- Showing results for

- Metal Processing & Equipment

A grinding machine, or grinder is a widely used abrasive processing process in which a spinning wheel is covered with coarse grains. Cutting pieces of metallic or non-metallic substances from a workpiece to make the surface flat or smooth.

2023-04-12 13:31:11

Ultra-precision machining technology is an important way to improve the performance, quality, service life and reliability of electromechanical products, as well as saving materials and energy. For example: improving the machining accuracy of cylinders and pistons can improve the efficiency and horsepower of automobile engines and reduce fuel consumption; improving the machining accuracy of rolling elements and raceways of rolling bearings can increase the speed of bearings, reduce vibration and noise; improve flatness of processing of magnetic disks, thereby reducing the gap between it and the magnetic head, can greatly increase the storage capacity of the magnetic disk; improving the marking accuracy of the semiconductor device (reducing the line width, increasing the density) can improve the integration of the microelectronic chip, etc.

2023-04-12 13:24:51

A stamping press machine is a machine that can process sheet metal into the desired shape. It is commonly used for metal stamping to convert a flat metal sheet into a specific shape. What are the types of punching machines? Let's dig it out!

2023-02-10 08:58:40

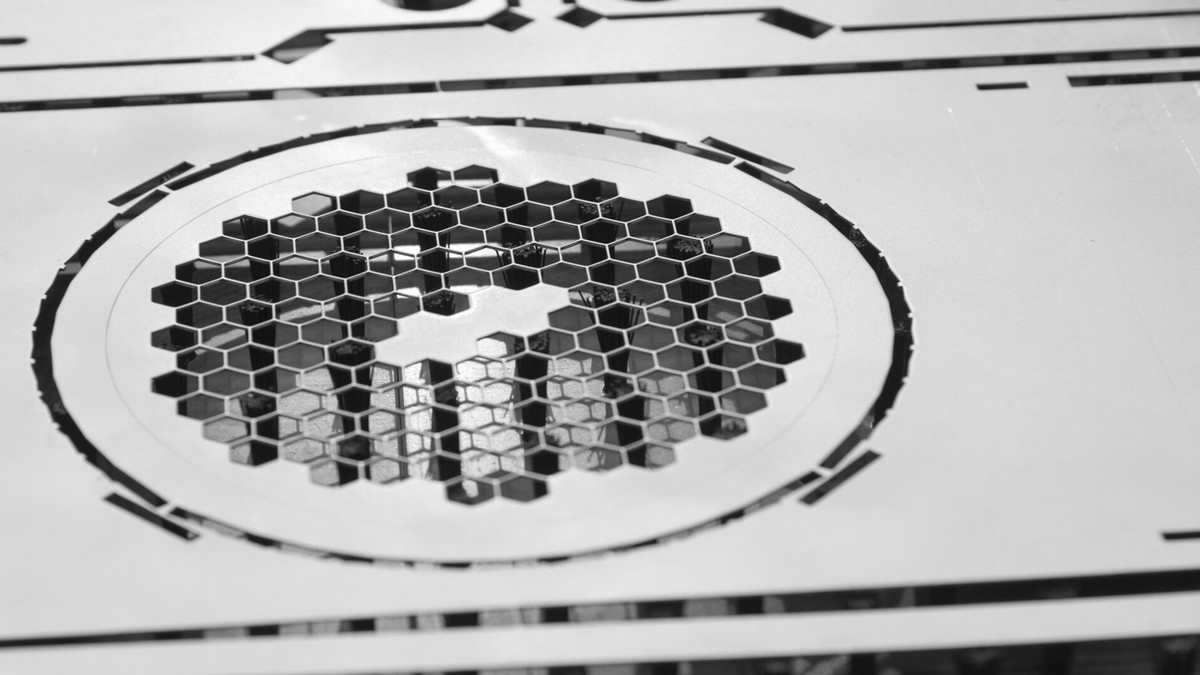

Heat-Assisted Magnetic Recording (HAMR) is a technology that uses laser heat to first heat highly stable media to assist in the magnetic recording of data.

2023-01-16 15:14:42

"Sheet metal" in sheet metal processing refers to thin metal plates, which can be processed by stretching, stamping, bending, etc., and the thickness is usually less than 6mm. Common materials include iron plates (black steel SPHC, cold-rolled steel SPCC, galvanized steel SECC), hot-dip galvanized steel sheet SGCC), stainless steel (SUS304, SUS316), aluminum (AL5052), copper, etc. Sheet metal processing is different from other processing technologies. It includes many different steps, such as: laser cutting, NCT punching, cutting, folding, welding, riveting, etc. The specific products produced are usually support frames, equipment covers, internal parts and some functional objects, such as electronic control panels, medical equipment covers, airport automatic clearance machine covers or parts, snapshot cabinets, food processing equipment covers and parts.

2023-01-12 16:29:13

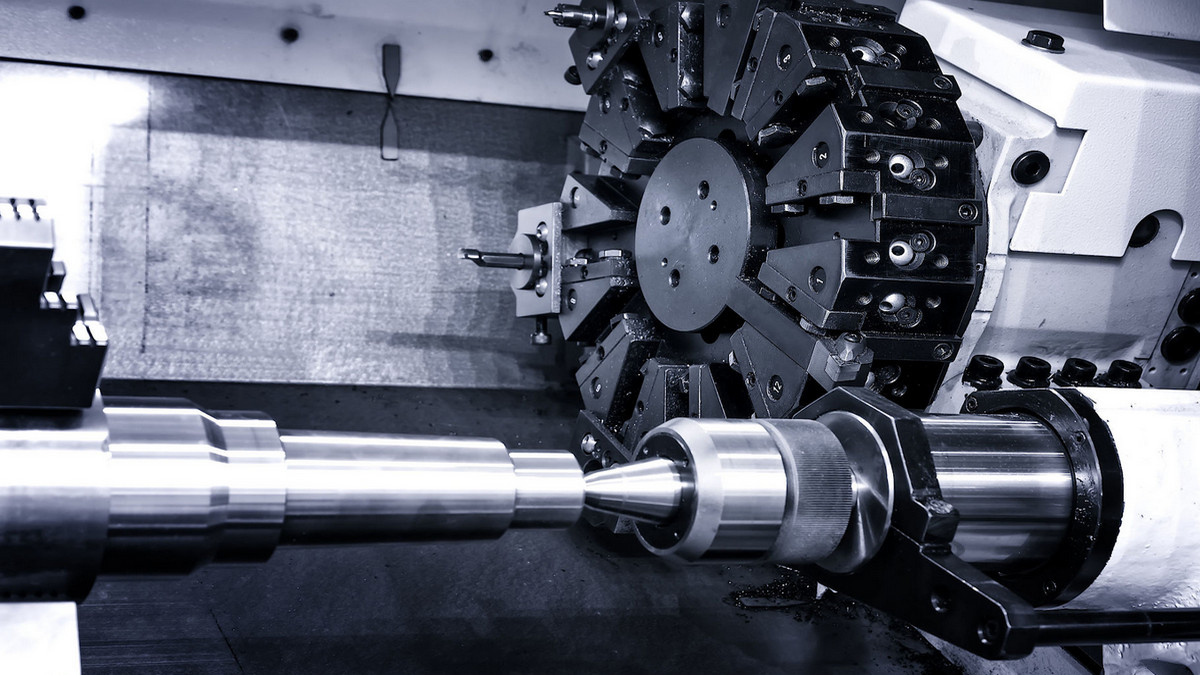

The shaft in a machine tool is the axis of rotation in it, and most likely there will be a drive shaft in it.

2023-01-12 15:41:43

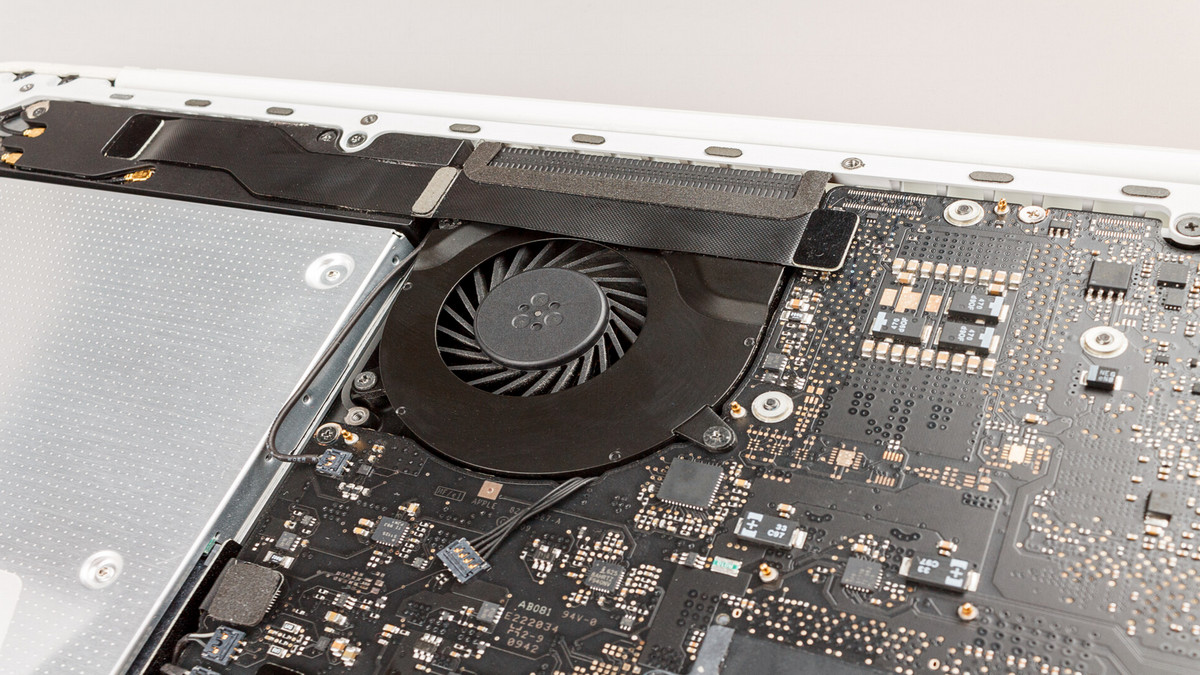

A cooler is a device used for cooling during the manufacturing process.

2023-01-12 11:13:39

Anodizing is a treatment used to enhance the surface properties of metals. It can improve the appearance, durability, conductivity or other properties of a metal surface and help protect it from wear and corrosion. In addition, it can also be used to make different shaped materials, such as rubber rings, pressure-type parts or trimming cutting tools. Therefore, anodizing is a common metalworking method.

2023-01-06 11:48:17

Welding is a manufacturing process and technology that uses heat, high temperature or high pressure to join metal or other thermoplastic materials such as plastics. According to the state of the metal in the welding process and the characteristics of the process, the welding methods can be divided into three categories: welding, pressure welding and braze welding.

2023-01-04 15:45:49

A worm gear is a gear consisting of a shaft with a helical thread that meshes with and drives the gear.

2023-01-04 15:21:29

In the chip formation process, materials are cut through mechanical means by using tools like milling cutters, saws, and lathes. It is an integral part of the engineering of developing machines and cutting tools.

2023-01-03 10:25:35

A grinder is a widely used abrasive processing process in which a spinning wheel is covered with coarse grains. Cutting pieces of metallic or non-metallic substances from a workpiece to make the surface flat or smooth.

2022-12-28 17:14:24

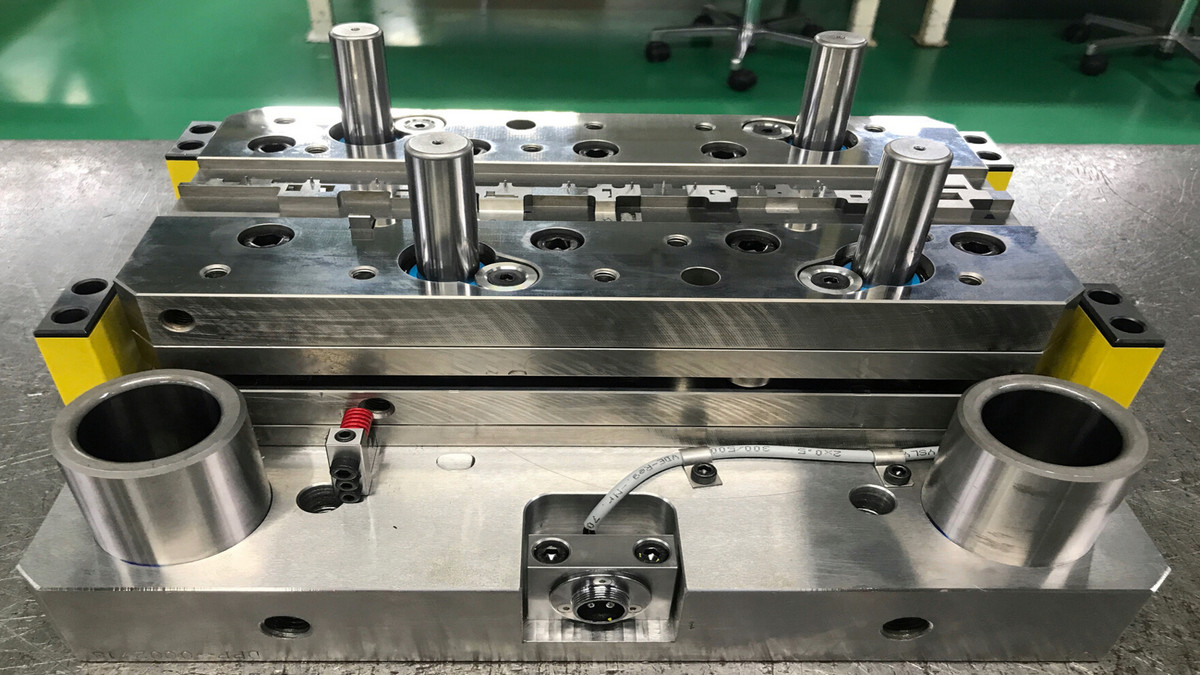

Die casting is a manufacturing process in which molten metal is injected into a mold cavity under high pressure and then cooled to form a part. It is often used for producing parts with complex shapes, intricate details, and thin walls. Die cast parts are usually made from metals such as aluminum, zinc, copper alloys, magnesium, lead or tin-based alloys.

2022-12-28 13:55:55

In order to make metal workpieces have the required mechanical properties, physical properties and chemical properties, besides reasonable selection of materials and various forming processes, heat treatment processes are often essential. Heat treatment generally does not change the shape and overall chemical composition of the workpiece, but imparts or improves the performance of the workpiece by changing the microstructure inside the workpiece or changing the chemical composition on the surface of the workpiece. Its characteristic is to improve the internal quality of the workpiece, and its function is to improve the mechanical properties of the material, eliminate residual stress and improve the machinability of the metal.

2022-12-13 15:33:44

Metalworking is the production activity of applying various processes to metallic materials to manufacture desired parts, assembly line components or overall large structures. Do you know what metal processing is? The process of metal processing is roughly divided into three categories, namely metal forming, metal cutting and metal joining. This article will give a further introduction to metal cutting.

2022-12-12 15:17:20

Stainless Steel is the abbreviation of stainless acid-resistant steel, and the steel grades that are resistant to air, steam, water, and other weak corrosive media or have stainless properties are called stainless steel. The steel that is resistant to chemical corrosion is called acid-resistant steel.

2022-12-12 14:35:26

Through ultrasonic-assisted processing technology, hard and brittle materials can be processed easily, reducing-edge chipping and improving surface quality.

2022-12-08 14:47:34

Lasers are used in a wide range of industries, especially in processing. The entire laser processing industry is currently moving in the direction of high power, ultra-short pulse, and intelligence.

2022-12-07 14:41:24

The aerospace industry has always been a key development industry in all countries in the world. In addition to strict quality system certification and highly complex integration technology, it also has the characteristics of high added value and high industry relevance, which makes all countries take the development of the aerospace industry as a national industry.

2022-11-28 16:34:34

Sintering refers to the transformation of powdery materials into dense bodies, which is a traditional process.

2022-10-25 16:23:50

Agree