- Showing results for

- Machine Tools

The Smart Machinery Cloud Platform intends to standardize terminal software and hardware, application tools, and operation platforms to assist enterprises in their digital transformation.

2022-06-14 09:38:10

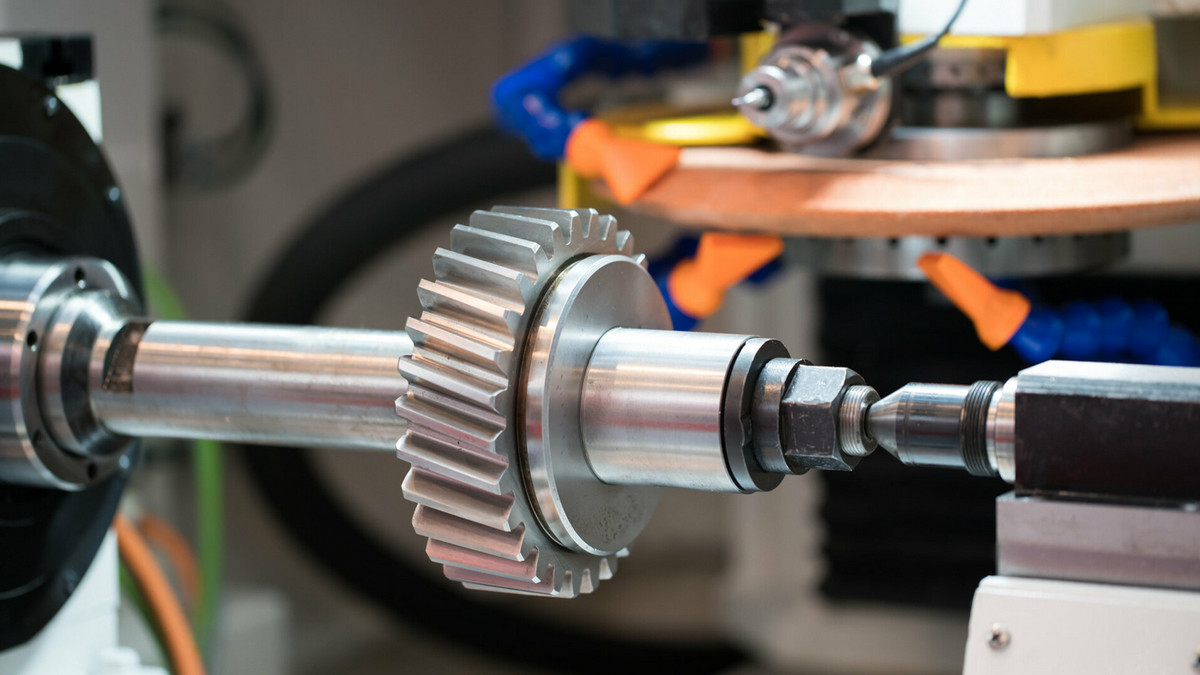

Broaching is a machining process that uses a toothed machining tool, called a broach, to cut material from a workpiece. The broach has a series of cutting tips arrayed in sequence on one tool. The cutting tips become progressively larger across the span of the tool. Across the span of the broach, the cutting tips will progress from rough cutter tips to fine cutter tips. The broach is inserted into a machine called a broaching machine, which drives the broach.

2022-06-17 10:31:09

Machine tool is a machine for manufacturing various machines and processing equipment, which occupies a key position in the national industrial development. In response to the global digital transformation, machine tools are also moving towards smart machines.

2022-06-20 09:59:09

A grinding wheel is a tool for grinding. It is composed of coarse-grained abrasive compounds bonded together. After forming a solid round object, grinding and abrasive processing can be performed on a grinding machine. Grinding is a commonly used processing method, which can obtain higher workpiece density and surface quality. Different grinding methods will produce different grinding defects. The most influential factor is the grinding wheel.

2022-06-27 13:18:28

Quick Die Change (SMED), or 10-minute die change, is a set of useful techniques for dealing with multiple batches of small quantities and improving the rapid response capability of the production system and is a type of lean production method. The point is to convert internal jobs to external job conversions as much as possible.

2022-06-28 16:45:38

Under the international consensus on carbon reduction, the wave of electric vehicles has swept the world and has become the focus of attention from all walks of life. It is predicted that the proportion of electric vehicles will increase significantly from 2030, and it is estimated that it will reach 55% of the global car market by 2040, surpassing the proportion of traditional fuel vehicles. In the era of electric vehicles, it will indirectly lead the machine tool industry to develop a new layout.

2022-06-30 11:08:09

To exert the cutting ability of the tool, the tool material needs to have significant progress and improvement. Various tool materials currently used have their characteristics to meet various processing requirements.

2022-07-01 14:57:16

The indexing plate is mainly used for milling machines, but also commonly used for drilling machines and surface grinders. It can be used for index drilling or milling, circumferential cutting, circumferential surface machining, straight line machining of planes and part of line segments.

2022-07-05 16:32:26

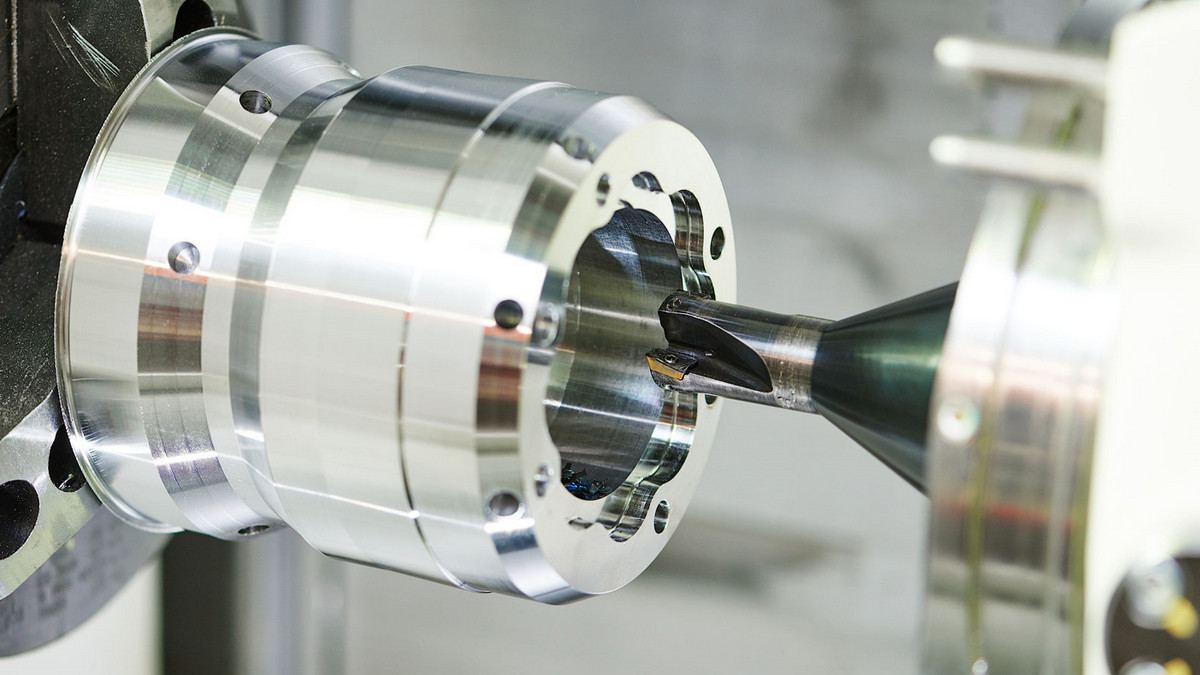

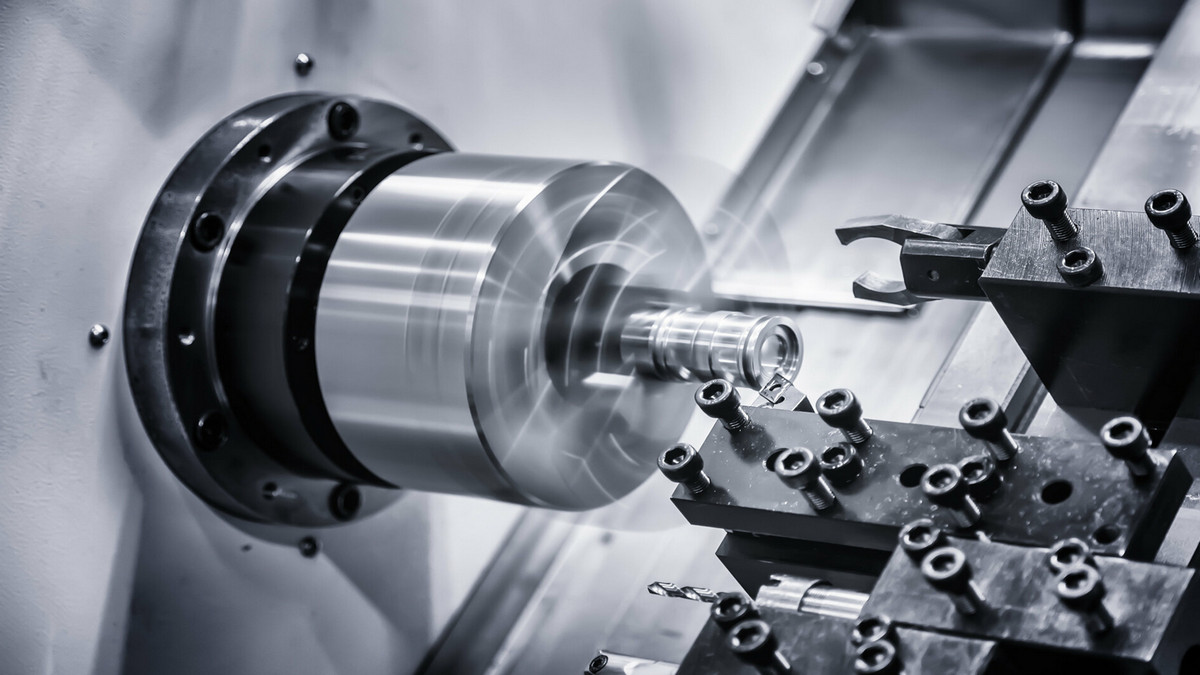

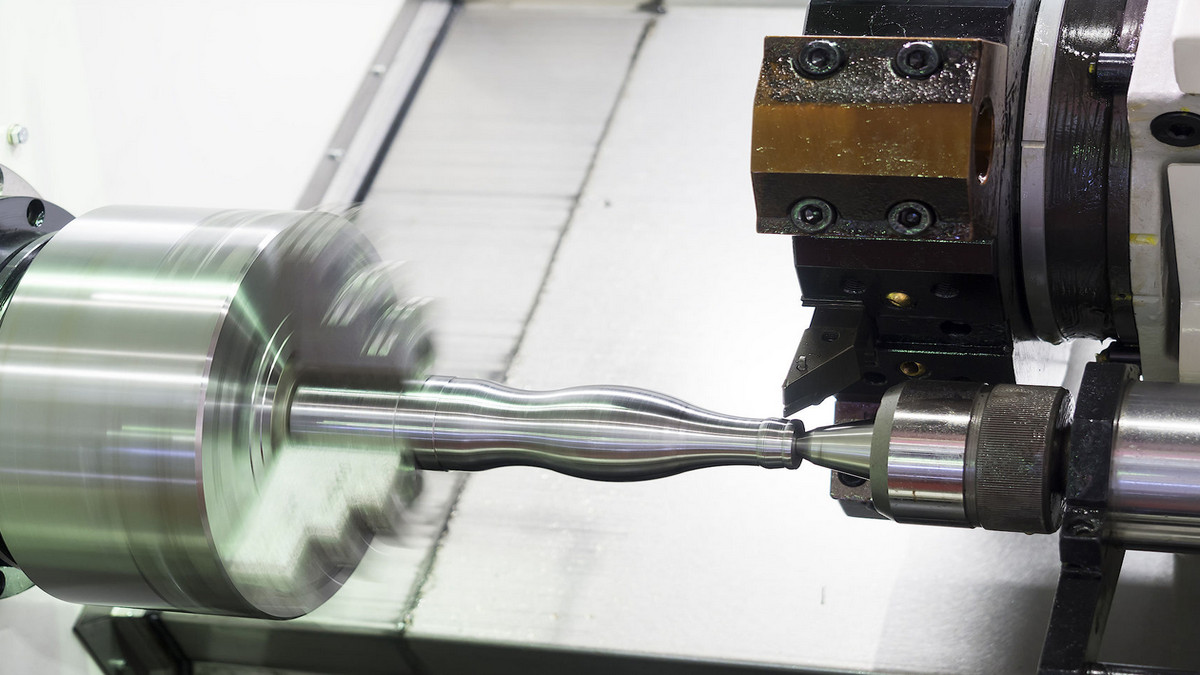

Lathe machines are used to remove excess material from a workpiece to give the workpiece the desired shape and size. Machining process designed for precision machining of relatively hard materials.

2022-07-19 11:21:42

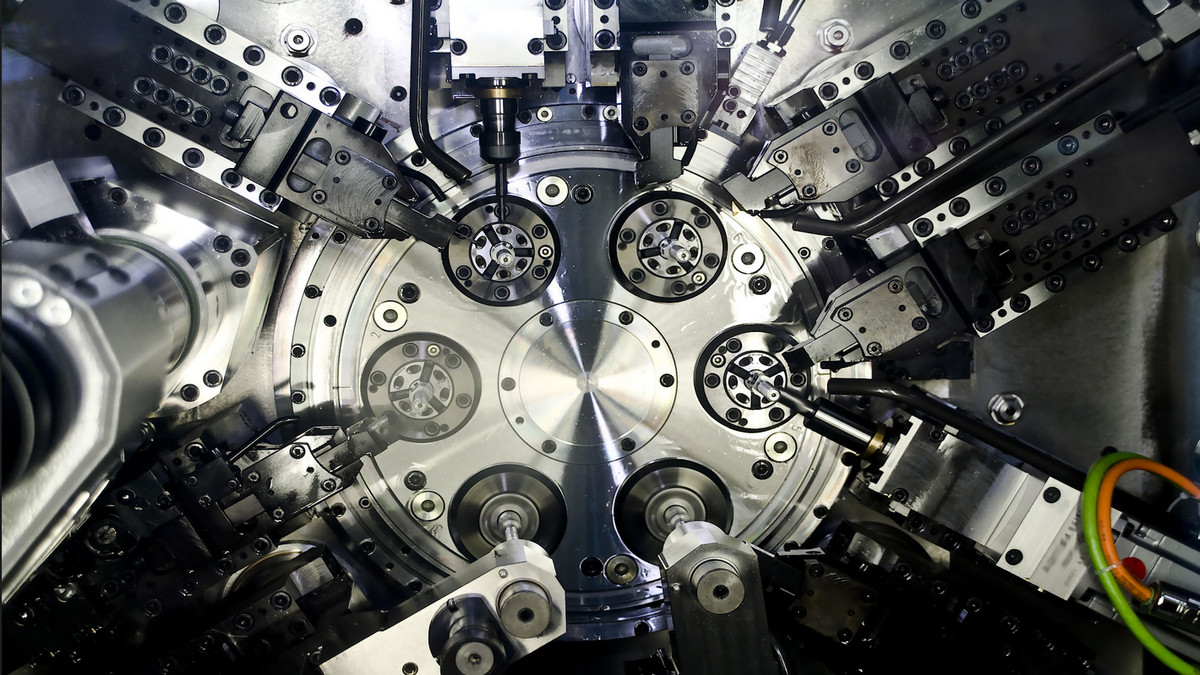

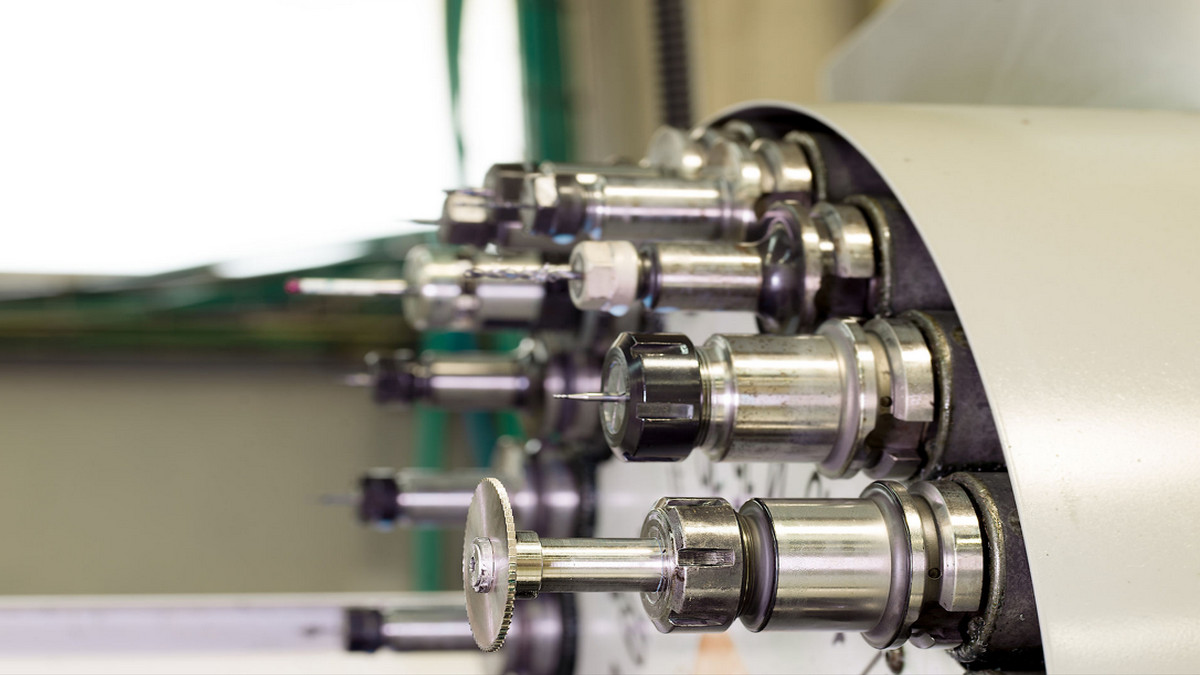

Five-axis CNC machining means that there are at least five coordinate axes (three linear coordinates and two rotary coordinates) on a machine tool, and can be processed simultaneously with coordinated movements under the control of the computer numerical control system. The axis of the CNC machine tool means the motion axis, which is actually a coordinate axis in space, such as the XY axis of the coordinates. There is no motion axis with an independent controller and motor drive system.

2022-07-19 16:31:54

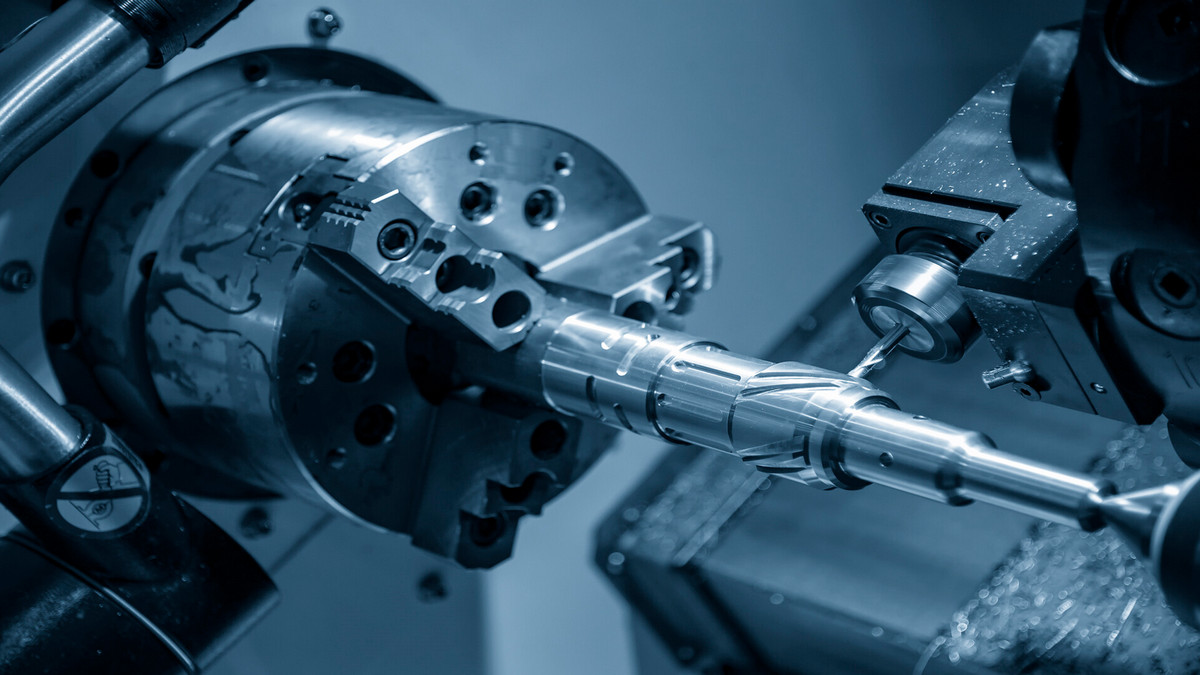

Milling is a machining method in which a milling cutter is used as a tool to process the surface of an object. Milling is a highly efficient machining method in which a rotating multi-blade tool is used to cut a workpiece.

2022-07-25 10:14:16

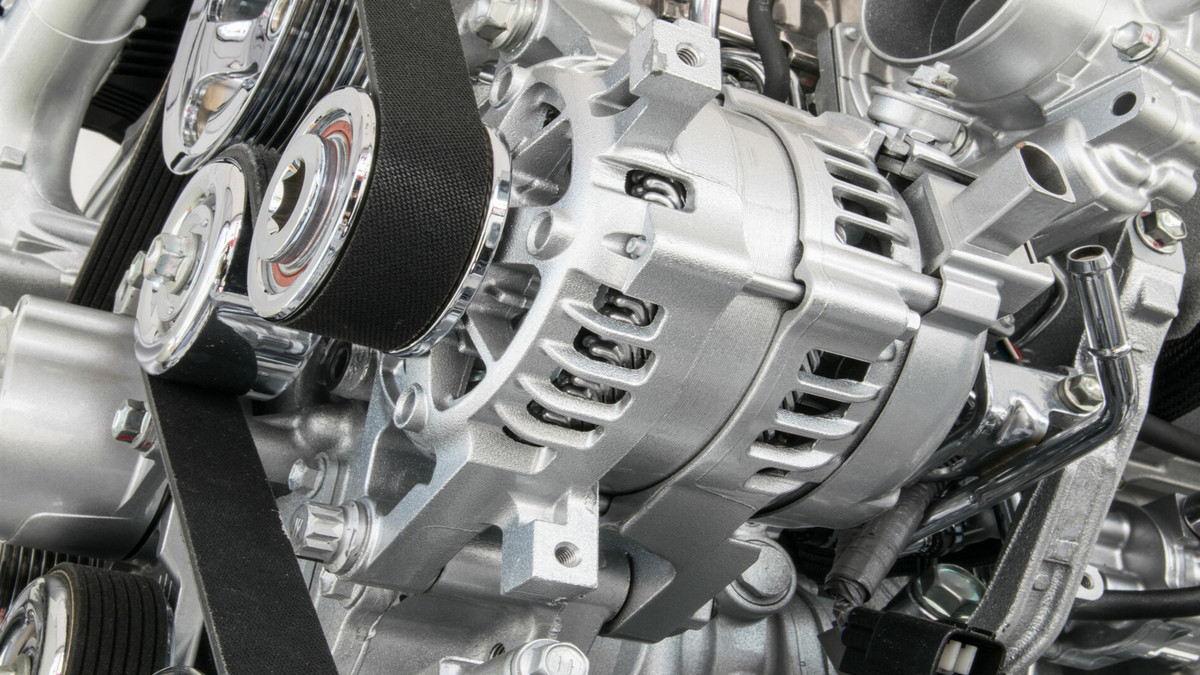

A method of transmitting rotational force between two separated shafts using pulleys and belts. The rotation speed ratio is inversely proportional to the diameter of the two pulleys, and it can slide when the load is excessive to prevent mechanical damage.

2022-08-05 16:44:32

The five-axis controller is the core of the five-axis processing machine, which is used to control the trajectory of the five-axis simultaneous motion and the compensation of the motion.

2022-08-11 14:52:03

Life is full of inventions that provide convenient services and entertainment: mobile phones, MRTs, notebooks, computers, cars, etc. These exquisite finished products presented to consumers are all processed by a series of complex processes and assembled. Among them, in the industrial process of the product, the machine tool has a very critical position, without it, it is impossible to produce equipment and parts, so it has won the title of "The Mother of Machinery". However, despite its important role, it is little known. Therefore, in this article, we will expose the state of the machine tool industry, understand its contribution to the manufacturing industry, and extend the visible development in the future.

2022-08-17 14:58:14

The process of milling a plane at right angles to the axis of rotation of the tool.

2022-08-29 14:27:06

The turning process is to make the material reach the desired shape by removing the material, and its machining accuracy is high and there is no mold restriction. But the production cost is high and the processing speed is slow.

2022-08-30 13:09:15

In addition to the use of hand tools, the processing of metal workpieces is mainly achieved by the machine tools, such as lathes, planers, milling machines, grinders, boring machines, drilling machines, etc. These machines have different performances to match the job requirements. In recent years, various industrial advanced countries have used machines to replace manpower, making the application of machine tools more extensive and important. Although the processing precision of milling machines and grinding machines is superior to that of planers, the price is more expensive than that of planers. Generally, planers are still used for many initial processing jobs in small and medium-sized factories. So, what exactly is a planer?

2022-08-30 15:34:06

The mechanical structure of the main drive system of the CNC machine tool has been greatly simplified, and the belt drive and gear drive have been canceled. Zero drive of the machine.

2022-09-06 09:44:54

Internal high-pressure forming technology is one of the lightweight forming technologies for auto parts, which relies on the liquid or gas as the transmission medium, uses the precise control of internal pressure, and the axial feeding, with the mold cavity, and finally makes the metal hollow blank form the integral complex variable section member. Internal high pressure forming equipment is suitable for manufacturing aerospace, nuclear power, petrochemical, drinking water system, pipe system, automotive and bicycle industries of complex shaped section hollow components.

2022-09-06 11:47:18

The U.S. machine tool industry is the industry that has been hit the most by this wave of epidemics, including smart machinery and Industry 4.0, which are still the unchanged development trends for machine tool manufacturers in the future.

2022-09-07 10:03:00

Agree