- Showing results for

- Metal Processing

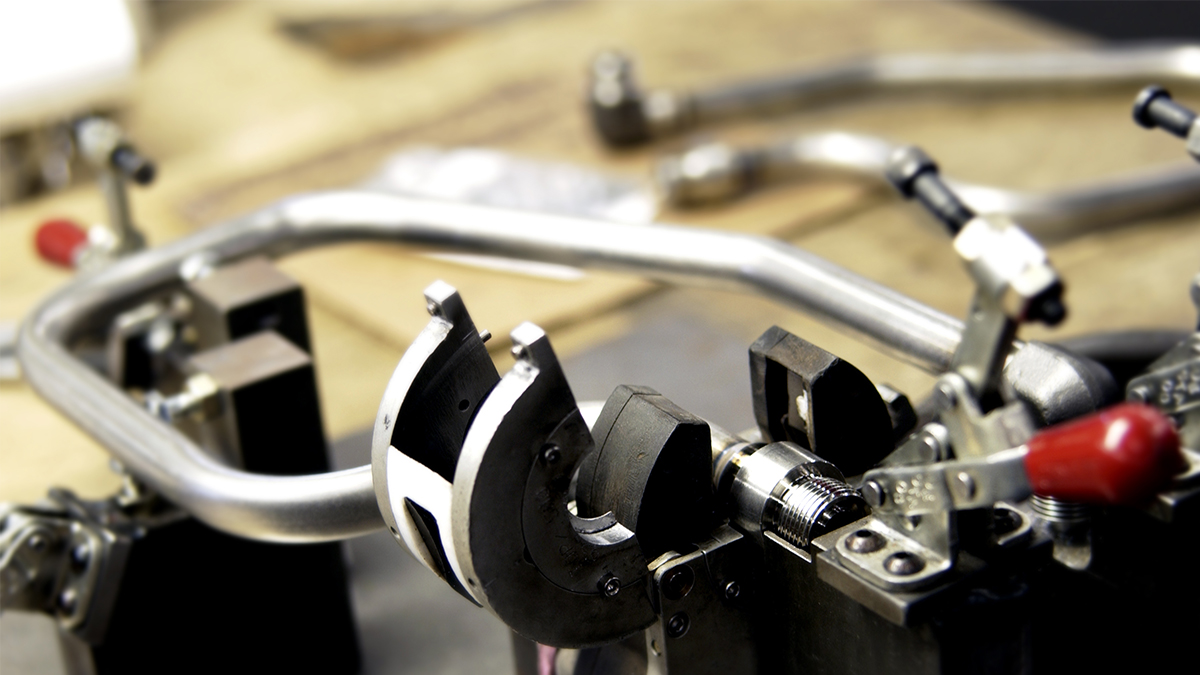

Industrial manufacturing requires machining tolerances. EDM machine can cut metal through electric current.

2020-03-23 11:27:41

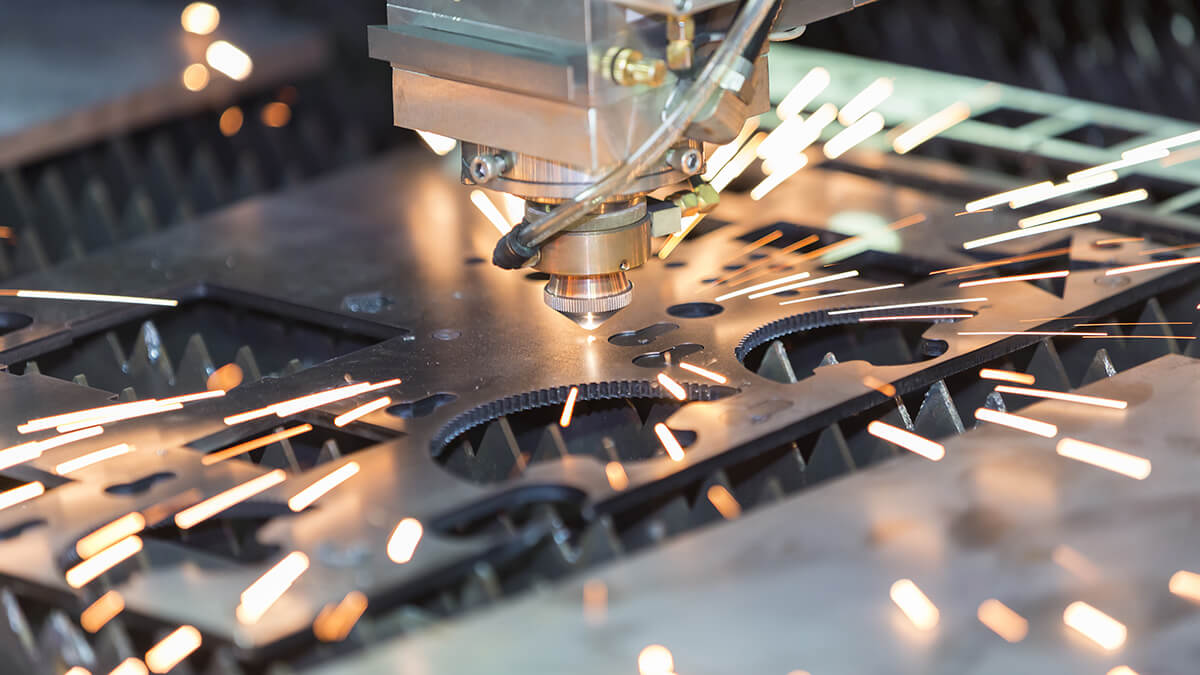

Cutting technology has many different processing techniques, and laser cutting can perform more complex and precise cutting requirements, which is also a common processing technique in industrial manufacturing.

2020-03-23 15:11:07

Anodizing is a process of surface treatment. The final process of metal manufacturing is surface finishing, anodizing precision machined metal parts, a reliable and relatively inexpensive method to improve wear resistance and coloring aluminum and other non-ferrous metals.

2020-05-12 11:22:20

Generally used for cold processing and a part of the machine used for hot processing can be called press.

2020-05-12 13:18:28

It is inevitable that there will be some defects in the reprocessing process of metal-related mechanical equipment or parts. Therefore, the surface processing procedure of the last item is very important, and the function of surface beautification and protection is carried out, thereby improving the performance of metal parts and avoiding rust.

2020-05-12 16:45:12

Stamping is a process in which thin walled metal parts are shaped by punches and dies.

2020-05-28 09:40:25

In the field of manufacturing processing, common processing methods include broaching, boring, grinding, milling, etc.

2020-06-08 11:06:20

Welding is a method to make two metal blocks belong together. Metal weldability is the ability of metal materials to adapt to the welding process. Under certain welding process conditions, whether it can obtain high-quality welded joints and whether the welded joints can operate safely under use conditions is an evaluation standard.

2020-07-09 13:28:57

Welding is a process that uses "heat" and "electricity" to connect two pieces of metal, and the type of welding metal will also affect the welding results and technical requirements; like many professional skills, welding technology also has different levels of difficulty. First understand the most common types of welding introduction, principle teaching, and skill analysis.

2020-07-09 14:35:48

The thread is usually the last feature added to the part. There are other challenges besides the exact parameters required and standard threading issues.

2020-07-29 11:22:50

Metal stamping refers to the use of the power of punching machinery and the use of molds as metal plate forming tools to produce punching separation or plastic deformation effects to achieve the production technology of parts in terms of size, shape, and performance requirements.

2020-10-05 11:32:57

Metal fabricators looking to take on finishing should know about two of the most common finishing alternatives—liquid and powder coating—and the requirements involved for a company hoping to apply one or both.

2020-10-20 16:24:45

Etching is a technique to process the surface of the object by using chemical strong acid corrosion, mechanical polishing, or electrochemical electrolysis. In addition to enhancing aesthetics, it furthermore increases the added value of the object. Procedures from traditional metal processing to high-tech semiconductor manufacturing are all within the scope of applications of etching technique.

2021-08-27 17:04:45

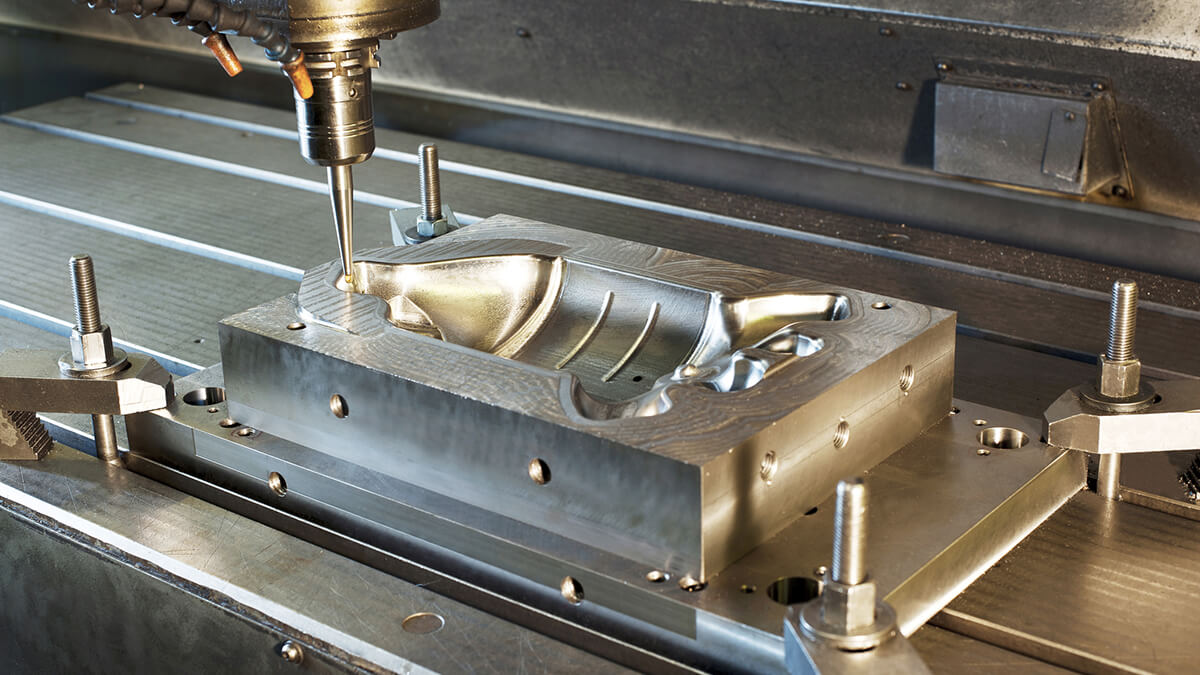

In-mold manufacturing, casting and forging are often used for processing. What is the difference between these two manufacturing processes?

2022-02-10 17:07:49

Titanium alloys are widely used in aerospace, chemical, marine, and automotive industries due to their excellent strength-to-weight ratio, corrosion resistance, and ability to maintain strength at high temperatures. However, the disadvantages of titanium alloys are poor thermal conductivity and strong reactivity with tool materials. Their high strength, and low elastic modulus make them difficult to cut materials.

2022-03-21 10:47:12

Spot welding is a type of welding used to weld sheets of metal together by clamping the sheets together at a single point and passing an electric current through the point to melt the sheets together.

2022-03-21 13:57:33

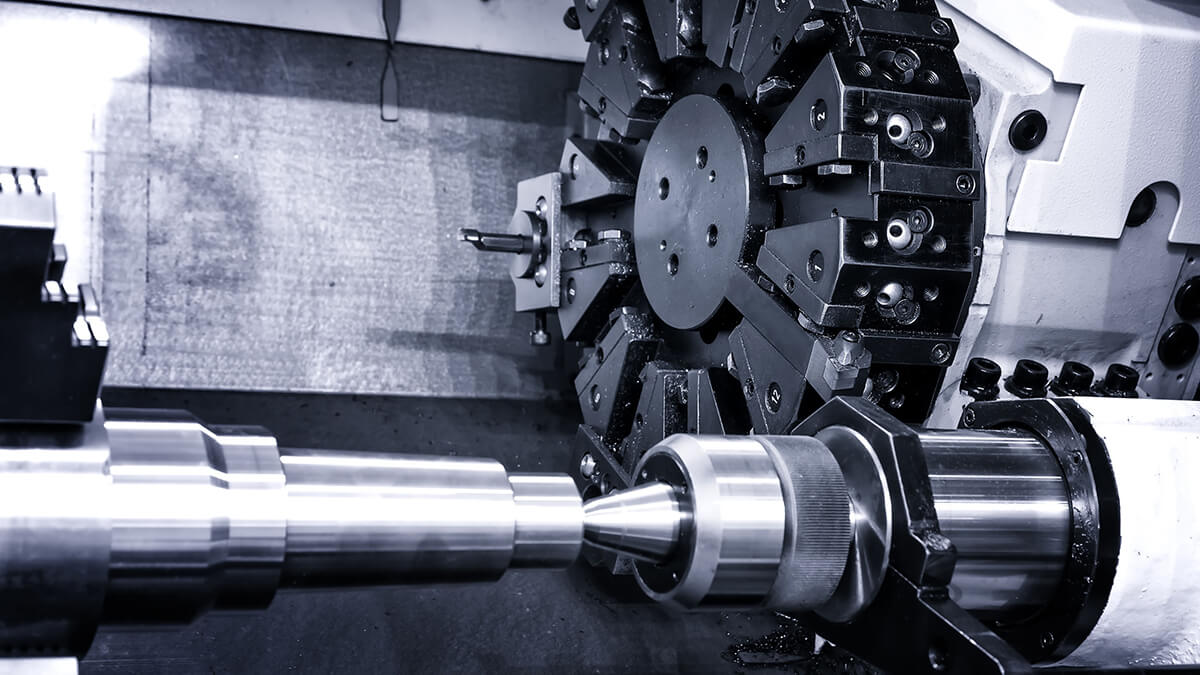

Machining is one of the most important cutting process used in any manufacturing industry. There are many different processing methods and each of these methods may require the use many different cutting tools. With each tool corresponding to a different cutting process, often problems can occur which not only affect the machining accuracy, but also the quality of the workpiece, and can even cause accidents. Understanding the cutting processes, machine tools used, and factors affecting accuracy are important for avoiding problems. Understanding the basics of cutting processing and smart tools will make your machining more effective and require less effort.

2022-04-13 10:38:50

Polishing refers to the use of mechanical, chemical, or electrochemical action to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. It includes the modification of the surface of a workpiece using polishing tools and abrasive particles or other polishing media.

2022-04-27 14:16:43

Metal spraying is the process that uses compressed air or inert gas to spray molten, corrosion-resistant metal onto a metal surface to form a protective coating.

2022-05-04 11:13:35

Direct Energy Deposition (DED), also known as metal laser cladding, is one of the methods used to fabricate metal workpieces by additive manufacturing technology.

2022-05-18 16:10:03

Agree