- Showing results for

- Smart Industrial

The traditional manufacturing industry is facing a time when the smart transformation is needed. Through the introduction of intelligent production technology, new industrial development is started.

2020-03-23 16:53:26

In response to the impact of the U.S.-China trade war, Taiwanese machine tool makers are actively entering the European and Southeast Asian markets.

2020-03-24 10:07:34

Taiwanese machine tool manufacturers are aggressively entering Europe, hoping to expand the machine tool market.

2020-03-24 10:30:32

Nowadays, the traditional industry combines the technology of the Internet of Things, towards the innovation of Industry 4.0 and the development of intelligent manufacturing.

2020-03-24 10:44:55

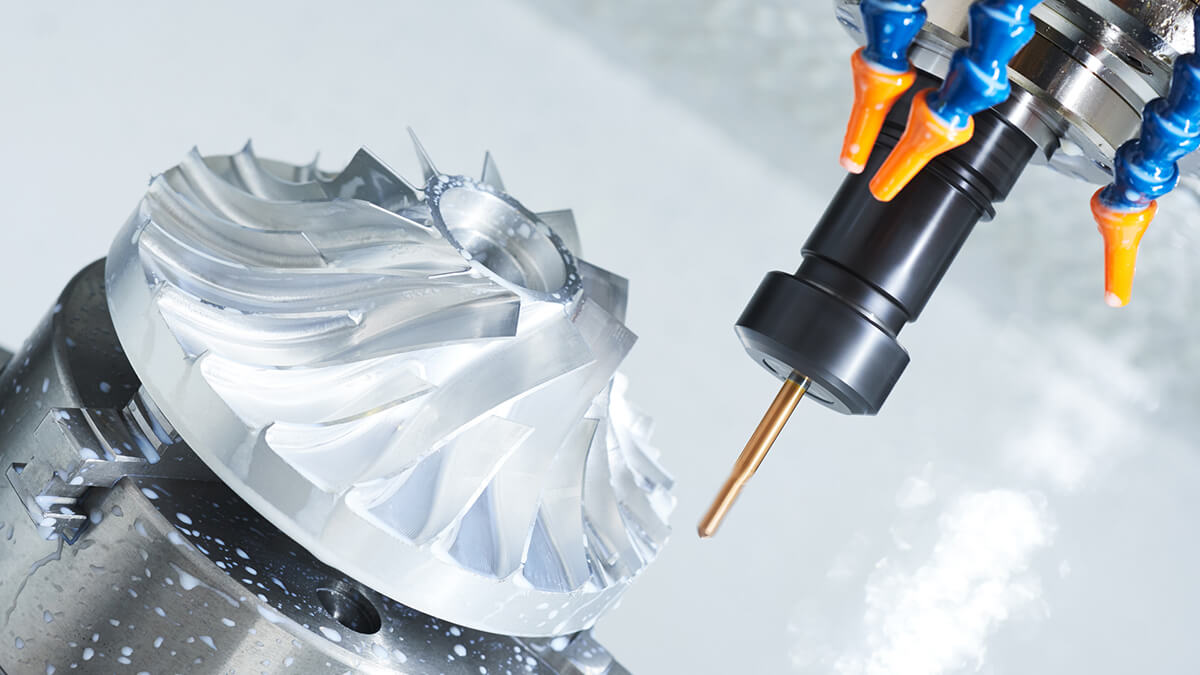

Do you know the new words about tooling 4.0? Here we provide some introduction and example that manufacturers can know and follow the direction. Tooling 4.0 improves all about using technology to turn "clumsy" products into "smart" products.

2020-04-06 14:19:19

With the advent of Industry 4.0, countries have also adjusted their industrial manufacturing strategies to enhance their smart manufacturing capabilities.

2020-04-21 13:09:26

Artificial intelligence illuminates the evolution of IoT and promotes three key application areas.

2020-05-14 15:43:54

Blockchain (or block chain) is a concatenated text record that connects and protects content by cryptography. Each block contains the encrypted hash of the previous block, the corresponding timestamp, and transaction data. This design makes the content of the block difficult to tamper with characteristic.

2020-05-15 17:56:47

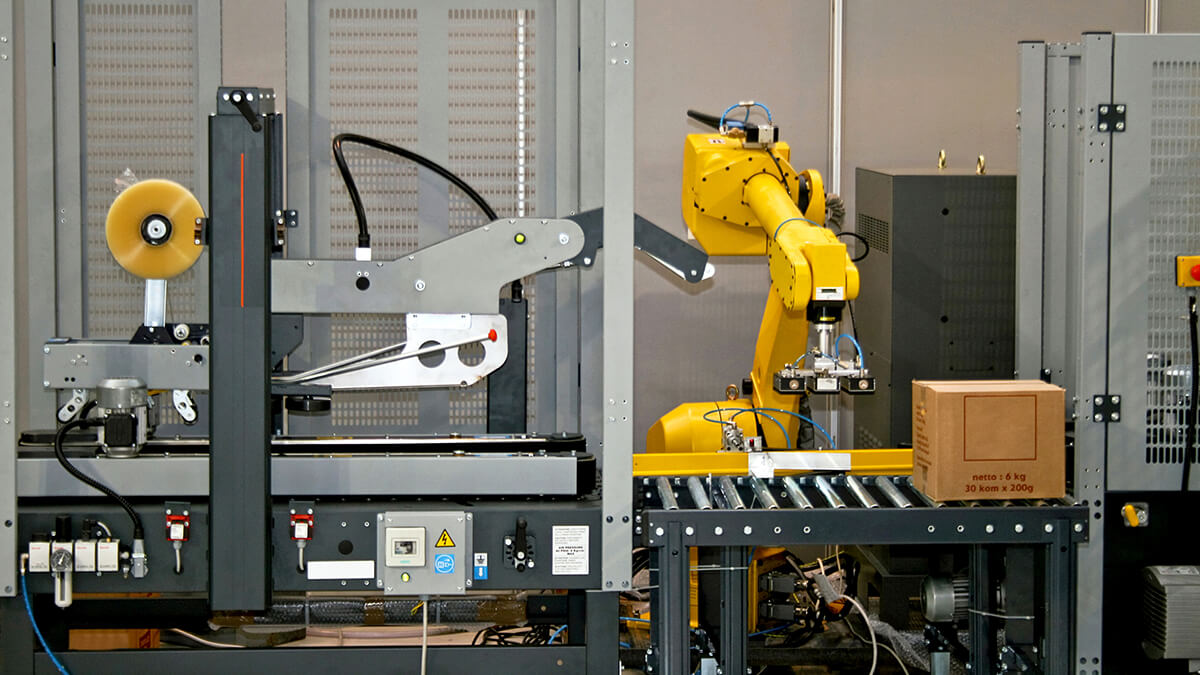

How collaborative robots join production has become a link in the manufacturing chain, improving production efficiency. The small-scale collaborative industrial robot can be operated in a narrower place to solve the problem of working space limitation.

2020-05-21 11:28:57

Industrial robots use a large number of sensors to achieve good operation and control in industrial automation production processes. For example, collaborative robots integrate torque sensors and cameras to ensure the best perspective and safety. What sensors are integrated with industrial robots?

2020-05-21 13:50:03

5G is the engine of Industry 4.0, reshaping the industry! How should Taiwan's manufacturing industry seize the opportunity to upgrade its manufacturing industry?

2020-05-22 14:32:16

5G is regarded as an important promoter of Industry 4.0. 5G's high network speed and low power consumption enable each sensor of the future unmanned factory to be connected to the cloud, further extracting data for analysis, and driving artificial intelligence.

2020-05-25 16:36:52

After "Cloud Computing", a new term "Fog Computing" has been added in recent years. It mainly comes from the phrase "fog is a cloud closer to the ground".

2020-05-29 16:27:48

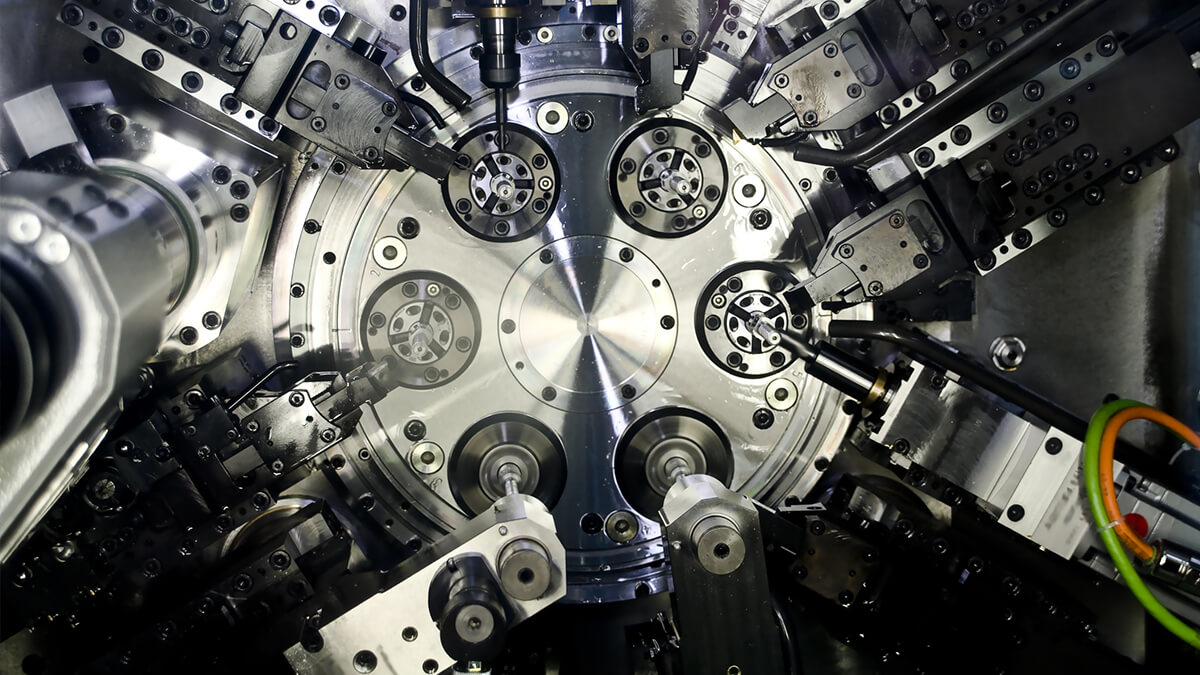

"Link" and "Optimization" are the core spirits of Industry 4.0. To create these two key elements, it requires extensive use of automated production, Internet of Things, intelligent robots, supply chain interconnection, and big data.

2020-06-01 10:32:34

Industrial 4.0 revolution swept through the entire manufacturing industry. Various countries and regions are actively deploying Industry 4.0 and smart manufacturing. How does Taiwan respond? How to combine your own advantages to gain a competitive advantage in this global 4.0 manufacturing revolution? Industrial reform involves not only technology, but also the integration and breakthrough of ideas.

2020-06-03 15:50:55

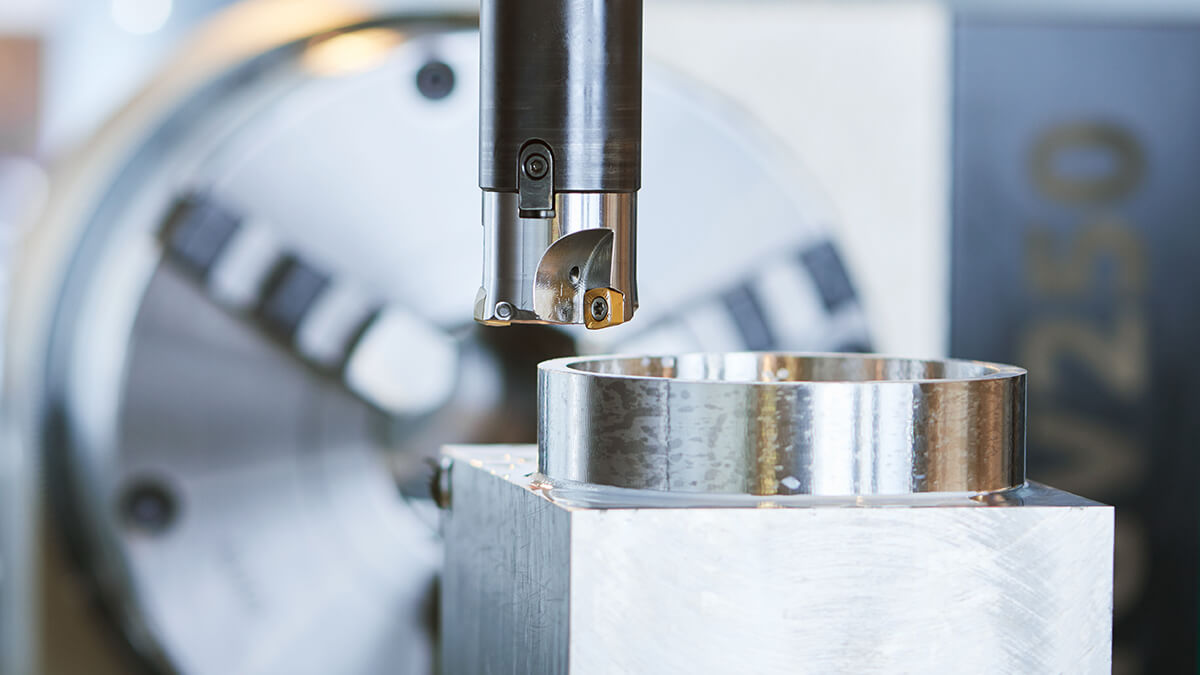

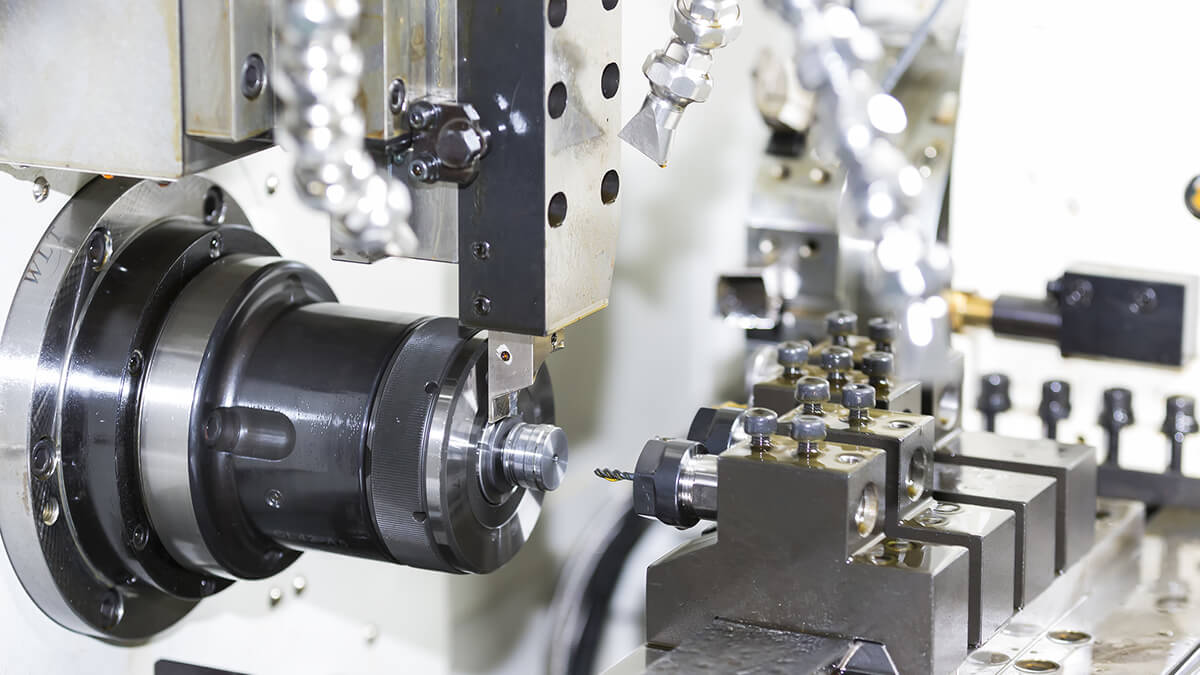

One of the main tenets of Industry 4.0 is data collection. Machine tools will have sensors that will collect many different kinds of data, including data on how much the machine has operated, the conditions it has operated in, and the condition of the components of the tool.

2020-06-05 13:42:46

Smart City refers to the use of various information technologies or innovative ideas to integrate urban constituent systems and services to improve the efficiency of resource utilization, optimize urban management and services, and improve the quality of life of citizens.

2020-06-10 16:20:17

A smart city is to improve the quality of life of citizens through the innovative application of technology, from the early practitioners developed independently, now smart cities are more emphasis on user-centered and build a smart ecosystem.

2020-06-10 16:48:19

"Efficiency" is the most important key in the pursuit of success in the manufacturing process and the entire industry.

2020-06-15 11:10:51

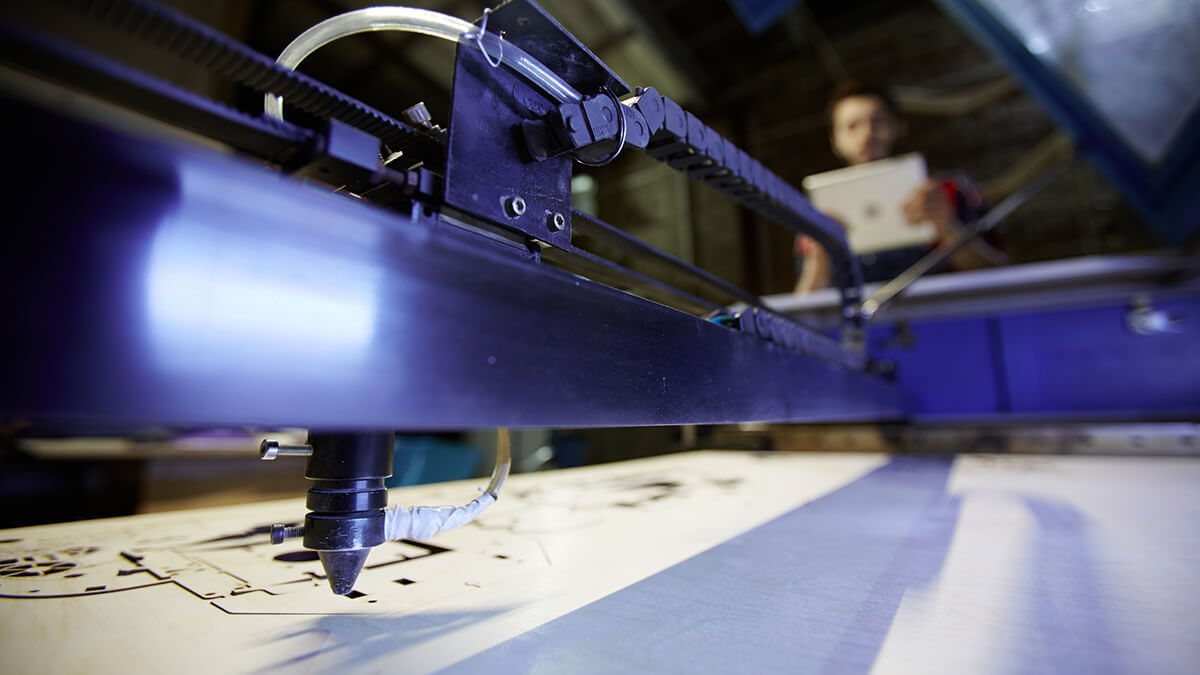

In recent years, with the development of Industry 4.0, factory automation has become a future trend.

2020-06-15 15:38:52

Agree