- Showing results for

- Asia Pacific

Are U.S.-China Trade War and COVID-19 influence business opportunities in the United States? The United States is the second-largest consumer of machine tools in the world, the industrial market is still waiting, and global economic demand has not significantly recovered.

2020-03-25 09:00:58

Global automakers are out of material and shut down, this year's machine tool exports fear a decline of more than 10%.

2020-04-06 16:18:54

With the advent of Industry 4.0, countries have also adjusted their industrial manufacturing strategies to enhance their smart manufacturing capabilities.

2020-04-21 13:09:26

In the first quarter of 2020, Taiwan's machinery industry was affected by the outbreak of scheduled epidemics, and machinery export orders fell.

2020-04-27 10:52:09

In March 2020, Japan's export and machine tool market decreased compared with the same period last year, and the market performance did not meet expectations.

2020-05-08 14:04:49

In the field of manufacturing and supply chain, the technical assistance of Industry 4.0 and 5G and AI, combined with blockchain, can promote the new development of manufacturing and achieve more effective integration of hardware, software and services.

2020-05-15 15:48:34

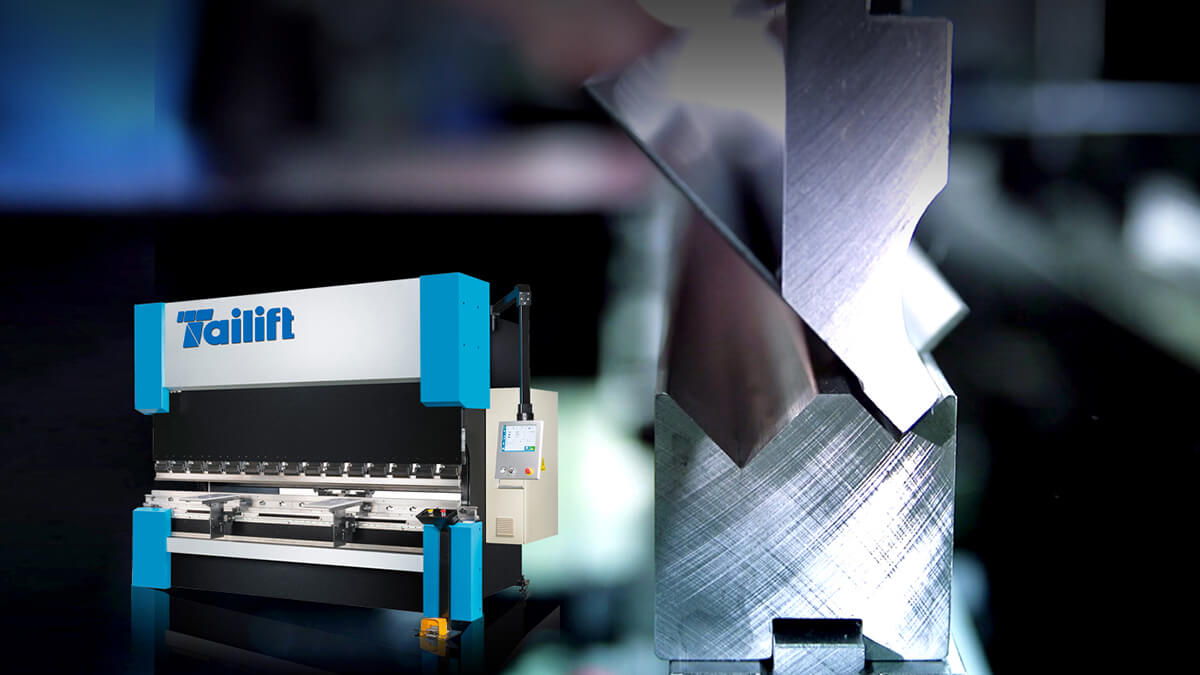

Machine tools can be said to be the mother of various industries, and countries have different marketing strategies based on their production manpower and resources.

2020-05-20 13:53:12

The Indian government vigorously promotes the development of the machine tool market. India is the third largest economy in Asia and has unlimited market demand potential.

2020-05-26 11:08:13

China's component industry is developing rapidly and the domestic demand market is huge, but overall, there are still problems to be solved. To improve the innovation of China's auto parts industry, the technical added value of products, the direction and investment of scientific proportion R & D, the coordination of zero-zero relationships, and the standardization of market operations are all important issues that companies need to jointly solve.

2020-05-26 15:11:31

Japanese machine tool factory develops next-generation business opportunities, demands for replacement machines and introduces 5G services.

2020-05-28 09:06:58

With the implementation of the import substitution policy in Russia, the output of machine tools has increased, and the replacement of equipment has become one of the priority projects of Russia's "development strategy for the machine tool industry before 2030", which will inject huge business opportunities for the Russian machine tool industry.

2020-06-01 09:45:04

The advent of the Industry 4.0 era, coupled with the continued fever of the China-US trade war, has driven Taiwan's manufacturing industry to transform its digital manufacturing into smart manufacturing through digitalization and intelligentization. However, there are four major challenges encountered during the transformation process, and finding a solution to the practice will be the key to the company's victory.

2020-06-01 17:16:40

To understand the needs of Russia's manufacturing upgrading at this stage, and point out that international machine tool manufacturers are launching machine tools in the Russian market that are similar to Taiwan machine tool to provide a reference for Taiwan's machine tool industry to lay out the Russian market.

2020-06-02 14:07:18

The epidemic severely hurts the global economy and the manufacturing industry in Asia is at a bottom.

2020-06-15 10:06:09

In recent years, with the development of Industry 4.0, factory automation has become a future trend.

2020-06-15 15:38:52

The revenue of the laser industry grows higher and higher in recent years. As manufacturing industry moves toward smart, intelligence and systematization, the laser manufacturing process has become an indispensable role in the manufacturing industry.

2020-06-17 11:27:03

Although the recent impact of the COVID-19 (New Coronary Pneumonia) epidemic caused a short-term loss in the aviation industry, for the overall aviation market, the demand is still constant.

2020-07-06 14:38:57

The ASEAN countries' economy is growing stronger, and it is expected to leap into the world's fourth-largest economy in 2030. Taiwan has geographical advantages and is actively developing a south-facing economic island chain.

2020-07-06 17:21:49

Industry 4.0 has brought about changes in production logic. Through cloud technology and the use of big data, it is possible to monitor the entire production process, automatically detect problems and eliminate obstacles, and at the same time be able to accurately produce and schedule resources, reduce costs and waste of resources, and achieve the most efficient Production. In the future, the new trend of Industry 4.0 will tend to analyze huge amounts of data and manufacture customized products close to the client.

2020-07-07 09:33:25

From January to June 2020, Vietnam's industrial production index increased by 2.71% compared to the same period last year (2019).

2020-07-10 11:20:04

Agree