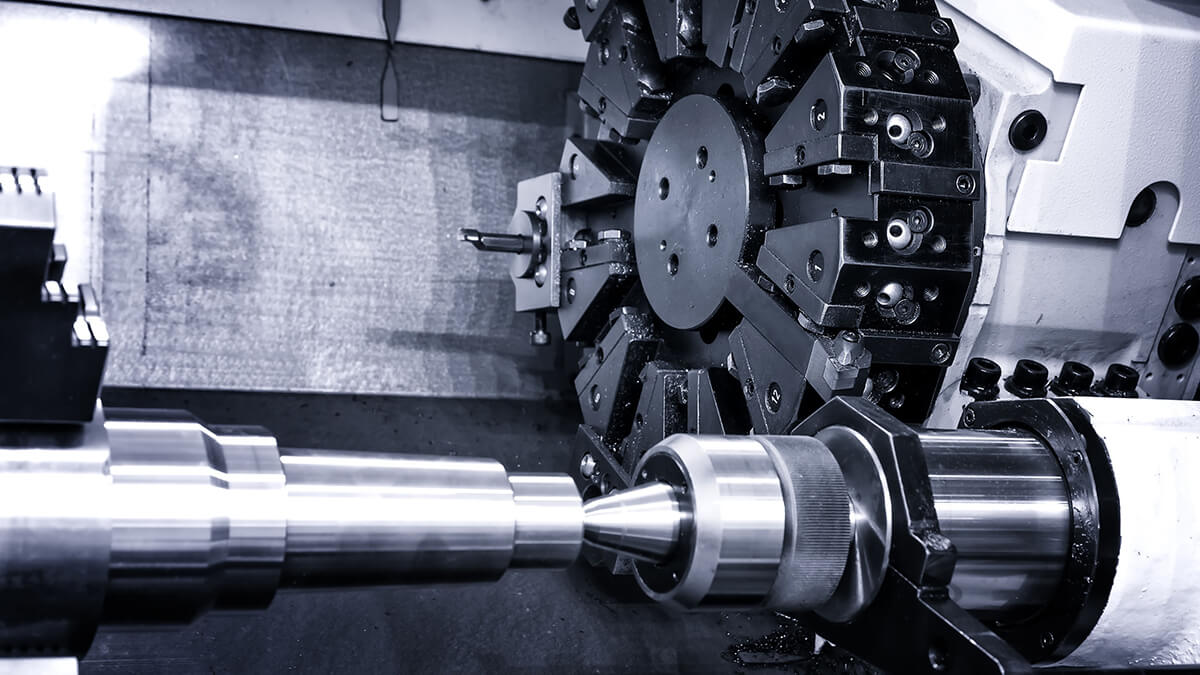

Boring Machine is different from other machine tools and mainly suitable for boring machine processing.

2023-08-11 14:40:04

Saw tool is a common hand tool, divided into hand saws and electric power saws, which facilitates our simple sawing needs. Among them, hand saws are divided into many different types, and suitable hand saw tools can be selected according to different needs.

2023-08-11 14:30:55

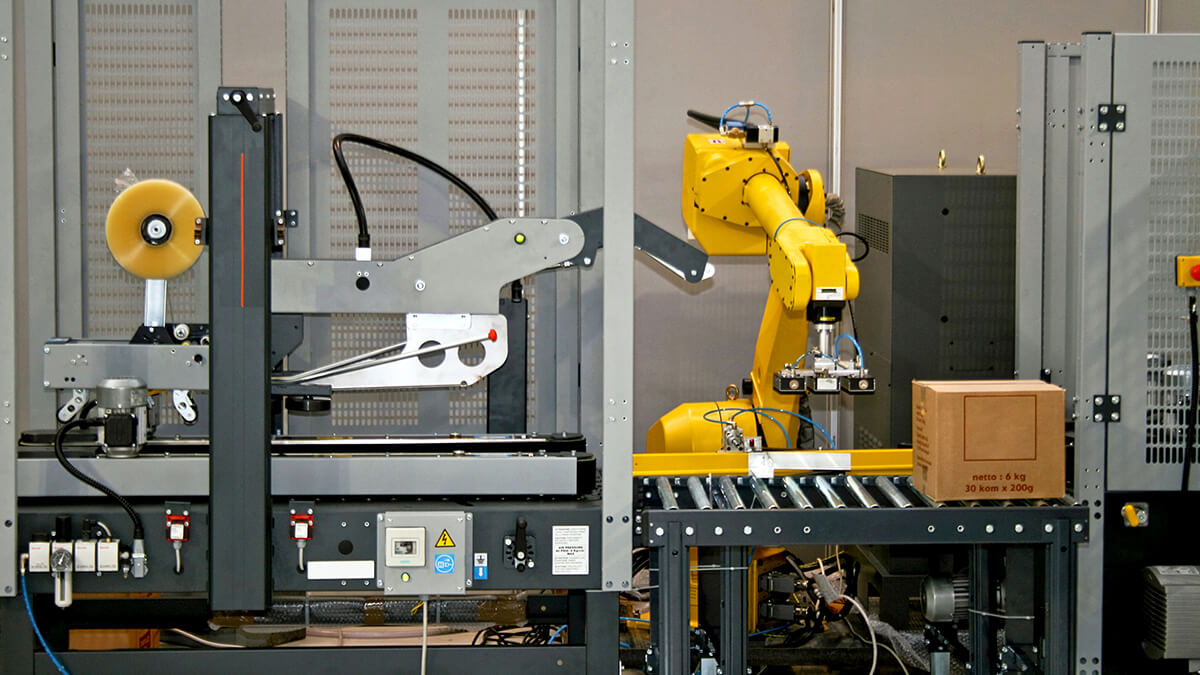

The emergence of automation has had a great impact on many industries. Many highly repetitive factory operations may restrict production capacity. With the introduction of Industry 4.0, various technologies have led to the automation of production lines, from the supplying of raw materials, to assembly, distribution, and packaging. People are taking notice of these very important developments, and this article will explore some of these new forms of automation, and the value they bring.

2023-08-03 10:47:01

Hyperautomation is the use of the power of multiple technologies to achieve end-to-end automation. Hyperautomation is the process of continuously integrating automation into an organization's business processes, combining advanced technologies such as robotic process automation (RPA), artificial intelligence, and machine learning to enhance the results of human work. Not only does it automate key processes, but it also builds an automation ecosystem that finds more processes that can be automated without human intervention.

2023-08-03 10:39:52

Nowadays, the traditional industry combines the technology of the Internet of Things, towards the innovation of Industry 4.0 and the development of intelligent manufacturing.

2023-08-03 10:21:44

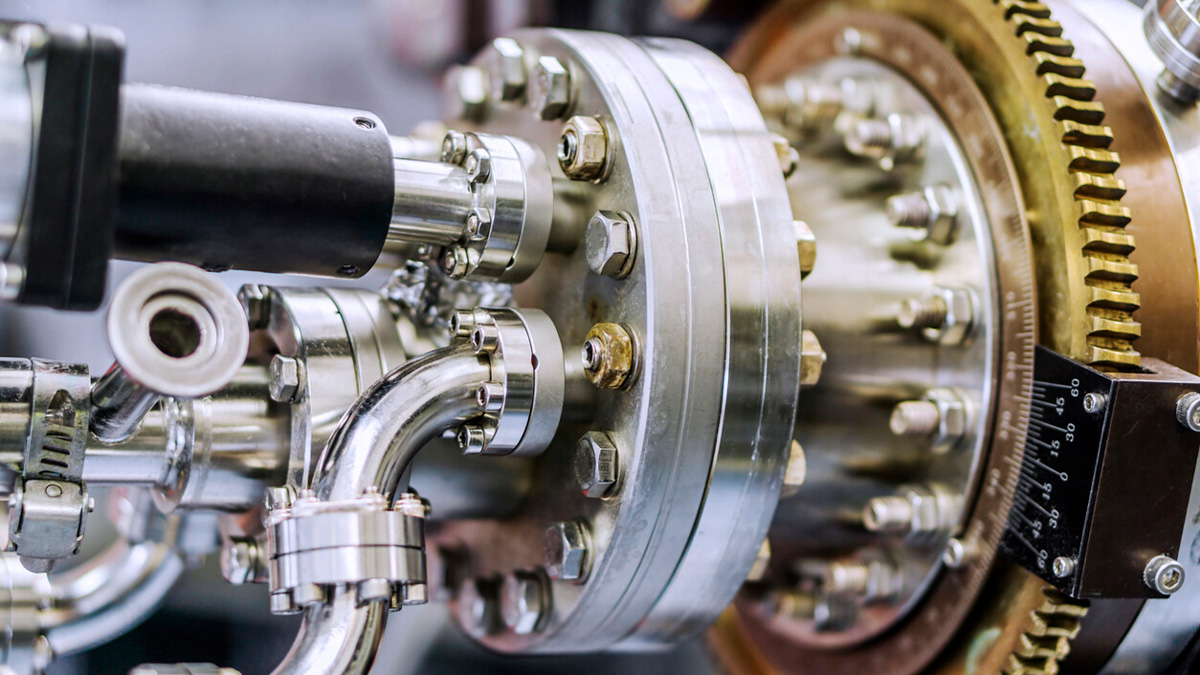

Industrial manufacturing requires machining tolerances. EDM machine can cut metal through electric current.

2023-07-28 11:20:03

Through ultrasonic-assisted processing technology, hard and brittle materials can be processed easily, reducing-edge chipping and improving surface quality.

2023-07-14 13:30:04

Cubic Boron Nitride (CBN) turning tools are tightly sintered from boron nitride and tungsten carbide bases. The hardness of boron nitride is next to PCD. It has excellent chemical stability and will not produce affinity with iron, cobalt, and nickel-based metals. Therefore, it is especially suitable for work hardening steel, with a hardness above HRC45. Chilled cast iron and heat-resistant steel (Inconel) are also suitable.

2023-07-14 13:23:13

Capacitors are used in AC circuits and pulse circuits. In DC circuits, capacitors generally play the role of blocking DC.

2023-07-14 13:19:27

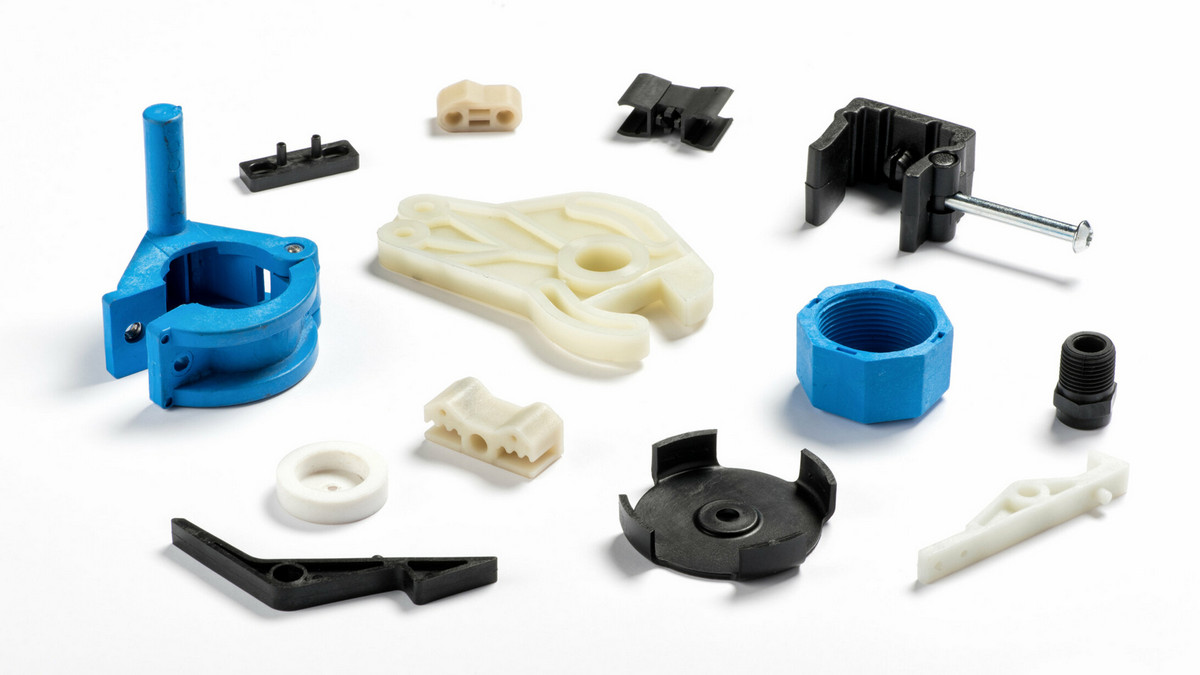

Powder injection molding (PIM), including metal injection molding (MIM) and ceramic injection molding (CIM), is a one-shot molding technology that combines high throughput and high precision. This technology has been widely used in many industries to produce various precision parts.

2023-07-14 13:08:55

Metal Injection Molded (MIM) is a high-tech near-net-shape technology that combines traditional powder metallurgy and plastic injection molding processes.

2023-07-14 13:02:38

The world has entered the era of Industry 4.0. robots assist human manufacturing, emphasizing the use of "human-machine collaboration" to move toward smart production. In recent years, the population aging problem faced by developed countries has caused the production costs of industry and manufacturing to increase year by year. Enterprises have deployed automation equipment to improve production efficiency. Various industries have also undergone tremendous changes in this intelligent wave.

2023-07-07 14:23:36

In the cutting of hardware components, a comprehensive analysis of factors is required, and through strict process flow, a suitable cutting process can be planned to manufacture hardware components of stable quality.

2023-07-07 14:04:12

Green Manufacturing, also known as environmentally conscious manufacturing, is a manufacturing model that considers environmental impact and benefits.

2023-07-07 13:55:25

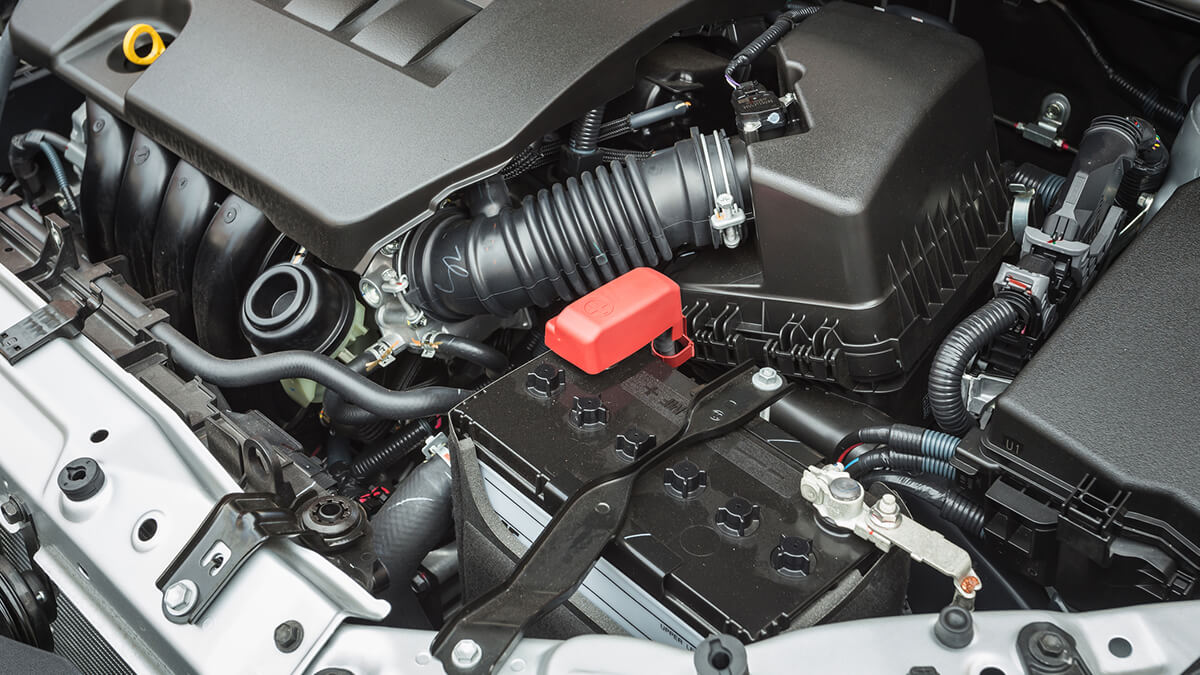

What are the predictive maintenance and preventive maintenance? Predictive and preventive maintenances often include condition monitoring hardware, industrial automation hardware, communication connections, storage and platforms, and data analysis.

2023-07-07 13:46:37

"Efficiency" is the most important key in the pursuit of success in the manufacturing process and the entire industry.

2023-07-07 13:39:07

With the continuous development of the downstream industry of linear actuator and the continuous expansion of linear actuator applications, the global demand for linear actuator has shown a rapid growth. In 2019, the global linear actuator market has exceeded 15 billion yuan.

2023-07-05 11:33:22

Agree