- Showing results for

- Metal Processing & Equipment

Injection molding machines, also, simply known as injection machines, are special machines for manufacturing plastic products. There are many types of injection molding machines, and they can be classified according to their power mode, mold opening and closing direction, applicable raw materials used, mold clamping structure, and injection structure.

2022-06-28 16:58:53

A grinding wheel is a tool for grinding. It is composed of coarse-grained abrasive compounds bonded together. After forming a solid round object, grinding and abrasive processing can be performed on a grinding machine. Grinding is a commonly used processing method, which can obtain higher workpiece density and surface quality. Different grinding methods will produce different grinding defects. The most influential factor is the grinding wheel.

2022-06-27 13:18:28

Knurling is a mechanical process of rolling patterns on the knobs of metal products or other working surfaces, mainly for anti-skid purposes. And used in many hardware, mold, and mechanical components.

2022-06-24 11:40:15

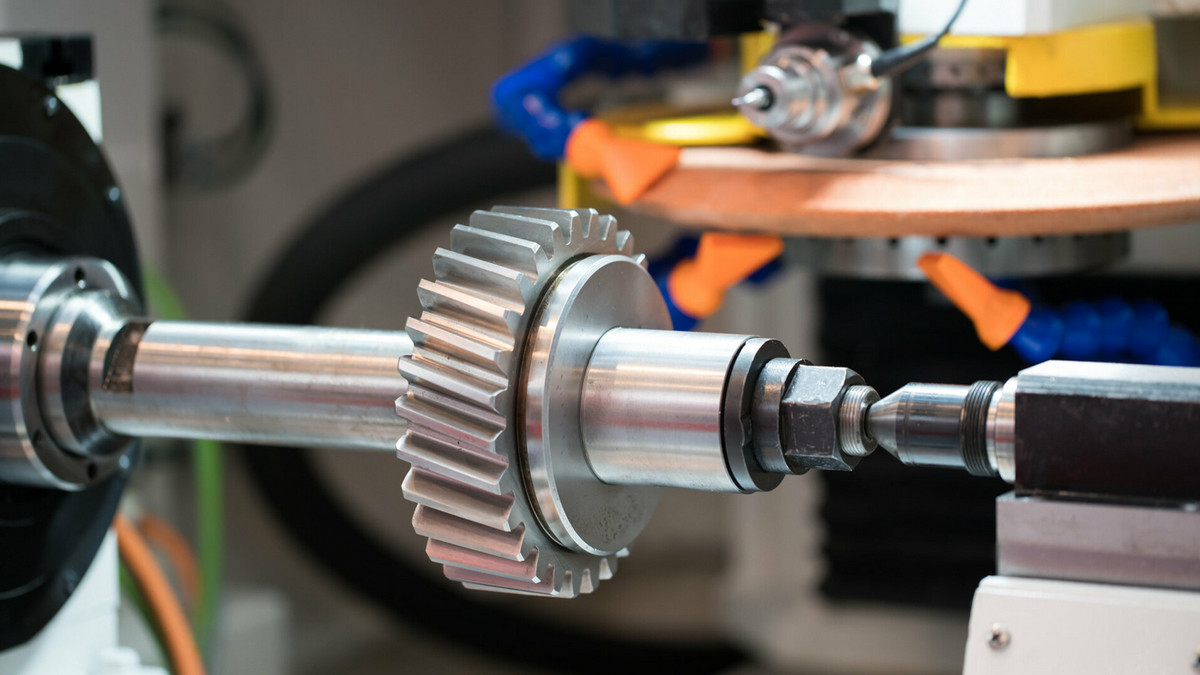

Machine tool is a machine for manufacturing various machines and processing equipment, which occupies a key position in the national industrial development. In response to the global digital transformation, machine tools are also moving towards smart machines.

2022-06-20 09:59:09

Broaching is a machining process that uses a toothed machining tool, called a broach, to cut material from a workpiece. The broach has a series of cutting tips arrayed in sequence on one tool. The cutting tips become progressively larger across the span of the tool. Across the span of the broach, the cutting tips will progress from rough cutter tips to fine cutter tips. The broach is inserted into a machine called a broaching machine, which drives the broach.

2022-06-17 10:31:09

From traditional machinery manufacturing, to the production of high-tech semiconductors, electric vehicles, and drones, nearly all key components require heat treatment.

2022-06-10 09:53:50

Powder metallurgy uses metal powder as raw material, and forms it into a desired shape using a special processing technology. This processing technology is very similar to that used in the production of ceramics, so powder metallurgy techniques can also be used for the preparation and production of ceramic materials. This article will introduce the relevant technology of the powder metallurgy process in detail, and help the reader understand the advantages and disadvantages of the powder metallurgy process.

2022-06-06 15:45:26

Modern manufacturing is developing in the direction of high efficiency, high precision, and economy. Band saws are the most efficient tools for the primary processing of metal and non-metal materials.

2022-06-06 15:13:02

Direct Energy Deposition (DED), also known as metal laser cladding, is one of the methods used to fabricate metal workpieces by additive manufacturing technology.

2022-05-18 16:10:03

A hydraulic press is a machine that uses hydraulic pressure to process metal, plastic, rubber, wood, powder, and other products. It is commonly used in pressing processes and press forming processes.

2022-05-13 11:33:13

Metal spraying is the process that uses compressed air or inert gas to spray molten, corrosion-resistant metal onto a metal surface to form a protective coating.

2022-05-04 11:13:35

Thermoforming or vacuum forming is a common method of processing plastic materials, and vacuum formed products are ubiquitous in daily life. The process involves heating a plastic sheet until soft and then placing it over a mold. A vacuum then draws the soft sheet into the mold. The sheet is allowed to cool and is then removed from the mold.

2022-05-04 09:30:12

Polishing refers to the use of mechanical, chemical, or electrochemical action to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. It includes the modification of the surface of a workpiece using polishing tools and abrasive particles or other polishing media.

2022-04-27 14:16:43

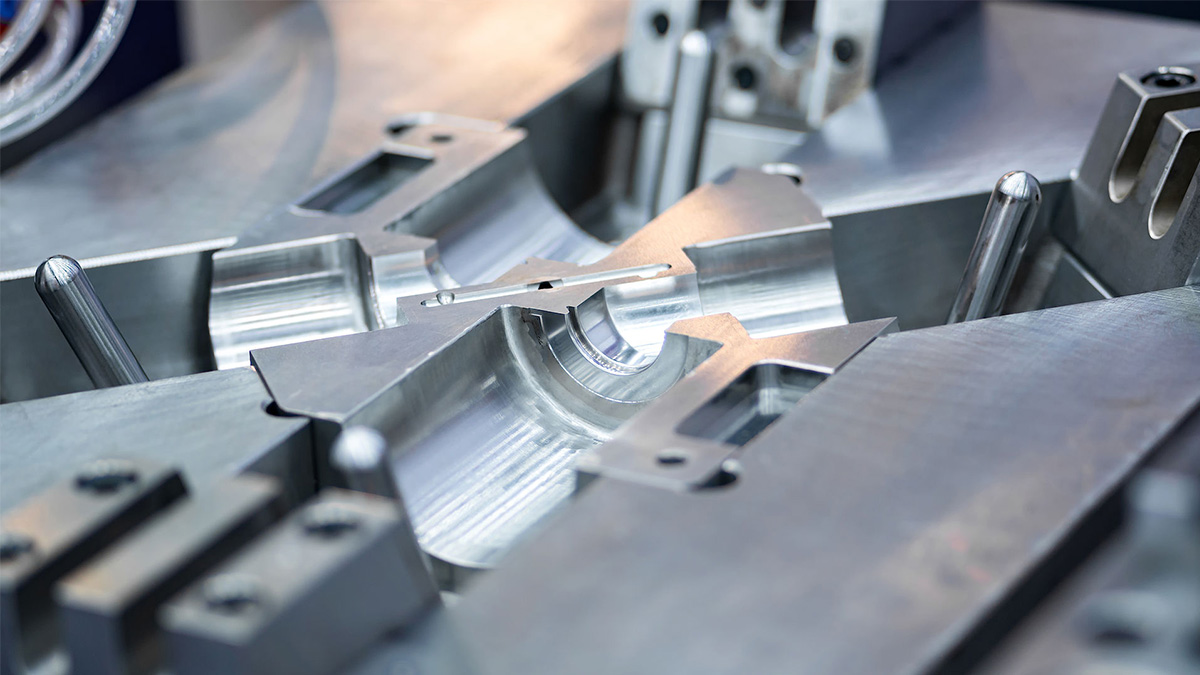

Casting is most commonly used to create complex shapes that would otherwise be difficult or uneconomical to make using other methods. Metal casting processes have been known for thousands of years, and have been widely used for creating sculptures, jewelry, transportation, weapons, and tools.

2022-04-25 14:39:24

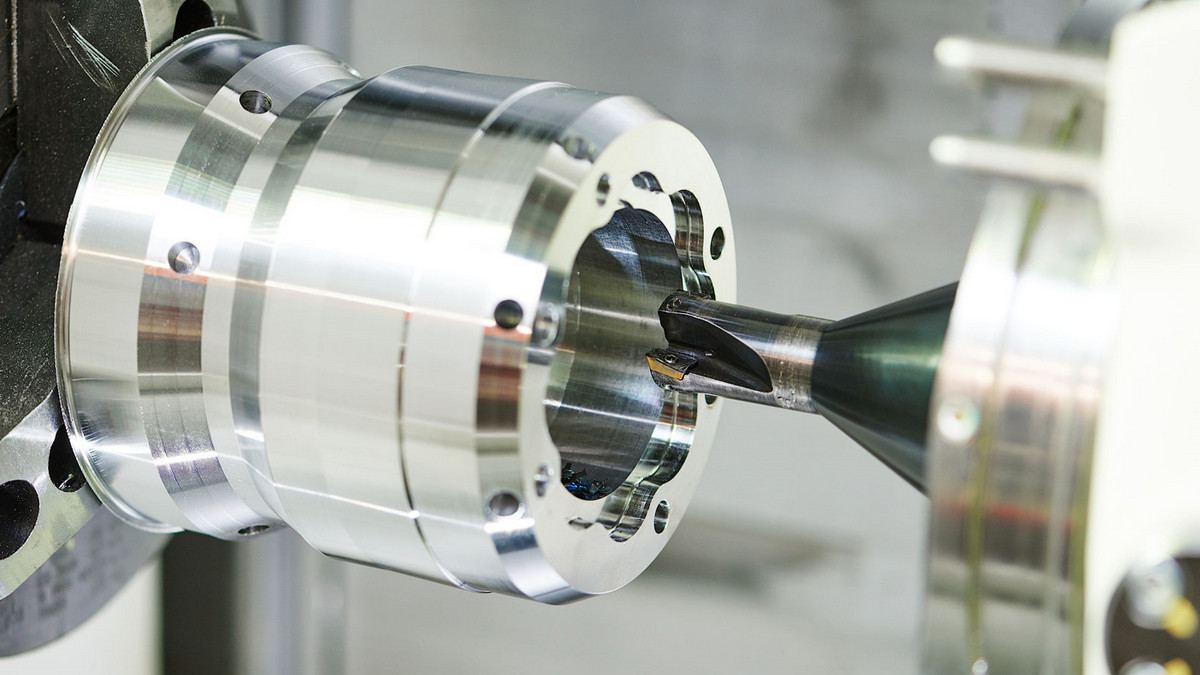

In the machining process, as the tool cuts off the unnecessary material from the workpiece, a cutting force will be generated on the workpiece. To resist the cutting force and allow the cutting process to be completed, the workpiece must be firmly clamped on the machine tool. The device that positions and clamps the workpiece is called a fixture. The device that holds and guides the cutting tool is called a jig.

2022-04-19 11:04:42

Titanium alloys are widely used in aerospace, chemical, marine, and automotive industries due to their excellent strength-to-weight ratio, corrosion resistance, and ability to maintain strength at high temperatures. However, the disadvantages of titanium alloys are poor thermal conductivity and strong reactivity with tool materials. Their high strength, and low elastic modulus make them difficult to cut materials.

2022-03-21 10:47:12

Etching is a technique to process the surface of the object by using chemical strong acid corrosion, mechanical polishing, or electrochemical electrolysis. In addition to enhancing aesthetics, it furthermore increases the added value of the object. Procedures from traditional metal processing to high-tech semiconductor manufacturing are all within the scope of applications of etching technique.

2021-08-27 17:04:45

Welding is a technique and process for joining metals or other thermoplastics by heating or pressing.

2021-08-27 11:40:42

Low-temperature treatment is a sub-zero process, which is carried out immediately after quenching and is carried out by continuous tempering. The ultra-cold treatment has a significant improvement in the wear strength of the workpiece and has a breakthrough benefit for the stability of the mold size.

2021-05-05 19:06:21

Metal fabricators looking to take on finishing should know about two of the most common finishing alternatives—liquid and powder coating—and the requirements involved for a company hoping to apply one or both.

2020-10-20 16:24:45

Agree